fine ceramics

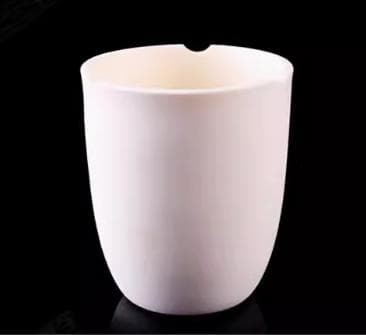

Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

Item Number : KM-C016

Price varies based on specs and customizations

- Material

- 99% Alumina

- Specification

- See the form

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Introduction

The arc-shaped alumina ceramic crucible is renowned for its high-temperature resistance and durability, primarily used in industrial applications for melting and processing metals like stainless steel and nickel alloys. Made from high-purity aluminum oxide (Al2O3 > 99%), this crucible exhibits excellent thermal conductivity and shock resistance, capable of withstanding temperatures up to 1800°C for short-term use. Its robust acid and alkali resistance makes it ideal for handling various chemical compounds, excluding alkaline substances and hydrofluoric acid. Despite its high cost, the crucible's superior mechanical strength and insulation properties make it a preferred choice in high-temperature industrial processes.

Applications

Arc-shaped alumina ceramic crucibles are highly specialized containers designed for high-temperature applications, particularly in environments where resistance to thermal shock and chemical inertness are critical. These crucibles are ideal for a variety of industrial and laboratory processes where maintaining the integrity of the sample or material is paramount.

- Metallurgical Industry: Used for melting and alloying metals, especially in the production of stainless steel and nickel alloys.

- Ceramic Manufacturing: Suitable for high-temperature sintering and firing of ceramic materials.

- Chemical Processing: Employed in reactions involving acidic substances, such as K2S2O7, where resistance to corrosion is necessary.

- Research and Development: Used in laboratories for experiments requiring high-temperature stability and inertness to various atmospheres.

- Glass Industry: Can be used in the production of specialty glasses that require high-temperature processing.

- Refractory Applications: Used in environments where high-temperature insulation properties and mechanical strength are required.

These crucibles are particularly noted for their ability to operate in both oxidizing and reducing atmospheres up to temperatures of 1750°C, making them versatile tools in high-temperature applications.

Features

Alumina ceramic crucibles are renowned for their exceptional high-temperature resistance and chemical stability, making them ideal for various high-temperature applications in laboratory and industrial settings. These crucibles offer several key benefits that enhance their utility and efficiency in handling demanding processes.

- Metallurgical Industry: Used for melting and alloying metals, especially in the production of stainless steel and nickel alloys.

- Ceramic Manufacturing: Suitable for high-temperature sintering and firing of ceramic materials.

- Chemical Processing: Employed in reactions involving acidic substances, such as K2S2O7, where resistance to corrosion is necessary.

- Research and Development: Used in laboratories for experiments requiring high-temperature stability and inertness to various atmospheres.

- Glass Industry: Can be used in the production of specialty glasses that require high-temperature processing.

- Refractory Applications: Used in environments where high-temperature insulation properties and mechanical strength are required.

These features collectively make the arc-shaped alumina ceramic crucible a robust and reliable choice for high-temperature applications, particularly in industries and laboratories where precision and material purity are critical.

Details & Parts

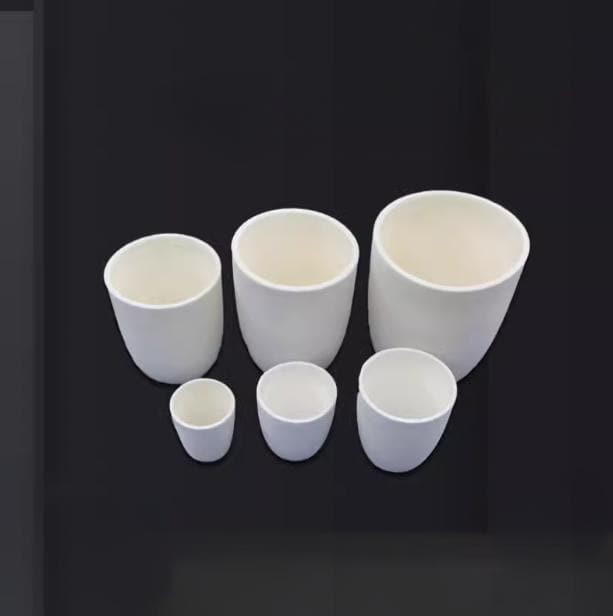

Regular

Thickened and heightened

Funnel type

With window

Technical specifications

Ordinary:

| Model | Upper diameter(mm) | Bottom diameter(mm) | Wall thickness(mm) | Height(mm) |

|---|---|---|---|---|

| 3ml | 20 | 17 | 1.5 | 16 |

| 4ml | 25 | 19 | 1.5 | 18 |

| 5ml | 25 | 17 | 1.5 | 21 |

| 10ml | 30 | 21 | 2 | 28 |

| 15ml | 36 | 21 | 2 | 28 |

| 20ml | 38 | 24 | 2.5 | 34 |

| 25ml | 39 | 25 | 2.5 | 39 |

| 30ml | 45 | 27 | 2.5 | 40 |

| 40ml | 45 | 30 | 3 | 46 |

| 50ml | 50 | 32 | 3 | 49 |

| 100ml | 62 | 36 | 3 | 60 |

| 150ml | 75 | 45 | 3 | 70 |

| 300ml | 100 | 50 | 5 | 85 |

Thickened/heightened:

| Model | Upper diameter(mm) | Bottom diameter(mm) | Wall thickness(mm) | Height(mm) |

|---|---|---|---|---|

| 10ml | 28 | 19 | 2 | 33 |

| 15ml | 34 | 22 | 2 | 33 |

| 20ml | 35 | 24 | 2.5 | 40 |

| 30ml | 39 | 25 | 2.5 | 48 |

| 50ml | 50 | 30 | 3 | 63 |

| 100ml | 58 | 36 | 3 | 70 |

| 150ml | 66 | 40 | 4 | 76 |

| 200ml | 70 | 47 | 4 | 88 |

| 300ml | 83 | 50 | 4 | 106 |

| 460ml | 85 | 55 | 4 | 130 |

| 500ml | 100 | 62 | 4.5 | 116 |

| 700ml | 111 | 75 | 6 | 128 |

| 1000ml | 120 | 80 | 6 | 150 |

| 1300ml | 130 | 85 | 5 | 155 |

| 1500ml | 140 | 85 | 5 | 175 |

| 2300ml | 165 | 110 | 5 | 153 |

| 3500ml | 220 | 120 | 8 | 150 |

Advantages

- Exceptional High-Temperature Performance: The 85% alumina ceramic crucible can operate under a reduction-oxidation atmosphere at temperatures ranging from 1290℃ to 1350℃, showcasing its superior high-temperature insulation properties and mechanical strength. This makes it ideal for long-term use in stable environments with minimal temperature fluctuations.

- Superior Thermal Conductivity and Low Thermal Expansion: With a large thermal conductivity and low thermal expansion, this crucible ensures efficient heat distribution and minimal risk of thermal shock, enhancing its durability and reliability in high-temperature applications.

- High Purity and Chemical Resistance: The crucible boasts an Al2O3 content greater than 99%, providing excellent chemical resistance and stability against acid and alkali erosion, making it suitable for handling a wide range of reactive materials.

- Resistance to Rapid Heat and Cold: The alumina ceramic material is designed to withstand rapid temperature changes without cracking or bursting, ensuring safety and longevity even under fluctuating thermal conditions.

- Long-Term and Short-Term Temperature Tolerance: Capable of long-term use at 1600℃ and short-term use up to 1800℃, this crucible is versatile and can handle extreme temperature demands, making it a robust choice for various high-temperature processes.

- Anti-Oxidation Treatment: Special anti-oxidation treatments extend the crucible's service life by protecting it from oxidative degradation, ensuring consistent performance over extended periods.

- Special Technology for Enhanced Durability: The use of special production technologies results in high bulk density and low porosity, which resist the erosion of molten aluminum and its gas particles, maintaining the crucible's integrity and effectiveness.

Designed for You

KinTek provide deep custom made service and equipment to worldwide customers, our specialized teamwork and rich experienced engineers are capable to undertake the custom tailoring hardware and software equipment requirements, and help our customer to build up the exclusive and personalized equipment and solution!

Would you please drop your ideas to us, our engineers are ready for you now!

Trusted by Industry Leaders

FAQ

What Are Advanced Ceramics?

What Are The Main Applications Of Fine Ceramics?

What Are Engineering Ceramics?

What Are The Main Benefits Of Using An Arc-shaped Alumina Ceramic Crucible?

What Are The High-temperature Properties Of A 99% Alumina Ceramic Crucible?

How Should I Handle The Heating And Cooling Of An Alumina Ceramic Crucible?

What Are The Main Types Of Advanced Ceramics?

What Are The Common Applications Of Alumina Crucibles?

What Are The Main Types Of Fine Ceramics?

What Are The Advantages Of Using Ceramic Crucibles?

What Are The Main Types Of Engineering Ceramics?

What Are The Applications Of Advanced Ceramics?

What Are The Advantages Of Using Alumina Crucibles?

What Is The Principle Behind Fine Ceramics?

What Are Some Common Uses Of Ceramic Crucibles?

What Are The Applications Of Engineering Ceramics?

How Are Advanced Ceramics Manufactured?

How Should Alumina Crucibles Be Handled And Maintained?

What Are The Advantages Of Using Fine Ceramics?

How Can I Choose The Right Ceramic Crucible For My Application?

How Do Engineering Ceramics Differ From Traditional Ceramics?

What Are The Advantages Of Using Advanced Ceramics?

How Should Ceramic Crucibles Be Handled And Maintained?

What Are The Advantages Of Using Alumina Ceramics?

What Is The Difference Between Alumina And Zirconia Ceramics?

Why Are Zirconia Ceramics Preferred In Certain Applications?

Why Are Silicon Carbide Ceramics Used In High-temperature Applications?

What Makes Silicon Carbide Ceramics Suitable For High-temperature Applications?

What Makes Boron Nitride Ceramics Unique?

How Are Boron Nitride Ceramics Used In Electronics?

How Do Advanced Ceramics Contribute To Energy Efficiency?

What Is The Manufacturing Process Of Engineering Ceramics?

Can Engineering Ceramics Be Customized For Specific Applications?

4.7 / 5

Outstanding thermal resistance, perfect for our high-temp experiments.

4.8 / 5

Excellent value for money, durable and efficient.

4.9 / 5

Fast delivery and the quality exceeded my expectations.

4.7 / 5

Highly recommend for any lab needing reliable crucibles.

4.8 / 5

Sturdy construction, ideal for long-term high-temp use.

4.9 / 5

Great product, handles extreme temperatures with ease.

4.7 / 5

Impressive thermal conductivity, saves energy in our processes.

4.8 / 5

Top-notch quality, very satisfied with the purchase.

4.9 / 5

Quick shipping, the crucible is a game-changer for our lab.

4.7 / 5

Durable and resistant to thermal shock, excellent product.

4.8 / 5

Highly resistant to chemical corrosion, very reliable.

4.9 / 5

Best crucible for high-temperature applications, highly recommend.

4.7 / 5

Efficient and cost-effective, perfect for our needs.

4.8 / 5

Superb thermal insulation properties, very pleased.

4.9 / 5

Quick and easy to use, great for frequent lab tasks.

4.7 / 5

Excellent mechanical strength, handles heavy use well.

4.8 / 5

High-quality alumina, very durable and effective.

4.9 / 5

Perfect for our high-temp experiments, no issues at all.

4.7 / 5

Great product, highly resistant to high temperatures.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

High Quality Alumina Ceramic Screw for Engineering Advanced Fine Ceramics with High Temperature Resistance and Insulation

Alumina ceramic screws are fastening components made of 99.5% alumina, ideal for extreme applications requiring excellent thermal resistance, electrical insulation and chemical resistance.

High Temperature Wear-Resistant Alumina Al2O3 Plate for Engineering Advanced Fine Ceramics

High temperature wear-resistant insulating alumina plate has excellent insulation performance and high temperature resistance.

Advanced Engineering Fine Ceramics Alumina Ceramic Saggar for Fine Corundum

Alumina sagger products have the characteristics of high temperature resistance, good thermal shock stability, small expansion coefficient, anti-stripping, and good anti-powdering performance.

Custom-Made Alumina Zirconia Special-Shaped Ceramic Plates for Engineering Advanced Fine Ceramics Processing

Alumina ceramics have good electrical conductivity, mechanical strength and high temperature resistance, while zirconia ceramics are known for their high strength and high toughness and are widely used.

Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

Cylindrical Crucibles Cylindrical crucibles are one of the most common crucible shapes, suitable for melting and processing a wide variety of materials, and are easy to handle and clean.

High Temperature Alumina (Al2O3) Furnace Tube for Engineering Advanced Fine Ceramics

High temperature alumina furnace tube combines the advantages of high hardness of alumina, good chemical inertness and steel, and has excellent wear resistance, thermal shock resistance and mechanical shock resistance.

Advanced Engineering Fine Ceramics Boron Nitride (BN) Ceramic Parts

Boron nitride ((BN) is a compound with high melting point, high hardness, high thermal conductivity and high electrical resistivity. Its crystal structure is similar to graphene and harder than diamond.

High Purity Alumina Granulated Powder for Engineering Advanced Fine Ceramics

Ordinary alumina granulated powder is alumina particles prepared by traditional processes, with a wide range of applications and good market adaptability. This material is known for its high purity, excellent thermal stability and chemical stability, and is suitable for a variety of high-temperature and conventional applications.

Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

Zirconia insulating ceramic gasket has high melting point, high resistivity, low thermal expansion coefficient and other properties, making it an important high temperature resistant material, ceramic insulating material and ceramic sunscreen material.

High Temperature Aluminum Oxide (Al2O3) Protective Tube for Engineering Advanced Fine Ceramics

Alumina oxide protective tube, also known as high temperature resistant corundum tube or thermocouple protection tube, is a ceramic tube mainly made of alumina (aluminum oxide).

Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

Silicon carbide (sic) ceramic sheet is composed of high-purity silicon carbide and ultra-fine powder, which is formed by vibration molding and high-temperature sintering.

Engineering Advanced Fine Ceramics Aluminium Oxide Al2O3 Ceramic Washer for Wear-Resistant Applications

Alumina wear-resistant ceramic washer are used for heat dissipation, which can replace aluminum heat sinks, with high temperature resistance and high thermal conductivity.

Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

Alumina ceramic crucibles are used in some materials and metal melting tools, and flat-bottomed crucibles are suitable for melting and processing larger batches of materials with better stability and uniformity.

Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

zirconia ceramic ball have the characteristics of high strength, high hardness, PPM wear level, high fracture toughness, good wear resistance, and high specific gravity.

Electron Beam Evaporation Coating Tungsten Crucible and Molybdenum Crucible for High Temperature Applications

Tungsten and molybdenum crucibles are commonly used in electron beam evaporation processes due to their excellent thermal and mechanical properties.

Precision Machined Silicon Nitride (SiN) Ceramic Sheet for Engineering Advanced Fine Ceramics

Silicon nitride plate is a commonly used ceramic material in the metallurgical industry due to its uniform performance at high temperatures.

Precision Machined Yttria Stabilized Zirconia Ceramic Plate for Engineering Advanced Fine Ceramics

Yttrium-stabilized zirconia has the characteristics of high hardness and high temperature resistance, and has become an important material in the field of refractories and special ceramics.

Silicon Carbide (SIC) Ceramic Plate for Engineering Advanced Fine Ceramics

Silicon nitride (sic) ceramic is an inorganic material ceramic that does not shrink during sintering. It is a high-strength, low-density, high-temperature-resistant covalent bond compound.

Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

High-purity and smooth conductive boron nitride crucible for electron beam evaporation coating, with high temperature and thermal cycling performance.

Related Articles

Introduction to Various Ceramic Crucibles

An overview of different types of ceramic crucibles, their properties, and applications.

Ceramic Alumina Crucible for Thermal Analysis Test Containers

An in-depth guide on selecting and using ceramic alumina crucibles for thermal analysis tests, focusing on factors affecting test results.

Alumina Crucibles in Precision Casting

Explores the use of alumina crucibles in precision casting, focusing on their properties and advantages in high-temperature alloy melting.

Guidelines for the Use of Boron Nitride Crucibles

Instructions on the proper use, precautions, and compatibility of boron nitride crucibles.

Comparison of Pyrolytic Graphite and Pyrolytic Boron Nitride Crucibles

A detailed comparison of pyrolytic graphite and pyrolytic boron nitride crucibles, focusing on their preparation processes, characteristics, and applications.

Advanced Alumina Ceramics: Applications and Manufacturing Techniques

Overview of alumina ceramics' applications and manufacturing methods, including molds, isostatic pressing, and green body formation.

Advanced Alumina Ceramics: Applications and Manufacturing Techniques

This article discusses the applications and manufacturing techniques of advanced alumina ceramics, including molds, isostatic pressing, and green bodies.

Inorganic Non-Metallic Materials: Crucibles

An overview of crucibles made from various inorganic non-metallic materials, their uses, technical parameters, and advantages.

The Role and Types of Crucibles in Scientific Experiments

Explores the significance and various types of crucibles in scientific experiments, focusing on their materials and applications.

Comprehensive Guide to Alumina Crucibles in Powder Metallurgy

An in-depth look at the properties, applications, and usage of alumina crucibles in powder metallurgy processes.

Preparation and Performance of Alumina Crucibles for Vacuum Induction Melting Furnace

This article discusses the preparation process and performance benefits of alumina crucibles for vacuum induction melting furnaces, emphasizing thermal stability and long service life.

Fused Silica Crucible: Properties, Applications, and Preparation Process

An in-depth look at the properties, applications, and preparation methods of fused silica crucibles in the solar photovoltaic industry.