Introduction to Crucibles

Historical and Modern Uses

Crucibles have played a pivotal role in the melting and refining of metals and liquids, with their historical uses tracing back to ancient civilizations. Early crucibles were crafted from materials like clay and platinum, which were chosen for their ability to withstand high temperatures and chemical reactions. These early applications were crucial in the development of metallurgy, allowing for the creation of tools, weapons, and ornaments from raw metals.

In contrast, modern techniques have expanded the range of materials used in crucibles, catering to the diverse needs of various industries. For instance, quartz ceramic crucibles, made from high-purity fused silica, are renowned for their fine structure and low thermal conductivity, making them ideal for applications in glass, metallurgy, and electronics. Similarly, corundum crucibles, composed of over 95% alumina, are known for their hardness and resistance to fusion, making them suitable for melting samples with anhydrous Na2CO3.

Moreover, advancements in material science have introduced crucibles made from boron nitride (P-BN), which excel in high-temperature insulation and thermal conductivity, and are commonly used in semiconductor processes. Zirconia crucibles, with a melting point of 2700℃, are excellent for melting precious metals like platinum and palladium, while yttrium oxide crucibles, made from Y2O3, are highly resistant to high temperatures and can be used for melting titanium and its alloys.

This evolution from traditional to modern crucible materials not only reflects technological progress but also underscores the adaptability and versatility of crucibles in scientific and industrial applications.

Importance in Chemical Reactions

Crucibles play a pivotal role in ensuring the smooth progression of chemical reactions, particularly those involving solid-liquid interactions and high-temperature processes. Their primary function is to provide stable and reliable containers that can withstand the rigorous conditions of such reactions.

One of the key advantages of using crucibles is their ability to maintain a consistent environment for the reactants. This stability is crucial for reactions where even minor fluctuations in temperature or pressure can significantly alter the outcome. For instance, in metallurgical processes, the precise control of temperature is essential for the successful melting and refining of metals. Crucibles made from materials like quartz ceramic or corundum offer excellent thermal stability, ensuring that the reaction conditions remain optimal throughout the process.

Moreover, crucibles are designed to resist chemical侵蚀, which is particularly important in reactions involving corrosive substances. Materials such as boron nitride and zirconia are known for their high resistance to chemical attack, making them ideal for use in reactions where the reactants are highly reactive or corrosive. This resistance not only protects the crucible itself but also ensures that the integrity of the reaction is maintained, preventing any contamination that could affect the purity of the final product.

In addition to their thermal and chemical stability, crucibles also facilitate efficient heat transfer, which is vital for reactions that require rapid or uniform heating. For example, in semiconductor manufacturing, boron nitride crucibles are preferred due to their excellent thermal conductivity, which helps in achieving the precise temperature control needed for the growth of high-quality semiconductor crystals.

In summary, crucibles are indispensable in chemical reactions, offering a combination of stability, resistance, and efficient heat transfer that ensures the success of complex and high-temperature processes. Their robust design and material properties make them the go-to choice for scientists and researchers across various fields, from metallurgy to semiconductor production.

Types of Ceramic Crucibles

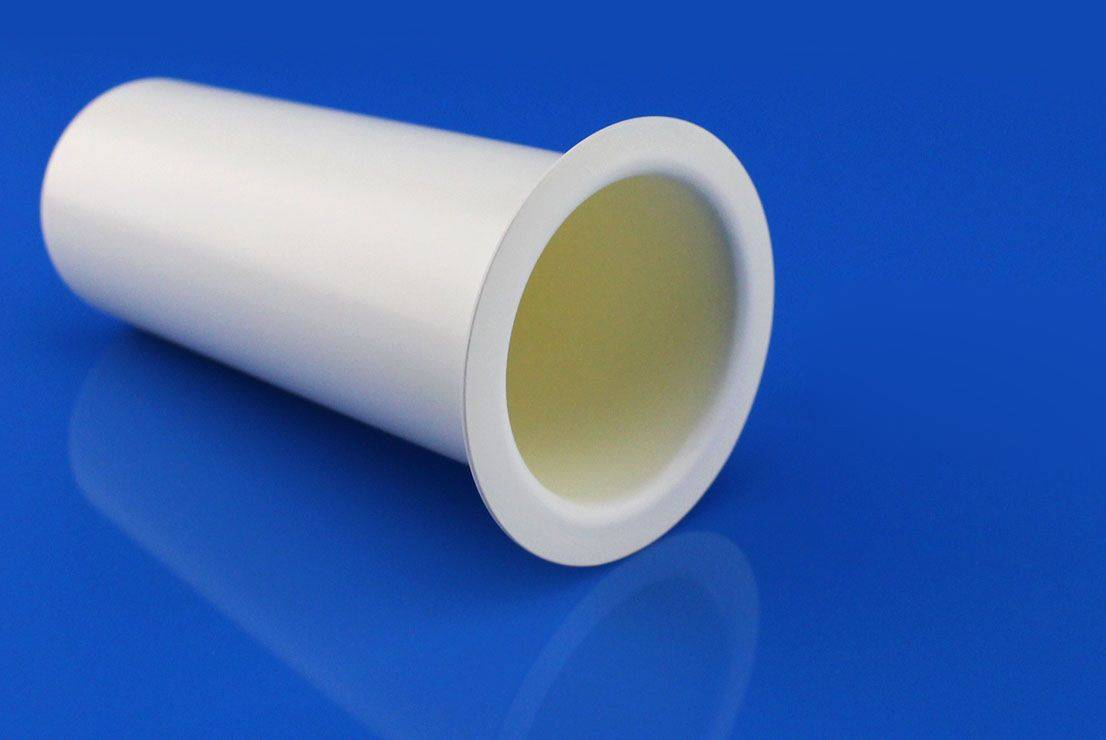

Quartz Ceramic Crucible

Quartz ceramic crucibles are crafted from high-purity fused silica, a material renowned for its exceptional purity and structural integrity. This unique composition grants the crucibles a fine, homogeneous structure, which is crucial for maintaining precise temperature control during high-temperature processes. Unlike other materials, fused silica exhibits remarkably low thermal conductivity, ensuring that heat is evenly distributed and minimizing the risk of thermal shock.

These crucibles are indispensable in a variety of industrial applications, particularly in sectors where high-purity and temperature stability are paramount. In the glass industry, quartz ceramic crucibles are used for melting and refining raw materials, ensuring the production of high-quality glass products. Similarly, in metallurgy, these crucibles facilitate the precise melting and alloying of metals, contributing to the development of advanced alloys with specific properties.

In the electronics industry, quartz ceramic crucibles play a pivotal role in the production of semiconductor materials. Their ability to withstand extreme temperatures without compromising structural integrity makes them ideal for processing high-purity silicon and other critical materials used in electronic components. This broad spectrum of applications underscores the versatility and reliability of quartz ceramic crucibles in modern industrial processes.

Corundum Crucible

Corundum crucibles are distinguished by their high alumina content, typically exceeding 95%. This composition endows them with exceptional hardness and resistance to fusion, making them ideal for high-temperature applications. One of their primary uses is in the melting of samples with anhydrous sodium carbonate (Na₂CO₃). The high alumina content ensures that the crucibles maintain their structural integrity even under extreme conditions, preventing any unwanted reactions between the crucible material and the sample.

In addition to their robustness, corundum crucibles offer excellent thermal stability. This property is crucial in scientific experiments where precise temperature control is essential. The crucibles' ability to withstand high temperatures without deforming or cracking allows for consistent and reliable results. This makes corundum crucibles a preferred choice in laboratories and industrial settings where the integrity of the experiment is paramount.

| Property | Description |

|---|---|

| Composition | More than 95% alumina |

| Hardness | Exceptionally hard, resistant to fusion |

| Application | Suitable for melting samples with anhydrous Na₂CO₃ |

| Thermal Stability | Maintains structural integrity under high temperatures, ensuring reliable results |

Boron Nitride Crucible

Boron Nitride (BN) crucibles, particularly those made from P-BN (Polycrystalline Boron Nitride), are renowned for their exceptional performance in high-temperature environments. These crucibles are not only capable of withstanding extreme temperatures in high vacuum conditions but also exhibit outstanding corrosion and electrical resistance. This unique combination of properties makes BN crucibles an ideal choice across a spectrum of industries, including crystal growth, high-temperature furnace insulation, and electric insulation in vacuum systems.

In the realm of semiconductor processes, BN crucibles are indispensable due to their superior thermal conductivity and insulation capabilities. They are typically used at temperatures ranging from approximately 1800 degrees Celsius under vacuum to around 2100 degrees Celsius under atmospheric protection, making them suitable for ultra-high temperature forging applications. The longevity of BN crucibles is further enhanced when used in nitrogen or argon atmospheres, where their thermal resistance is at its peak.

Moreover, the structural integrity of BN crucibles remains uncompromised even under rapid temperature fluctuations. For instance, a BN crucible can withstand sudden cooling from 1500 degrees Celsius without cracking. Additionally, after being held in a 1000-degree furnace for 20 minutes, the crucible can endure hundreds of continuous quenching cycles without any damage. This durability underscores the reliability and robustness of BN crucibles in demanding industrial settings.

Zirconia Crucible

Zirconia crucibles, known for their exceptional thermal stability, boast a melting point of 2700℃. This high melting point makes them particularly suitable for tasks requiring extreme heat resistance, such as melting platinum, palladium, and other precious metals. The robust nature of zirconia crucibles ensures that they can withstand the rigorous conditions typically encountered in high-temperature processes.

In addition to their high melting point, zirconia crucibles offer several other advantages. They are highly resistant to chemical corrosion, making them ideal for use in environments where other materials might degrade. This property is particularly beneficial when dealing with reactive metals and compounds. Furthermore, zirconia crucibles exhibit excellent thermal shock resistance, allowing them to endure rapid temperature changes without cracking or breaking.

The applications of zirconia crucibles extend beyond just precious metals. They are also used in various scientific and industrial processes, including high-temperature synthesis, ceramic manufacturing, and semiconductor production. Their ability to maintain structural integrity under extreme conditions makes them a versatile and indispensable tool in many fields.

Yttrium Oxide Crucible

Yttrium oxide crucibles, crafted from Y₂O₃, are renowned for their exceptional resistance to high temperatures. This attribute makes them particularly suitable for applications requiring extreme heat tolerance, such as the melting of titanium and its alloys. The stability of yttrium oxide under high-temperature conditions ensures that the crucibles remain intact and functional even in the most demanding environments.

In addition to their thermal resilience, yttrium oxide crucibles offer several other advantages. They are chemically inert, meaning they do not react with the materials they are used to melt, thereby maintaining the purity of the end product. This characteristic is crucial in industries where material integrity is paramount, such as in the production of high-performance alloys and specialized metals.

The use of yttrium oxide crucibles extends beyond just melting titanium. They are also employed in various high-temperature processes, including the synthesis of advanced ceramics and the production of optical fibers. Their versatility and reliability make them an indispensable tool in both research and industrial settings.

Related Products

- Evaporation Crucible for Organic Matter

- Boron Nitride (BN) Crucible for Phosphorous Powder Sintered

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- E Beam Crucibles Electron Gun Beam Crucible for Evaporation