Vacuum Hot Press Furnace

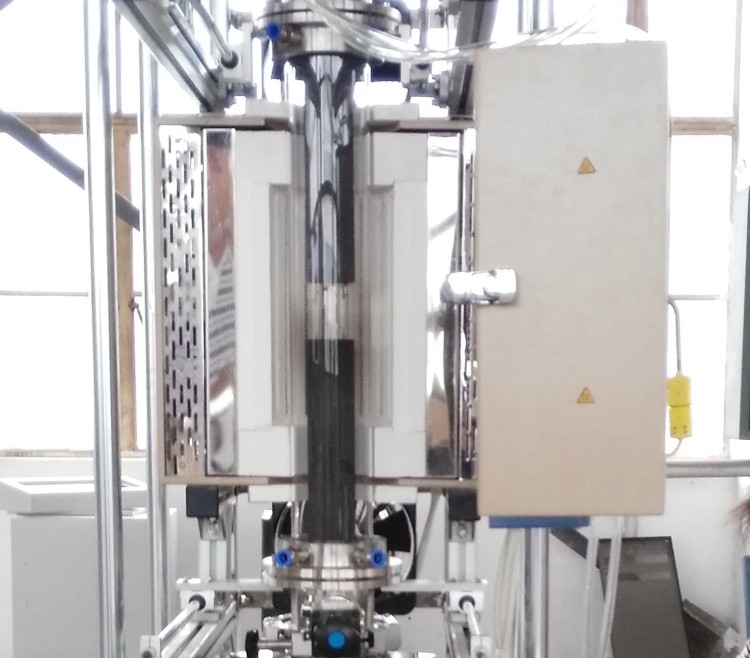

Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

Item Number : KT-VTP

Price varies based on specs and customizations

- Hydraulic press working pressure

- 0-30 Mpa

- Vertical split furnace working temperature

- ≤1150 ℃

- Heating speed

- <15 ℃/min

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Introduction

A Vacuum Tube Hot Press Furnace is a combination of vacuum/atmosphere, hot pressing forming and high temperature sintering. It is suitable for high temperature hot forming of new materials such as dry powder metallurgy and functional ceramics. Vacuum sintering of alloy materials composed of metals and high-temperature sintering of ceramic materials silicon carbide and silicon nitride can also be used for dry powder or crushing at a low temperature of the melting point of the main component. Metallurgically bonded to increase its strength.

Application

Vacuum Tube Hot Press Furnaces are widely used in various industries and research fields, offering precise and efficient heating and pressing capabilities. Here are some of their main application areas:

- Sintering of ceramic materials, such as high-performance ceramics, electronic ceramics, and refractory materials

- Hot pressing of metal powders, including hard metals, porous metals, and composite materials

- Heat treatment of materials, such as annealing, hardening, and tempering

- Crystal growth and synthesis of advanced materials

- Production of carbon-carbon composites and other high-temperature composites

- Vacuum brazing and welding

- Research and development of new materials and processes

Features

The Vacuum Hot Press Furnace is a comprehensive set of equipment designed to heat and pressurize materials under controlled conditions, whether in a vacuum or atmospheric environment. This advanced system is tailored to meet the specific needs of various materials and heating temperatures, offering a range of heating elements such as graphite heaters, molybdenum heaters, and induction heating. The furnace supports both one-way and two-way pressurization through a hydraulic system, ensuring precise control over the pressing process.

Key features of the Vacuum Hot Press Furnace include:

- Versatile Heating Elements: The furnace accommodates different heating elements like graphite and molybdenum heaters, as well as induction heating, allowing for flexibility in processing a wide range of materials at varying temperatures.

- Precise Pressurization Control: With options for one-way or two-way pressurization, the hydraulic system ensures that materials are subjected to the exact pressure required for optimal sintering and compaction.

- Enhanced Material Bonding: Under high temperature and pressure, the furnace facilitates the bonding of raw material particles, promoting grain growth and reducing voids and grain boundaries, which leads to a denser, more compact sintered body.

- Comprehensive System Integration: The furnace is equipped with a robust structure that includes a furnace body, furnace doors, heating and heat preservation systems, temperature measurement systems, vacuum systems, air charging systems, water cooling systems, and a sophisticated control system, all working in harmony to ensure precise and efficient operation.

- Vacuum Environment Optimization: The hot press is designed to operate within a vacuum negative pressure box, which is crucial for preventing oxidation and other adverse reactions during the hot pressing process, thus maintaining the purity and integrity of the materials being processed.

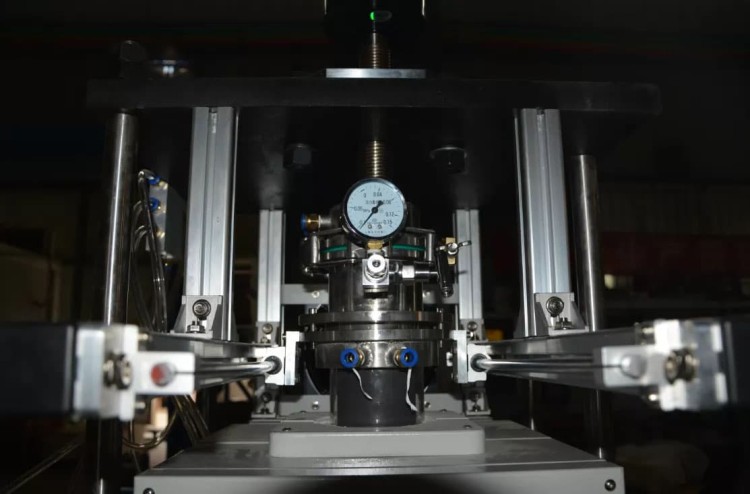

Detail & Parts

Principle

The split vertical heating furnace body is adopted for the vacuum tubular furnace, the vacuum hot pressing chamber is sealed with high temperature furnace tube and stainless steel flange, and the pressure stroke adopts the vacuum corrugated pipe for up and down movement under vacuum state; The electric hydraulic press machine is used for the pressure generating, and the pressure column is made of graphite rod and graphite mold. When powder is heated to the target sintering temperature while pressurized, the target materials can be sintered into dense and uniform products in a short time.

Advantages

- High-temperature accuracy: The advanced touch screen auto temperature controller ensures precise temperature control, providing accurate and reliable results.

- Easy operation: The user-friendly 7-inch touch screen English image interface simplifies operation, making it accessible even for novice users.

- Programmable sintering curves: Up to 15 sintering curves can be preset, allowing for customized heating and cooling profiles to suit specific materials and processes.

- Real-time monitoring: The graphical representation of the sintering curve provides a clear visual overview of temperature changes throughout the process.

- Versatile atmosphere control: The optional gas flowmeter enables atmosphere sintering, allowing for precise control of the gas environment during processing.

- Remote control and data logging: Optional modules can be added to enable remote control and data downloading, facilitating efficient process monitoring and data analysis.

- Wide applications: This Vacuum Tube Furnace finds applications in various fields, including university and research labs, as well as industrial production settings.

- Excellent heat insulation: The furnace's superior heat insulation ensures efficient energy utilization and minimizes heat loss, resulting in cost savings.

- Uniform temperature distribution: The symmetrical heating design ensures uniform temperature distribution within the furnace chamber, promoting consistent and high-quality results.

- Vacuum and inert atmosphere compatibility: The furnace can operate under both vacuum and inert atmosphere conditions, providing flexibility for various processing requirements.

| Hydraulic press | Working pressure: 0-30Mpa Travel distance: <50mm Pressure stability: ≤1MPa/10min Pressure meter: Digital pressure gauge Drive solution: Electric drive with standby manual drive |

|---|---|

| Vertical split furnace | Working temperature: ≤1150℃ Heating element:Ni-Cr-Al resistance wire with dipped Mo Heating speed: <15℃/min Hot zone length: 300mm Constant temperature zone: 100mm Controller: Touch screen with PID thermal controller Rated power: 2200W |

| Vacuum furnace tube | Tube material: Quartz tube(Optional Alumina/Nickel alloy) Tube diameter: 100mm(Optional 120/160mm) Vacuum sealing: SS flange with silicon O ring Flange cooling method: Inter layer water circulating cooling |

| Graphite pressing die | Die material: High purity graphite (Graphite must work under vacuum to prevent oxidation) Pressure rod diameter: 87mm Sleeve die size: 55mm OD/ 50mm Height Die inserts: OD22.8 x ID20.8 Pushing Rod: 12.7mmOD/40mm Height Other sizes die can be customer made |

| Vacuum pump setup | Rotary vane pump vacuum is up to 10-2 torr Turbo pump station vacuum is up to 10-4 torr |

| Electric power supply | AC110-220V, 50/60HZ |

Warnings

Operator safety is the top important issue! Please operate the equipment with cautions. Working with inflammable& explosive or toxic gases is very dangerous, operators must take all necessary precautions before starting the equipment. Working with positive pressure inside the reactors or chambers is dangerous, operator must fellow the safety procedures strictly. Extra caution must also be taken when operating with air-reactive materials, especially under vacuum. A leak can draw air into the apparatus and cause a violent reaction to occur.

Designed for You

KinTek provide deep custom made service and equipment to worldwide customers, our specialized teamwork and rich experienced engineers are capable to undertake the custom tailoring hardware and software equipment requirements, and help our customer to build up the exclusive and personalized equipment and solution!

Would you please drop your ideas to us, our engineers are ready for you now!

Trusted by Industry Leaders

FAQ

What Is A Tube Furnace?

Laboratory tube furnace is one classic external heating high temperature tube furnace, also named hot wall heating furnace.

According to the different working temperature, furnace tube material usually can be transparent quartz tubes, high purity alumina ceramic tubes and high strength metal alloy tubes.

To meet different thermal researching purposes, tube furnace can be designed with multi heating zones, so as to have a flexible control of temperature gradient in the tube working chamber; furnace tube can work with a controlled atmosphere working environment or a high vacuum working environment.

What Is A Vacuum Furnace Used For?

What Are The Advantages Of Using A Hydraulically Heated Laboratory Press?

What Is The Purpose Of A Vacuum Hot Press Furnace?

How Does A Tube Furnace Work?

Tube furnace heating elements are placed surrounding the cylindrical cavity, furnace can only heat the samples in the cylindrical cavity through indirect thermal radiation, since furnace tube can prevent sample material from contacting with furnace heating elements and insulation materials, so tube furnace creates a clean isolated heat chamber and reduce risks of the sample material contaminating by the furnace.

What Is The Process Of A Vacuum Furnace?

What Is A Rotary Tube Furnace?

What Does A Hydraulic Lab Heat Press Do?

What Are The Advantages Of A Vacuum Hot Press Furnace?

What Is The Application For Tube Furnace?

Tubular furnace is mainly used in metallurgy, glass, heat treatment, lithium anode and cathode materials, new energy, abrasives and other industries, and is a professional equipment for measuring materials under certain temperature conditions.

Tube furnace features simple structure, easy operation, easy control and continuous production.

Tube furnace is also widely applied in the CVD (chemical vapor deposition) and plasma enhanced CVD systems.

What Gas Is Used In A Vacuum Furnace?

How Does A Rotary Tube Furnace Work?

What Types Of Samples Or Materials Can Be Processed In A Hydraulically Heated Laboratory Press?

How Does A Vacuum Hot Press Furnace Work?

How Many Different Types Tube Furnace?

Tube furnace can work with different mechanical functions smoothly, so there are many different types tube furnace variations for different experiment purposes, typical furnace furnaces are as below:

- Horizontal tube furnace

- Vertical tube furnace

- Split tube furnace

- Rotary tube furnace

- Tilting tube furnace

- Sliding tube furnace

- Fast heating and cooling tube furnace

- Continuous feeding and discharging tube furnace

What Is The Heating Element Used In A Vacuum Furnace?

What Are The Advantages Of A Rotary Tube Furnace?

What Is The Function Of Rotary Tube Furnace?

How Does A Hydraulically Heated Laboratory Press Work?

What Are The Common Applications Of Vacuum Hot Press Furnaces?

What Are The Advantages Of Using A Tube Furnace?

What Are The Advantages Of Rotary Tube Furnace?

How Can The Performance Of A Hydraulically Heated Laboratory Press Be Optimized?

What Factors Should Be Considered When Selecting A Vacuum Hot Press Furnace?

What Safety Precautions Should Be Taken When Using A Tube Furnace?

4.7 / 5

Received the furnace in a timely manner. Works like a charm. Thank you!

4.8 / 5

Excellent product! Fast delivery and great customer service.

4.9 / 5

The furnace is of high quality and has been a great addition to our lab.

4.6 / 5

Very satisfied with this product. It's durable and easy to use.

4.7 / 5

The vacuum tube furnace is a great value for the price. It's also very user-friendly.

4.8 / 5

This furnace is a real workhorse. It's been running non-stop for weeks and hasn't missed a beat.

4.9 / 5

The technical support from KINTEK SOLUTION is top-notch. They helped me troubleshoot a minor issue quickly and easily.

4.7 / 5

The furnace is very well-made and has all the features I need. I would definitely recommend it to others.

4.8 / 5

Great product! The vacuum tube furnace is easy to use and produces high-quality results.

4.9 / 5

Very happy with my purchase. The furnace is a great addition to my lab.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Laboratory High Pressure Vacuum Tube Furnace

KT-PTF High Pressure Tube Furnace: Compact split tube furnace with strong positive pressure resistance. Working temp up to 1100°C and pressure up to 15Mpa. Also works under controller atmosphere or high vacuum.

Vacuum Hot Press Furnace Machine for Lamination and Heating

Experience clean and precise lamination with Vacuum Lamination Press. Perfect for wafer bonding, thin-film transformations, and LCP lamination. Order now!

600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

Discover the 600T Vacuum Induction Hot Press Furnace, designed for high-temperature sintering experiments in vacuum or protected atmospheres. Its precise temperature and pressure control, adjustable working pressure, and advanced safety features make it ideal for nonmetal materials, carbon composites, ceramics, and metal powders.

Multi Heating Zones CVD Tube Furnace Machine Chemical Vapor Deposition Chamber System Equipment

KT-CTF14 Multi Heating Zones CVD Furnace - Precise Temperature Control and Gas Flow for Advanced Applications. Max temp up to 1200℃, 4 channels MFC mass flow meter, and 7" TFT touch screen controller.

Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

The lab press for vacuum box is a specialized piece of equipment designed for laboratory use. Its main purpose is to press pills and powders according to specific requirements.

Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

Efficient split chamber CVD furnace with vacuum station for intuitive sample checking and quick cooling. Up to 1200℃ max temperature with accurate MFC mass flowmeter control.

Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

Enhance your lab's precision with our lab press for vacuum box. Press pills and powders with ease and precision in a vacuum environment, reducing oxidation and improving consistency. Compact and easy to use with a digital pressure gauge.

Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

The air pressure sintering furnace is a high-tech equipment commonly used for the sintering of advanced ceramic materials. It combines vacuum sintering and pressure sintering techniques to achieve high-density and high-strength ceramics.

Vacuum Heat Treat Furnace with Ceramic Fiber Liner

Vacuum furnace with polycrystalline ceramic fiber insulation liner for excellent heat insulation and uniform temperature field. Choose from 1200℃ or 1700℃ max. working temperature with high vacuum performance and precise temperature control.

Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

Efficiently process heat-pressing samples with our Integrated Manual Heated Lab Press. With a heating range up to 500°C, it's perfect for various industries.

Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

Discover the versatility of Laboratory Rotary Furnace: Ideal for calcination, drying, sintering, and high-temperature reactions. Adjustable rotating and tilting functions for optimal heating. Suitable for vacuum and controlled atmosphere environments. Learn more now!

Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

A vacuum molybdenum wire sintering furnace is a vertical or bedroom structure, which is suitable for withdrawal, brazing, sintering and degassing of metal materials under high vacuum and high temperature conditions. It is also suitable for dehydroxylation treatment of quartz materials.

Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

Experience efficient material processing with our vacuum-sealed rotary tube furnace. Perfect for experiments or industrial production, equipped with optional features for controlled feeding and optimized results. Order now.

Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

Efficiently prepare your samples with our Split Manual Heated Lab Press. With a pressure range up to 40T and heating plates up to 300°C, it's perfect for various industries.

High Temperature Alumina (Al2O3) Furnace Tube for Engineering Advanced Fine Ceramics

High temperature alumina furnace tube combines the advantages of high hardness of alumina, good chemical inertness and steel, and has excellent wear resistance, thermal shock resistance and mechanical shock resistance.

Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

Get precise dental results with Dental Vacuum Press Furnace. Automatic temperature calibration, low noise tray, and touch screen operation. Order now!

Horizontal High Temperature Graphite Vacuum Graphitization Furnace

Horizontal Graphitization Furnace: This type of furnace is designed with the heating elements placed horizontally, allowing for uniform heating of the sample. It's well-suited for graphitizing large or bulky samples that require precise temperature control and uniformity.

Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

IGBT experimental graphitization furnace, a tailored solution for universities and research institutions, with high heating efficiency, user-friendliness, and precise temperature control.

Vacuum Arc Induction Melting Furnace

Discover the power of Vacuum Arc Furnace for melting active & refractory metals. High-speed, remarkable degassing effect, and free of contamination. Learn more now!

Related Articles

The Physics of Perfection: Why a Vacuum Is the Material Scientist's Most Powerful Tool

Vacuum hot pressing achieves near-perfect material density by using a vacuum to eliminate microscopic gas voids, a critical step for high-performance components.

From Dust to Density: The Microstructural Science of Hot Pressing

Hot pressing isn't just shaping material; it's a micro-engineering process that eliminates hidden voids to create parts with near-perfect density and strength.

Defeating the Void: The Quiet Power of Vacuum Hot Pressing

Learn how vacuum hot pressing combines heat, pressure, and a controlled atmosphere to eliminate porosity and forge ultra-dense advanced materials.

Vacuum Hot Press Furnace: A Comprehensive Guide

Gain in-depth knowledge of Vacuum Hot Press Furnaces, their components, benefits, and applications in various industries. Explore how these furnaces revolutionize material processing and achieve exceptional results.

The Pressure Paradox: Why More Isn't Always Better in Hot Press Sintering

Increasing pressure in hot press sintering speeds densification but risks hidden flaws like anisotropy. Mastering this trade-off is key to superior materials.

Comprehensive Guide to Vacuum Hot Press Furnace Application

The Vacuum Hot Press Furnace is a versatile tool especially suited for sintering experiments involving non-metallic materials, carbon composites, ceramic materials and metal powder materials.

Beyond Heat: How Pressure Forges Near-Perfect Materials

Hot pressing uses uniaxial pressure with heat to eliminate porosity, achieving near-theoretical material density faster than sintering alone.

Molybdenum Vacuum Furnace: High-Temperature Sintering and Advanced Applications

Explore the advanced features and applications of molybdenum vacuum furnaces in high-temperature sintering and material treatment. Learn about their construction, control systems, and maintenance tips.

Comprehensive Guide to Spark Plasma Sintering Furnaces: Applications, Features, and Benefits

Explore the advanced features and applications of Spark Plasma Sintering Furnaces (SPS) in material science. Learn how SPS technology offers rapid, efficient, and versatile sintering for various materials.

Molybdenum Vacuum Furnace: High-Temperature Sintering and Heat Treatment

Explore the advanced features and applications of molybdenum vacuum furnaces in high-temperature sintering and heat treatment. Learn about their construction, control systems, and maintenance tips.

Introducing the Lab Vacuum Tube Furnaces

A vacuum tube furnace is a type of furnace that uses vacuum to isolate the process atmosphere from the external atmosphere.

Your Furnace Hit the Right Temperature. So Why Are Your Parts Failing?

Your vacuum furnace reaches temperature but ruins your parts? Learn the hidden cause of failure and how choosing the right hot zone material ensures perfect results.