Toggle Categories

Get Instant Support

Choose your preferred way to connect with our team

-

Get Free Quote Fill out form for detailed pricing

-

Send Email Detailed inquiry support

-

WhatsApp Quick mobile chat

Response Time

Within 8 hours on working days, 24 hours on holidays

Sample Preparation

KinTek sample preparation equipment includes sample crushing,milling, as while as while sieving equipment, hydraulic press equipment includes manual press, electric press, isostatic press, hot press and press filtering machine.

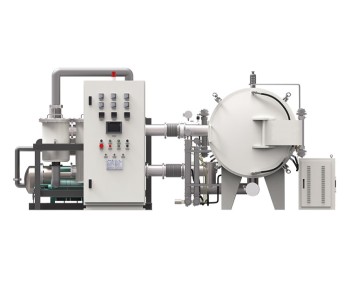

Thermal Equipment

KinTek supplies a broad range of high-temperature furnaces, including lab, pilot production, and industrial production furnaces, with a temperature range of up to 3000 ℃. One of KinTek's advantages is the ability to create custom-made furnaces tailored to specific functions, such as different heating methods and speeds, extra high and dynamic vacuums, controlled atmospheres and gas circuits, automated mechanical structures, and software and hardware development.

Lab Consumables & Materials

KinTek offers a range of lab consumables and materials, including evaporation materials, targets, metals, electrochemistry parts, as well as powders, pellets, wires, strips, foils, plates, and more.

Bio-Chem Equipment

KinTek bio-chem equipment comprises rotary evaporators, glass and stainless steel reactors, distillation systems, circulating heaters and chillers, as well as vacuum equipment.

Products

Infrared Heating Quantitative Flat Plate Press Mold

Item Number: PMHD

Double Plate Heating Press Mold for Lab

Item Number: PMD

Warm Isostatic Press for Solid State Battery Research

Item Number: PCIH

Isostatic Molding Pressing Molds for Lab

Item Number: PIPM

Square Lab Press Mold for Laboratory Applications

Item Number: PMS

Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

Item Number: PCIA

Cylindrical Press Mold for Lab Applications

Item Number: PMC

Special Heat Press Mold for Lab Use

Item Number: PCHF

Manual Cold Isostatic Pressing Machine CIP Pellet Press

Item Number: PCIM

Carbide Lab Press Mold for Laboratory Applications

Item Number: PMW

Assemble Square Lab Press Mold for Laboratory Applications

Item Number: PMAS

Assemble Lab Cylindrical Press Mold

Item Number: PMAC

XRF & KBR steel ring lab Powder Pellet Pressing Mold for FTIR

Item Number: PMXS

XRF & KBR plastic ring lab Powder Pellet Pressing Mold for FTIR

Item Number: PMXP

XRF Boric Acid Lab Powder Pellet Pressing Mold for Laboratory Use

Item Number: PMXB

Special Shape Press Mold for Lab

Item Number: PMT

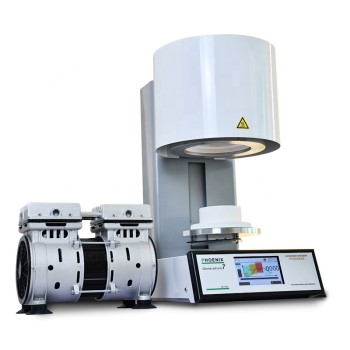

Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

Item Number: PMXA

Lab-Scale Vacuum Induction Melting Furnace

Item Number: KT-VI

Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

Item Number: KT-RFTF

Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

Item Number: KT-VTP

Vacuum Hot Press Furnace Machine Heated Vacuum Press

Item Number: KT-VHP

Electric Heated Hydraulic Vacuum Heat Press for Lab

Item Number: PPZ

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Articles

From Powder to Perfection: The Critical Choice Between Uniaxial and Isostatic Pressing

Uniaxial hot pressing shapes materials, but isostatic pressing (HIP) perfects them by eliminating hidden internal flaws. Understand the crucial difference.

The Thermodynamics of Ambition: Redefining High Temperature in Vacuum Furnaces

Discover why "high temperature" is relative in vacuum furnaces. From standard annealing to 2200°C sintering, learn how to match heat to material potential.

The Architecture of the Invisible: Mastering the CVD Tube Furnace

Chemical Vapor Deposition (CVD) turns gas into solid with atomic precision. Explore how this complex reactor system works and why it defines modern material science.

The Architecture of Control: Decoding the Five-Port Electrolytic Cell

Unlock the specifics of the standard five-port electrolytic cell (3x Φ6.2mm, 2x Φ3.2mm) and why precise customization is the key to reproducible electrochemistry.

Beyond Brute Force: Why the Strongest Materials Fail and How Your Lab Can Predict It

Learn why focusing on brute force is a mistake. Discover how understanding material microstructure—not just specs—prevents failure and how to fix it.

The Invisible Trade-off: Balancing Speed and Purity in Vacuum Quenching

Nitrogen offers speed; Argon offers purity. Discover the engineering psychology behind choosing the right quenching gas to balance cost against metallurgical integrity.

Beyond Brute Force: The Engineering Logic of Uniform Pressure

Discover how Cold Isostatic Pressing (CIP) uses hydrostatic force to create flawless components with uniform density, solving complex manufacturing challenges.

The Engineering of Nothingness: Why Perfection Requires a Vacuum

Vacuum furnaces trade atmospheric chaos for controlled purity. Explore how heat treating, brazing, and sintering in a void creates superior metallurgy.

The Engineer's Gambit: Why Molybdenum Defines the Modern Vacuum Furnace

Discover why molybdenum is key to vacuum furnace purity and how hot zone design dictates temperature uniformity in critical manufacturing processes.

The Architecture of Emptiness: How Vacuum Tube Furnaces Defy Entropy

Discover the precise engineering behind vacuum tube furnaces. Learn how thermal isolation and high-vacuum systems create the ultimate environment for material purity.

The Geometry of Heat: Navigating the Choice Between Tube and Box Furnaces

Discover the systemic difference between continuous tube furnaces and static box furnaces. Learn how workflow dictates your hardware choice.

The Architecture of Silence: Why Quartz Defines Electrochemical Precision

In electrochemistry, the vessel is as critical as the catalyst. Discover why quartz's unique properties make it the unseen hero of precise experimentation.

The Physics of Permanence: Why a T-Shirt Press and a Circuit Bonder Are the Same, Yet Worlds Apart

Hot press machines use controlled heat and pressure, but the psychology of risk dictates their design—from simple transfers to mission-critical electronics.

The Art of Absence: Why Advanced Materials Demand Vacuum Furnaces

Discover why the absence of air is critical for advanced heat treatment. Learn how vacuum furnaces prevent oxidation and ensure material integrity.

The Physics of Perfection: Why a Vacuum Is the Material Scientist's Most Powerful Tool

Vacuum hot pressing achieves near-perfect material density by using a vacuum to eliminate microscopic gas voids, a critical step for high-performance components.

The Architecture of Heat: Why Precision is the Only Variable That Matters

A tube furnace is more than an oven; it is a system of isolation and control. Explore the engineering behind thermal uniformity and atmosphere management.

The Silent Efficiency of the Void: Mastering Heat Transfer in Vacuum Furnaces

Discover why vacuum furnaces reject convection for radiation. A deep dive into the physics of purity, line-of-sight heating, and precision control.

The Thermodynamics of Restraint: Precision, Entropy, and the Art of the Five-Port Cell

The line between routine maintenance and catastrophic failure is often defined by ego. Learn when to clean, when to stop, and when to call a professional.

The War Against Voids: Mastering Material Density with Heat and Pressure

Hot pressing uses graphite tooling to apply extreme heat and pressure, eliminating microscopic voids to forge ultra-dense, high-performance materials.

The Architecture of Emptiness: Achieving Metallurgical Perfection in a Vacuum

Vacuum furnaces offer more than just heat; they offer total environmental control. Explore the physics of radiative heating, outgassing, and why the void is essential for purity.