Introduction to Rotary Vacuum Evaporator

A rotary vacuum evaporator is a laboratory instrument used for solvent removal, concentration, and purification. It is composed of a vacuum pump, a heating bath, a rotating flask, and a condenser. The vacuum pump creates a vacuum environment that lowers the boiling point of the solvent. The rotating flask increases the surface area of the solvent, enhancing the evaporation process's efficiency. The condenser cools the evaporating solvent, condensing it back into a liquid form, which can be collected in a separate flask. Rotary evaporators are widely used in various industries, including pharmaceuticals, chemistry, food, and beverage, and more for solvent separation and purification.

Table of Contents

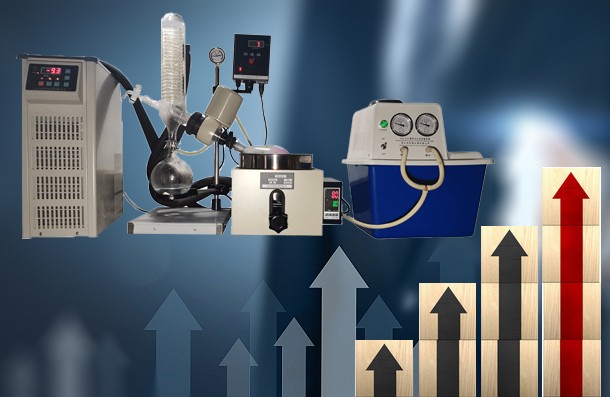

Major Components of a Rotary Evaporator

A rotary vacuum evaporator is a complex piece of equipment used to remove solvents efficiently and quickly. It consists of several major components that work together to achieve this goal. In this section, we will discuss the major components of a rotary evaporator and their functions.

Vacuum Pump

The vacuum pump is one of the most important components of a rotary vacuum evaporator. It is used to create a vacuum inside the system, reducing the boiling point of the solvent and allowing it to evaporate at lower temperatures.

Flask

The flask is another major component of a rotary vacuum evaporator. It is where the solution is placed, and it rotates to increase the surface area of the liquid, speeding up the solvent removal process.

Heating Bath

The heating bath is used to heat the solution and increase the rate of evaporation. It is a crucial component of the rotary vacuum evaporator, as it ensures that the solution reaches the required temperature for efficient solvent removal.

Condenser

The condenser is where the evaporated solvent is cooled and condensed back into a liquid, ready for collection in the collection flask. It is an essential component of the rotary vacuum evaporator, as it allows for the efficient recovery of solvents.

Collection Flask

The collection flask is where the condensed solvent is collected after it has been evaporated and condensed in the condenser. It is an important component of the rotary vacuum evaporator, as it ensures that the recovered solvents are safely collected and can be reused.

In conclusion, the major components of a rotary vacuum evaporator work together to remove solvents efficiently and quickly. The vacuum pump, flask, heating bath, condenser, and collection flask are all essential components of the rotary vacuum evaporator. By understanding the functions of each component, users can effectively use a rotary vacuum evaporator for solvent removal.

Uses and Applications of a Rotary Evaporator

A rotary evaporator, also known as a rotovap, is a powerful laboratory instrument that has various applications across different fields. Its ability to remove solvents efficiently and gently through evaporation has made it a valuable tool for many laboratory and industrial processes. Here are some of the most common uses and applications of a rotary evaporator:

Chemical Research and Analysis

Rotary evaporators are widely used in chemical research and analysis applications. They are used to concentrate and purify solutions, prepare samples for analysis, and extract natural products. The ability to remove solvents gently and efficiently makes rotary evaporators an essential tool in various chemical research applications.

Pharmaceutical Industry

Pharmaceutical companies use rotary evaporators in various applications, such as solvent removal, extraction, and purification of compounds. Rotary evaporators are used to process and purify natural products, prepare samples for quality control, and concentrate solutions. The gentle and efficient solvent removal capability of a rotary evaporator makes it an ideal tool in pharmaceutical research and development.

Petrochemical Industry

The petrochemical industry uses rotary evaporators to distill and purify crude oil samples, separate components from crude oil, and recover solvents from petrochemical processes. Rotary evaporators are also used to purify and concentrate essential oils and fragrances.

Food and Beverage Industry

Rotary evaporators are used in the food and beverage industry to extract and concentrate flavors and fragrances from various raw materials. They are also used to purify and distill alcoholic beverages, such as gin and whiskey.

Cannabis Industry

The cannabis industry uses rotary evaporators to extract and concentrate cannabis oils, separate and purify cannabinoids, and remove solvents from cannabis extracts. Rotary evaporators are also used to extract terpenes, which are essential oils found in cannabis plants.

In conclusion, rotary evaporators are essential laboratory instruments that have various uses and applications across multiple fields. They are used to remove solvents efficiently and gently through evaporation, making them valuable tools in chemical research and analysis, pharmaceuticals, petrochemicals, food and beverage, and cannabis industries.

The Process of Rotary Evaporation

The process of rotary evaporation involves several steps that require careful attention to detail and proper technique to ensure accurate and efficient solvent removal. Here's a step-by-step guide to using a rotary vacuum evaporator for solvent removal:

Step 1: Assemble the Apparatus

Before starting the process, assemble the rotary evaporator apparatus according to the manufacturer's instructions. Ensure that the equipment is clean and free from any defects.

Step 2: Load the Sample into the Flask

Load the sample into the evaporation flask and ensure that the flask is securely attached to the apparatus.

Step 3: Apply Heat and Vacuum

Switch on the rotary evaporator and apply heat to the sample using the heat bath. Reduce the pressure in the rotary evaporator using a vacuum pump. In doing so, the boiling point of the solvent will reduce.

Step 4: Rotate the Flask

Rotate the flask rapidly. As a result of the rapid rotation, the surface area of the sample will increase, which will facilitate a quicker evaporation process of the solvent.

Step 5: Collect the Condensed Solvent

The solvent evaporates and condenses in the condenser pipe. Collect the condensed solvent in a separate flask.

Step 6: Repeat the Process

Repeat the process until the desired amount of solvent has been removed from the sample.

Step 7: Cleaning the Equipment

Once the process is complete, switch off the rotary evaporator and disassemble the apparatus. Clean the equipment thoroughly according to the manufacturer's instructions.

The process of rotary evaporation is an effective technique for removing solvents from samples. By following a step-by-step guide and understanding the principles behind rotary evaporation, researchers can effectively and accurately remove solvents from their samples.

Overall, a rotary vacuum evaporator is a widely used laboratory equipment for solvent removal. By following these instructions, users can ensure the safe and efficient use of the rotary vacuum evaporator, which can ultimately improve the accuracy and reproducibility of their experiments.

Related Products

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Laboratory Benchtop Water Circulating Vacuum Pump for Lab Use