fine ceramics

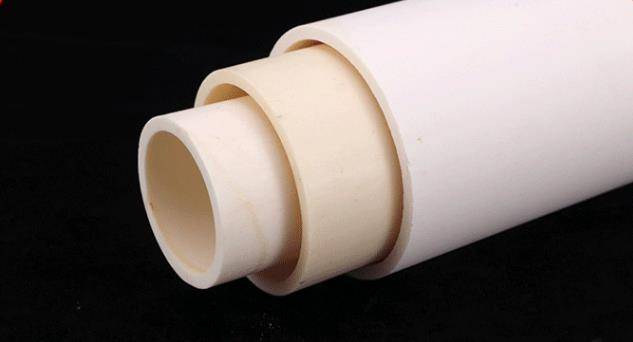

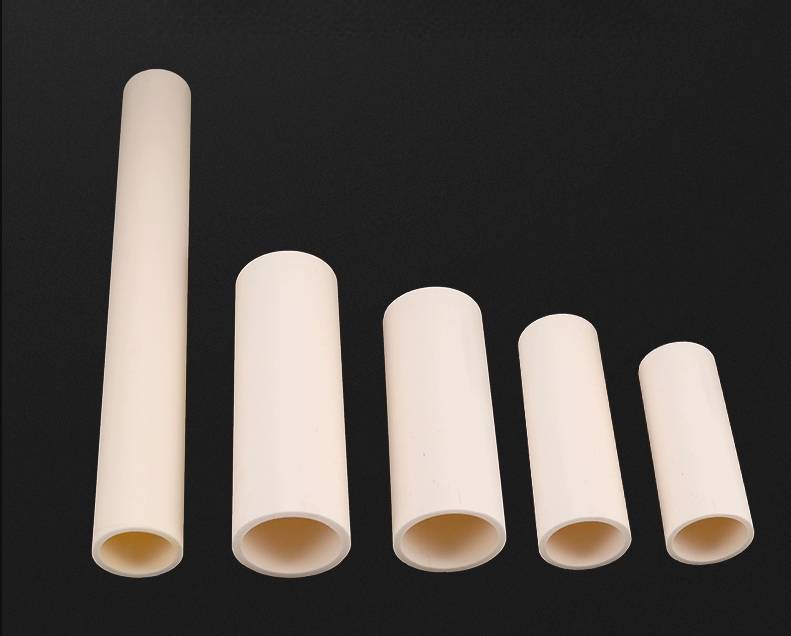

High Temperature Alumina (Al2O3) Furnace Tube for Engineering Advanced Fine Ceramics

Item Number : KM-C06

Price varies based on specs and customizations

- Material

- Aluminum oxide

- Specification

- See the form

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Application

High temperature alumina furnace tube are very durable and ideal for the heating industry. Unlike electric heaters, heaters made of alumina ceramic can efficiently reach and maintain the desired temperature, ensuring safer operation. In addition, its excellent high temperature resistance makes it an important part of temperature measuring devices and temperature control equipment. High-purity alumina tubing has excellent thermal resistance, allowing it to withstand extremely high temperatures under reducing, inert, or high vacuum conditions. These tubing maintain excellent chemical resistance and exhibit significant abrasion resistance even at elevated temperatures. In fact, 99.6% of alumina tubes can withstand temperatures as high as 1800°C.

- Ceramic furnace tubes: These tubes are used in ceramic furnaces as open single hole tubes. They can withstand high temperatures and provide excellent thermal stability, making them suitable for a variety of heat treatment processes.

- Square ceramic tubes for corona electrodes: Square alumina tubes can be used as corona electrodes in applications such as corona treatment. They have excellent electrical insulation and corrosion resistance properties.

Detail & Parts

Technical specifications

| outer 4mm inner 2mm (1 meter) | outer 12mm inner 8nn (1 meter) | outer 25mm inner 19mm (1 meter) | outer 45mm inner 36mm (1 meter) | outer 70mm inner 60mm (1 meter) |

| outer 5mm inner 3mm (1 meter) | outside 16mm inside 11mm (1 meter) | outside 30mm inside 24mm (1 meter) | outside 50mm inside 40mm (1 meter) | outer 80mm inner 70mm (1 meter) |

| outer 6mm inner 4mm (1 meter) | outer 18mm inner 13mm (1 meter) | outer 32mm inner 26mm (1 meter) | outer 55mm inner 45mm (1 meter) | outside 90mm inside 80mm (1 meter) |

| outer 8mm inner 5mm (1 meter) | outside 20mm inside 15mm (1 meter) | outer 35mm inner 28mm (1 meter) | outside 60mm inside 50mm (1 meter) | 90mm outside 100mm inside (1 meter) |

| outside 10mm inside 6mm (1 meter) | outer 22mm inner 16mm (1 meter) | outer 40mm inner 32mm (1 meter) | outer 65mm inner 55mm (1 meter) |

The produce we show are available in different sizes and custom sizes are available on request.

Advantages

- High mechanical strength and hardness: Alumina protective tube has high mechanical strength and hardness, which can resist breakage and wear even under harsh working conditions.

- Very high wear resistance: They can withstand aggressive environments such as mixed acids, bromine and halogens.

- Good Electrical Insulation: Makes it ideal for electrical components and applications where electrical insulation is critical.

- Low Dielectric Constant and Dielectric Loss: They have minimal energy loss in high frequency applications and exhibit excellent electrical properties.

- Excellent corrosion resistance: guarantees long service life and reliability in corrosive environments. They are chemically resistant and stable even at high temperatures

- Good High Temperature Resistance: These tubes can withstand high temperatures without deformation or degradation, making them suitable for use in furnace fabrication, heat exchangers, laser tubes, and other high temperature industrial applications.

In short, the alumina protection tube has the characteristics of high temperature resistance, chemical corrosion resistance, wear resistance, and electrical insulation. Its superior performance makes it a reliable choice for harsh environments where durability and performance are critical.

Trusted by Industry Leaders

FAQ

What Is A Tube Furnace?

Laboratory tube furnace is one classic external heating high temperature tube furnace, also named hot wall heating furnace.

According to the different working temperature, furnace tube material usually can be transparent quartz tubes, high purity alumina ceramic tubes and high strength metal alloy tubes.

To meet different thermal researching purposes, tube furnace can be designed with multi heating zones, so as to have a flexible control of temperature gradient in the tube working chamber; furnace tube can work with a controlled atmosphere working environment or a high vacuum working environment.

What Are Advanced Ceramics?

What Are Engineering Ceramics?

What Are The Main Applications Of Fine Ceramics?

How Does A Tube Furnace Work?

Tube furnace heating elements are placed surrounding the cylindrical cavity, furnace can only heat the samples in the cylindrical cavity through indirect thermal radiation, since furnace tube can prevent sample material from contacting with furnace heating elements and insulation materials, so tube furnace creates a clean isolated heat chamber and reduce risks of the sample material contaminating by the furnace.

What Are The Main Types Of Advanced Ceramics?

What Are The Main Types Of Engineering Ceramics?

What Are The Main Types Of Fine Ceramics?

What Is The Application For Tube Furnace?

Tubular furnace is mainly used in metallurgy, glass, heat treatment, lithium anode and cathode materials, new energy, abrasives and other industries, and is a professional equipment for measuring materials under certain temperature conditions.

Tube furnace features simple structure, easy operation, easy control and continuous production.

Tube furnace is also widely applied in the CVD (chemical vapor deposition) and plasma enhanced CVD systems.

What Are The Applications Of Advanced Ceramics?

What Are The Applications Of Engineering Ceramics?

What Is The Principle Behind Fine Ceramics?

How Many Different Types Tube Furnace?

Tube furnace can work with different mechanical functions smoothly, so there are many different types tube furnace variations for different experiment purposes, typical furnace furnaces are as below:

- Horizontal tube furnace

- Vertical tube furnace

- Split tube furnace

- Rotary tube furnace

- Tilting tube furnace

- Sliding tube furnace

- Fast heating and cooling tube furnace

- Continuous feeding and discharging tube furnace

How Are Advanced Ceramics Manufactured?

How Do Engineering Ceramics Differ From Traditional Ceramics?

What Are The Advantages Of Using Fine Ceramics?

What Are The Advantages Of Using A Tube Furnace?

What Are The Advantages Of Using Advanced Ceramics?

What Are The Advantages Of Using Alumina Ceramics?

What Safety Precautions Should Be Taken When Using A Tube Furnace?

What Is The Difference Between Alumina And Zirconia Ceramics?

Why Are Zirconia Ceramics Preferred In Certain Applications?

Why Are Silicon Carbide Ceramics Used In High-temperature Applications?

What Makes Silicon Carbide Ceramics Suitable For High-temperature Applications?

What Makes Boron Nitride Ceramics Unique?

How Are Boron Nitride Ceramics Used In Electronics?

How Do Advanced Ceramics Contribute To Energy Efficiency?

What Is The Manufacturing Process Of Engineering Ceramics?

Can Engineering Ceramics Be Customized For Specific Applications?

4.8 / 5

These alumina tubes are a must-have for any laboratory. They are incredibly sturdy and durable, and they can withstand extremely high temperatures.

4.9 / 5

I was very impressed with the quality of these alumina tubes. They are made from high-purity materials and they are very well-constructed.

4.7 / 5

These tubes are a great value for the price. They are very affordable and they last a long time.

4.8 / 5

I have been using these alumina tubes for several months now and I have been very happy with them. They are very reliable and they have never failed me.

4.9 / 5

I would highly recommend these alumina tubes to anyone who is looking for a high-quality product that will last for years.

4.7 / 5

These tubes are very easy to install and use. I was able to get them up and running in just a few minutes.

4.8 / 5

I am very impressed with the customer service from KINTEK SOLUTION. They were very helpful and they answered all of my questions.

4.9 / 5

I would definitely buy these alumina tubes again. They are a great product and they are worth the price.

4.7 / 5

These tubes are very versatile and they can be used for a variety of applications. I have used them for both high-temperature and low-temperature applications.

4.8 / 5

I am very happy with these alumina tubes. They are a great addition to my laboratory.

4.9 / 5

I would highly recommend these alumina tubes to anyone who is looking for a high-quality product that will last for years.

4.7 / 5

These tubes are very easy to install and use. I was able to get them up and running in just a few minutes.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

High Temperature Wear-Resistant Alumina Al2O3 Plate for Engineering Advanced Fine Ceramics

High temperature wear-resistant insulating alumina plate has excellent insulation performance and high temperature resistance.

High Temperature Aluminum Oxide (Al2O3) Protective Tube for Engineering Advanced Fine Ceramics

Alumina oxide protective tube, also known as high temperature resistant corundum tube or thermocouple protection tube, is a ceramic tube mainly made of alumina (aluminum oxide).

1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

Looking for a tube furnace for high-temperature applications? Our 1400℃ Tube Furnace with Alumina Tube is perfect for research and industrial use.

Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

In the journey of scientific exploration and industrial production, every detail is crucial. Our arc-shaped alumina ceramic crucibles, with their excellent high temperature resistance and stable chemical properties, have become a powerful assistant in laboratories and industrial fields. They are made of high-purity alumina materials and manufactured through precision processes to ensure excellent performance in extreme environments.

1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

Looking for a high-temperature tube furnace? Check out our 1700℃ Tube Furnace with Alumina Tube. Perfect for research and industrial applications up to 1700C.

High Quality Alumina Ceramic Screw for Engineering Advanced Fine Ceramics with High Temperature Resistance and Insulation

Alumina ceramic screws are fastening components made of 99.5% alumina, ideal for extreme applications requiring excellent thermal resistance, electrical insulation and chemical resistance.

Advanced Engineering Fine Ceramics Alumina Ceramic Saggar for Fine Corundum

Alumina sagger products have the characteristics of high temperature resistance, good thermal shock stability, small expansion coefficient, anti-stripping, and good anti-powdering performance.

High Purity Alumina Granulated Powder for Engineering Advanced Fine Ceramics

Ordinary alumina granulated powder is alumina particles prepared by traditional processes, with a wide range of applications and good market adaptability. This material is known for its high purity, excellent thermal stability and chemical stability, and is suitable for a variety of high-temperature and conventional applications.

Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

Alumina ceramic crucibles are used in some materials and metal melting tools, and flat-bottomed crucibles are suitable for melting and processing larger batches of materials with better stability and uniformity.

Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

Cylindrical Crucibles Cylindrical crucibles are one of the most common crucible shapes, suitable for melting and processing a wide variety of materials, and are easy to handle and clean.

Custom-Made Alumina Zirconia Special-Shaped Ceramic Plates for Engineering Advanced Fine Ceramics Processing

Alumina ceramics have good electrical conductivity, mechanical strength and high temperature resistance, while zirconia ceramics are known for their high strength and high toughness and are widely used.

Advanced Engineering Fine Ceramics Boron Nitride (BN) Ceramic Parts

Boron nitride ((BN) is a compound with high melting point, high hardness, high thermal conductivity and high electrical resistivity. Its crystal structure is similar to graphene and harder than diamond.

Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

Zirconia insulating ceramic gasket has high melting point, high resistivity, low thermal expansion coefficient and other properties, making it an important high temperature resistant material, ceramic insulating material and ceramic sunscreen material.

High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

KT-MD High temperature debinding and pre-sintering furnace for ceramic materials with various molding processes. Ideal for electronic components such as MLCC and NFC.

Engineering Advanced Fine Ceramics Aluminium Oxide Al2O3 Ceramic Washer for Wear-Resistant Applications

Alumina wear-resistant ceramic washer are used for heat dissipation, which can replace aluminum heat sinks, with high temperature resistance and high thermal conductivity.

Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

Silicon carbide (sic) ceramic sheet is composed of high-purity silicon carbide and ultra-fine powder, which is formed by vibration molding and high-temperature sintering.

Multi Heating Zones CVD Tube Furnace Machine Chemical Vapor Deposition Chamber System Equipment

KT-CTF14 Multi Heating Zones CVD Furnace - Precise Temperature Control and Gas Flow for Advanced Applications. Max temp up to 1200℃, 4 channels MFC mass flow meter, and 7" TFT touch screen controller.

Horizontal High Temperature Graphite Vacuum Graphitization Furnace

Horizontal Graphitization Furnace: This type of furnace is designed with the heating elements placed horizontally, allowing for uniform heating of the sample. It's well-suited for graphitizing large or bulky samples that require precise temperature control and uniformity.

Ultra-High Temperature Graphite Vacuum Graphitization Furnace

The ultra-high temperature graphitization furnace utilizes medium frequency induction heating in a vacuum or inert gas environment. The induction coil generates an alternating magnetic field, inducing eddy currents in the graphite crucible, which heats up and radiates heat to the workpiece, bringing it to the desired temperature. This furnace is primarily used for graphitization and sintering of carbon materials, carbon fiber materials, and other composite materials.

Related Articles

Why Your Ceramic Furnace Tubes Keep Cracking—And How to Choose the Right One

Tired of failed experiments from cracked ceramic tubes? Learn the real reason it happens and how to select the correct material (Alumina, Quartz) for your lab.

The Ceramic Paradox: Why the Best Way to Clean an Alumina Tube is Not to Clean It

Deep cleaning is often a symptom of process failure. Discover the engineering protocols to maintain alumina tubes, prevent thermal shock, and ensure longevity.

Exploring the Key Characteristics of Tube Heating Furnaces

A tube heating furnace is a specialized type of industrial furnace that is used in various industries to heat substances through the use of fuel combustion.

Dos and don'ts during the installation of molybdenum disilicide (MoSi2) heating element

Precautions when installing MoSi2 heating elements

Cracked Tubes, Contaminated Samples? Your Furnace Tube Is The Hidden Culprit

Frustrated by failed experiments? Learn why your furnace tube material—not your process settings—is the critical variable causing inconsistent results.

Installation of Tube Furnace Fitting Tee

Mainly introduces the installation method of tube furnace fitting tee.

Ultimate Guide to High Pressure Tube Furnaces: Applications, Types, and Benefits

Explore the comprehensive guide to high pressure tube furnaces, including their applications in materials science, types such as horizontal and vertical, and key benefits for precise high-temperature processes.

Entropy and the Alumina Tube: The Art of Precision Maintenance

Discover the disciplined approach to cleaning alumina furnace tubes. Learn how to prevent thermal shock, remove residue with acid, and extend equipment life.

Molybdenum Vacuum Furnace: High-Temperature Sintering and Heat Treatment

Explore the advanced features and applications of molybdenum vacuum furnaces in high-temperature sintering and heat treatment. Learn about their construction, control systems, and maintenance tips.

Rotary Furnaces: Advanced Materials Processing and Applications

Rotary furnaces are versatile and efficient thermal processing systems used in various industries. This comprehensive guide explores the basics of rotary furnaces, their applications, advantages, and key components. Discover how rotary furnaces contribute to advanced materials processing and enhance productivity.

High Pressure Tube Furnace: Applications, Safety, and Maintenance

Explore the advanced applications, safety measures, and maintenance tips for high pressure tube furnaces. Learn how these furnaces are used in various high-temperature processes and ensure optimal performance and safety.

Vacuum Induction Melting Furnace vs Arc Melting Furnace: Choosing the Right Equipment for Your Process

Learn about the key differences between vacuum induction melting furnaces and arc melting furnaces, including their advantages and applications, to help you choose the best equipment for your specific needs.