fine ceramics

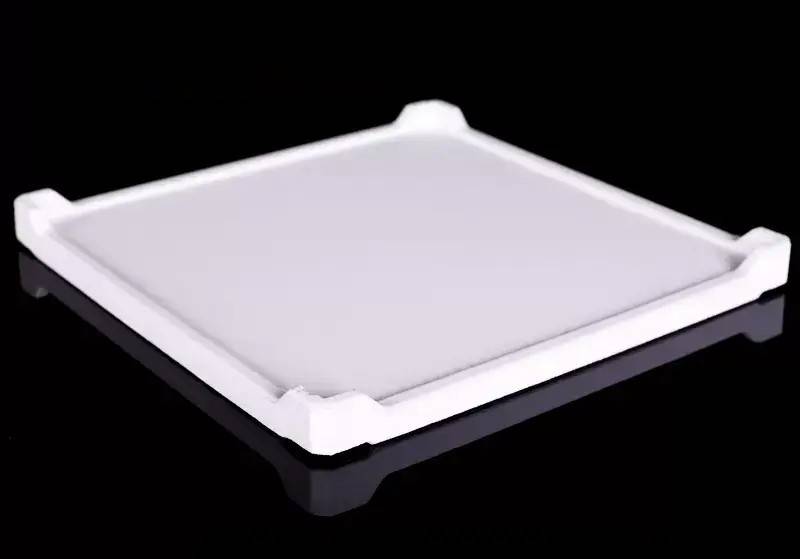

Advanced Engineering Fine Ceramics Alumina Ceramic Saggar for Fine Corundum

Item Number : KM-C05

Price varies based on specs and customizations

- Material

- Aluminum oxide

- Specification

- See the form

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Application

Fine corundum alumina sagger, also known as the ceramic setter, is an essential tool for transporting and carrying the fired ceramic body in the ceramic kiln. These plates are made of high-purity corundum and mullite as the main raw materials. By combining the excellent properties of the two materials, a high temperature composite backing plate was created that offers numerous advantages and features for ceramic kiln operations. In this article, we will explore the advantages and functions of fine corundum plates in more detail.

- The carrier of fired ceramics: the main function of the fine corundum plate is to serve as the carrier, heat preservation and transportation of fired ceramics. These plates facilitate uniform heating of ceramic products, thereby increasing heat transfer rates and energy efficiency.

- Ultra-high temperature applications: In ultra-high temperature electric kilns and electric furnaces, fine corundum plates are commonly used as push plates, bearing plates, and sagger plates. Their ability to withstand extreme temperatures makes them suitable for such applications.

- High-temperature sintering of industrial ceramics: This plate is suitable for the pollution-free high-temperature sintering process of industrial ceramics. They are used in the sintering of magnetic materials, powder metallurgy, ceramic substrates and zirconia ceramics, ensuring reliable and controlled sintering conditions.

- Sintering of electronic components: Fine corundum plates are also used for sintering of electronic components such as MLCC (multilayer ceramic capacitors), LTCC (low temperature co-fired ceramics), PTC (positive temperature coefficient) chip resistors, and capacitors. These plates provide the right environment for the precise sintering of these components, ensuring their quality and functionality.

- These plates act as a carrier for fired ceramics, improving heat transfer, energy efficiency and firing speed. They are also used in ultra-high temperature applications, sintering of technical ceramics and sintering of electronic components. use of thin rope.

Detail & Parts

| fine striped sagger | 100x100x13mm95 | 105x105x12mm99 |

| fine striped sagger | 103x103x22mm | 118x100x19mm |

| fine striped sagger | 120x120x40mm | 195x100x32mm |

| Fine corundum burning table | 100x100x15mm95 aluminum oxide - notched | 105x105x12mm99 aluminum oxide - notched |

| Fine corundum burning table | 250*250mm |

The crucibles we show are available in different sizes and custom sizes are available on request.

Advantages

- High operating temperature: This high temperature resistance ensures their reliability and stability during sintering.

- Excellent Thermal Shock Stability: They can withstand rapid temperature changes without cracking or fracturing.

- Low coefficient of expansion: ensures dimensional stability and prevents warping or deformation of fired ceramic products.

- High Bending Strength: This strength ensures the durability and longevity of the mounting plate.

- Ideal softening properties under high temperature loads: fine corundum sheets retain their structural integrity and retain their shape even under high temperature loads. This feature allows for consistent and reliable performance throughout the firing process.

- Long service life: The fine corundum plate has a long comprehensive service life. This longevity reduces the need for frequent replacements, resulting in cost savings for the kiln operator.

In summary, the fine corundum plate has the advantages of high working temperature, good thermal shock stability, low expansion coefficient, high bending strength, ideal high temperature load softening performance, and long service life.

Trusted by Industry Leaders

FAQ

What Are Advanced Ceramics?

What Are Engineering Ceramics?

What Are The Main Applications Of Fine Ceramics?

What Are The Main Types Of Advanced Ceramics?

What Are The Main Types Of Engineering Ceramics?

What Are The Main Types Of Fine Ceramics?

What Are The Applications Of Advanced Ceramics?

What Are The Applications Of Engineering Ceramics?

What Is The Principle Behind Fine Ceramics?

How Are Advanced Ceramics Manufactured?

How Do Engineering Ceramics Differ From Traditional Ceramics?

What Are The Advantages Of Using Fine Ceramics?

What Are The Advantages Of Using Advanced Ceramics?

What Are The Advantages Of Using Alumina Ceramics?

What Is The Difference Between Alumina And Zirconia Ceramics?

Why Are Zirconia Ceramics Preferred In Certain Applications?

Why Are Silicon Carbide Ceramics Used In High-temperature Applications?

What Makes Silicon Carbide Ceramics Suitable For High-temperature Applications?

What Makes Boron Nitride Ceramics Unique?

How Are Boron Nitride Ceramics Used In Electronics?

How Do Advanced Ceramics Contribute To Energy Efficiency?

What Is The Manufacturing Process Of Engineering Ceramics?

Can Engineering Ceramics Be Customized For Specific Applications?

4.8 / 5

The Alumina Ceramic Saggar has exceeded my expectations. Its exceptional quality and durability make it an indispensable tool for our ceramic kiln operations.

4.9 / 5

I highly recommend the Alumina Ceramic Saggar. Its high operating temperature and excellent thermal shock stability have significantly improved our sintering process.

4.7 / 5

The Fine Corundum Burning Table has been a game-changer for our electronic component sintering. Its precise temperature control ensures consistent and reliable results.

4.8 / 5

The long service life of the Fine Corundum Plate has saved us both time and money. Its durability is truly impressive.

4.9 / 5

The Alumina Ceramic Saggar has revolutionized our ceramic kiln operations. Its ability to withstand rapid temperature changes has minimized defects and improved product quality.

4.7 / 5

The Fine Corundum Plate's high bending strength ensures the longevity of our kiln operations. It's a reliable and durable investment.

4.8 / 5

The Alumina Ceramic Saggar's low coefficient of expansion has significantly reduced warping and deformation of our fired ceramic products. It's a valuable addition to our kiln.

4.9 / 5

The Fine Corundum Burning Table's ideal softening properties under high temperature loads have improved the consistency and reliability of our sintering process.

4.7 / 5

The Alumina Ceramic Saggar's high-purity and high-temperature characteristics have taken our ceramic kiln operations to the next level.

4.8 / 5

The Fine Corundum Plate's excellent thermal shock stability has eliminated cracking and fracturing during temperature changes. It's a game-changer for our sintering process.

4.9 / 5

The long service life of the Fine Corundum Plate has saved us both time and money. It's a cost-effective and reliable solution for our kiln operations.

4.7 / 5

The Alumina Ceramic Saggar's high operating temperature ensures the reliability and stability of our sintering process. It's a crucial tool for our ceramic kiln operations.

4.8 / 5

The Fine Corundum Burning Table's precise temperature control has improved the quality and consistency of our electronic components. It's a valuable addition to our manufacturing process.

4.9 / 5

The Fine Corundum Plate's bending strength ensures the longevity of our kiln operations. It's a durable and reliable investment.

4.7 / 5

The Alumina Ceramic Saggar's low coefficient of expansion has significantly reduced warping and deformation of our fired ceramic products. It's a valuable addition to our kiln.

4.8 / 5

The Fine Corundum Burning Table's ideal softening properties under high temperature loads have improved the consistency and reliability of our sintering process.

4.9 / 5

The Alumina Ceramic Saggar's high-purity and high-temperature characteristics have taken our ceramic kiln operations to the next level.

4.7 / 5

The Fine Corundum Plate's excellent thermal shock stability has eliminated cracking and fracturing during temperature changes. It's a game-changer for our sintering process.

4.8 / 5

The long service life of the Fine Corundum Plate has saved us both time and money. It's a cost-effective and reliable solution for our kiln operations.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

High Quality Alumina Ceramic Screw for Engineering Advanced Fine Ceramics with High Temperature Resistance and Insulation

Alumina ceramic screws are fastening components made of 99.5% alumina, ideal for extreme applications requiring excellent thermal resistance, electrical insulation and chemical resistance.

Custom-Made Alumina Zirconia Special-Shaped Ceramic Plates for Engineering Advanced Fine Ceramics Processing

Alumina ceramics have good electrical conductivity, mechanical strength and high temperature resistance, while zirconia ceramics are known for their high strength and high toughness and are widely used.

High Purity Alumina Granulated Powder for Engineering Advanced Fine Ceramics

Ordinary alumina granulated powder is alumina particles prepared by traditional processes, with a wide range of applications and good market adaptability. This material is known for its high purity, excellent thermal stability and chemical stability, and is suitable for a variety of high-temperature and conventional applications.

High Temperature Alumina (Al2O3) Furnace Tube for Engineering Advanced Fine Ceramics

High temperature alumina furnace tube combines the advantages of high hardness of alumina, good chemical inertness and steel, and has excellent wear resistance, thermal shock resistance and mechanical shock resistance.

High Temperature Wear-Resistant Alumina Al2O3 Plate for Engineering Advanced Fine Ceramics

High temperature wear-resistant insulating alumina plate has excellent insulation performance and high temperature resistance.

Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

In the journey of scientific exploration and industrial production, every detail is crucial. Our arc-shaped alumina ceramic crucibles, with their excellent high temperature resistance and stable chemical properties, have become a powerful assistant in laboratories and industrial fields. They are made of high-purity alumina materials and manufactured through precision processes to ensure excellent performance in extreme environments.

Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

zirconia ceramic ball have the characteristics of high strength, high hardness, PPM wear level, high fracture toughness, good wear resistance, and high specific gravity.

Advanced Engineering Fine Ceramics Low Temperature Alumina Granulation Powder

Low temperature alumina granulation powder is a kind of alumina particles produced by a special low temperature process, designed to meet the needs of temperature sensitive applications. This material has excellent low temperature performance and good processing characteristics, suitable for a variety of industries that require low temperature processing and treatment.

Advanced Engineering Fine Ceramics Aluminum Nitride (AlN) Ceramic Sheet

Aluminum nitride (AlN) has the characteristics of good compatibility with silicon. It is not only used as a sintering aid or reinforcing phase for structural ceramics, but its performance far exceeds that of alumina.

Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

Silicon carbide (sic) ceramic sheet is composed of high-purity silicon carbide and ultra-fine powder, which is formed by vibration molding and high-temperature sintering.

Engineering Advanced Fine Ceramics Aluminium Oxide Al2O3 Ceramic Washer for Wear-Resistant Applications

Alumina wear-resistant ceramic washer are used for heat dissipation, which can replace aluminum heat sinks, with high temperature resistance and high thermal conductivity.

Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

Alumina ceramic crucibles are used in some materials and metal melting tools, and flat-bottomed crucibles are suitable for melting and processing larger batches of materials with better stability and uniformity.

Precision Machined Yttria Stabilized Zirconia Ceramic Plate for Engineering Advanced Fine Ceramics

Yttrium-stabilized zirconia has the characteristics of high hardness and high temperature resistance, and has become an important material in the field of refractories and special ceramics.

High Temperature Aluminum Oxide (Al2O3) Protective Tube for Engineering Advanced Fine Ceramics

Alumina oxide protective tube, also known as high temperature resistant corundum tube or thermocouple protection tube, is a ceramic tube mainly made of alumina (aluminum oxide).

Precision Machined Yttrium Stabilized Zirconia Ceramic Rod for Engineering Advanced Fine Ceramics

Zirconia ceramic rods are prepared by isostatic pressing, and a uniform, dense and smooth ceramic layer and transition layer are formed at high temperature and high speed.

Silicon Carbide (SIC) Ceramic Plate for Engineering Advanced Fine Ceramics

Silicon nitride (sic) ceramic is an inorganic material ceramic that does not shrink during sintering. It is a high-strength, low-density, high-temperature-resistant covalent bond compound.

Precision Machined Silicon Nitride (SiN) Ceramic Sheet for Engineering Advanced Fine Ceramics

Silicon nitride plate is a commonly used ceramic material in the metallurgical industry due to its uniform performance at high temperatures.

Advanced Engineering Fine Ceramics Boron Nitride (BN) Ceramic Parts

Boron nitride ((BN) is a compound with high melting point, high hardness, high thermal conductivity and high electrical resistivity. Its crystal structure is similar to graphene and harder than diamond.

Silicon Carbide (SIC) Ceramic Sheet Flat Corrugated Heat Sink for Engineering Advanced Fine Ceramics

Silicon carbide (sic) ceramic heat sink not only does not generate electromagnetic waves, but also can isolate electromagnetic waves and absorb part of electromagnetic waves.

Related Articles

Dos and don'ts during the installation of molybdenum disilicide (MoSi2) heating element

Precautions when installing MoSi2 heating elements

Ceramic Alumina Crucible for Thermal Analysis Test Containers

An in-depth guide on selecting and using ceramic alumina crucibles for thermal analysis tests, focusing on factors affecting test results.

Alumina Crucibles in Precision Casting

Explores the use of alumina crucibles in precision casting, focusing on their properties and advantages in high-temperature alloy melting.

Advantages of Mullite Fiber Lining for High-Temperature Furnaces

Explores the benefits of mullite fiber linings in high-temperature industrial furnaces, focusing on thermal stability, energy efficiency, and long-term cost savings.

Precision Ceramics in Semiconductor Applications

Exploring the use of precision ceramics in semiconductor equipment, their properties, and manufacturing processes.

In-Depth Understanding of Zirconia Sintering Furnaces

An exploration of zirconia sintering processes, furnace components, and optimal conditions for achieving high-quality dental restorations.

Substances Suitable for Calcination in a High-Temperature Muffle Furnace

An overview of materials and experiments suitable for calcination in a high-temperature muffle furnace.

Preparation and Performance of Alumina Crucibles for Vacuum Induction Melting Furnace

This article discusses the preparation process and performance benefits of alumina crucibles for vacuum induction melting furnaces, emphasizing thermal stability and long service life.

Precision Ceramic Materials for Energy Conversion Applications

Overview of various ceramic materials used in energy conversion technologies, including heaters, piezoelectric ceramics, and solid oxide fuel cells.

Comprehensive Guide to Alumina Crucibles in Powder Metallurgy

An in-depth look at the properties, applications, and usage of alumina crucibles in powder metallurgy processes.

Mechanical Properties and Structural Enhancements of Ceramics

An in-depth analysis of the mechanical properties of ceramics, including strengths, weaknesses, and methods for improvement.

Defects and Solutions for Isostatically Pressed Ceramic Balls

This article discusses various defects in isostatically pressed ceramic balls and provides solution strategies for each type of defect.