Thin Film Deposition Parts

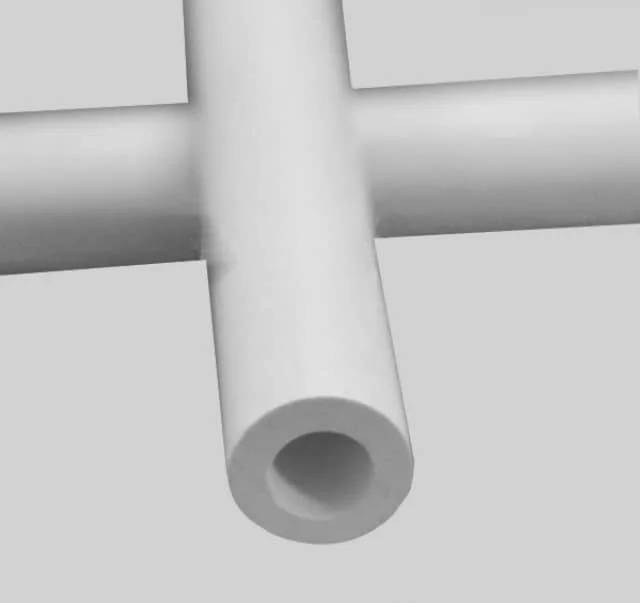

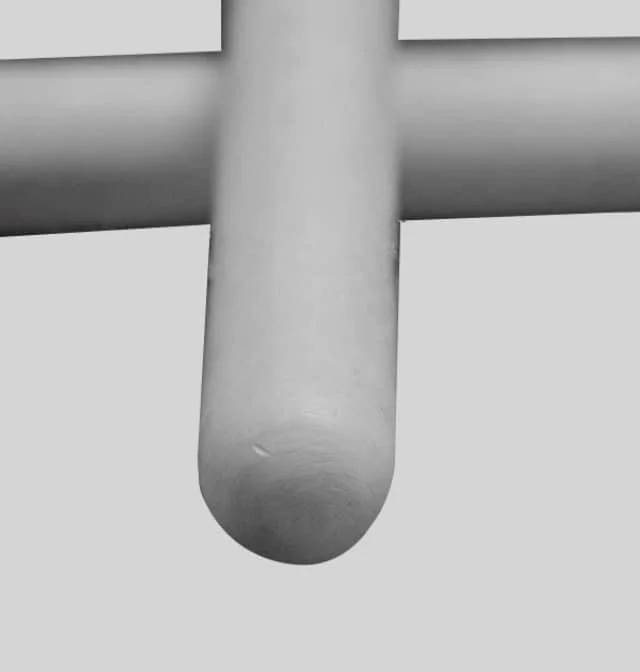

Hexagonal Boron Nitride HBN Thermocouple Protection Tube

Item Number : KM-D02

Price varies based on specs and customizations

- Material

- Boron nitride (BN)

- Specification

- 20*4*1mm

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Application

hexagonal boron nitride(HBN) thermocouple protection tubes are designed to protect thermocouple sensors from external factors that may affect their performance or life. Since boron nitride has high heat resistance, high thermal conductivity, low thermal expansion coefficient, and good corrosion resistance, the continuous measurement of the internal temperature of molten metal in the smelting industry is convenient for continuous monitoring, and avoids the rapid heating process of the corundum-based temperature measurement protective sleeve in the past. Difficulties in rupture phenomena.

- High Temperature Applications: Protect thermocouple sensors from temperature extremes, ensuring accurate temperature measurements and extending sensor life.

- Corrosive Environments: Resists chemical attack, ensures accurate temperature readings and prevents sensor damage.

- Contaminated Atmospheres: Protect thermocouples from these contaminants, ensuring accurate measurements and preventing sensor fouling or damage.

- Process Monitoring: Helps monitor and control temperature in the process to ensure product quality, process efficiency and safety.

- Research and Development: Enables accurate temperature measurement in a controlled environment, thereby facilitating research and development activities.

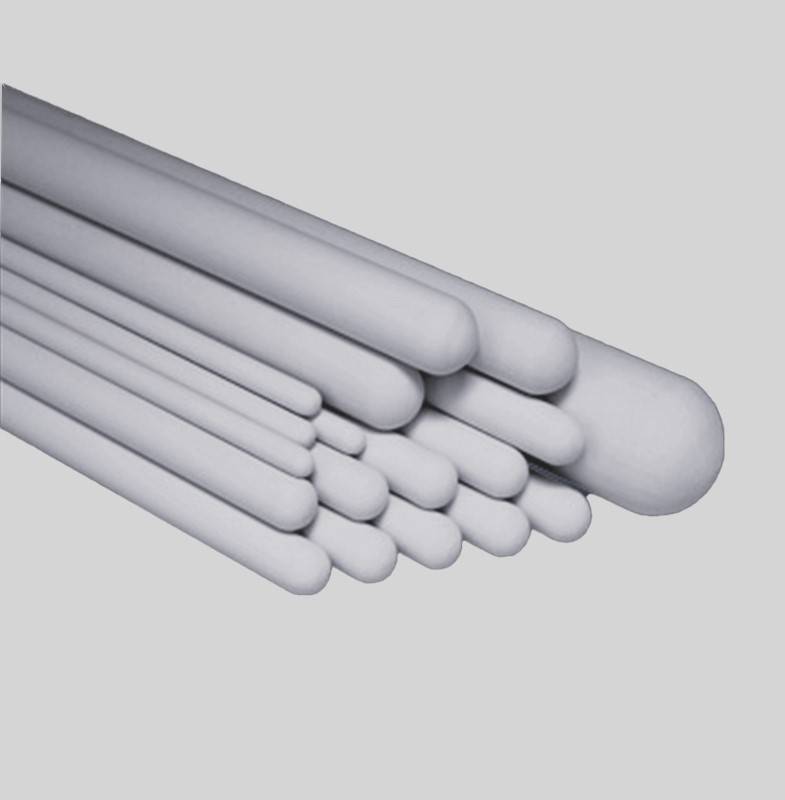

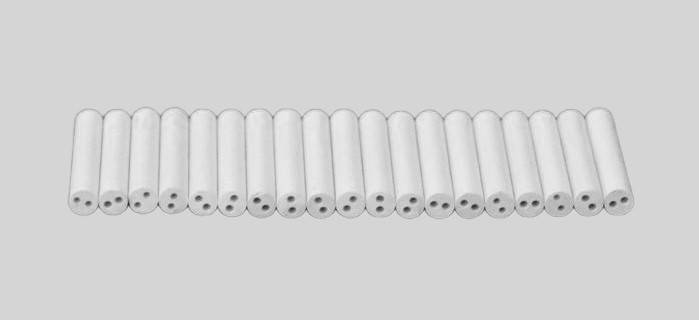

Detail & Parts

The products we display are available in different sizes and custom sizes are available upon request.

Advantages

- Material Composition: Thermocouple protection tubes are usually made of materials that are resistant to high temperatures and chemically inert.

- Thermal Stability: The protection tube should have excellent thermal stability to withstand the high temperatures encountered in various applications without significant deformation or degradation.

- Mechanical strength: The protection tube needs to have sufficient mechanical strength to resist the mechanical stresses that may occur in the application environment, such as pressure or vibration.

- Chemical resistance: The protective tube should be able to resist chemical attack or corrosion by the process medium or atmosphere. This ensures the longevity and reliability of the thermocouple sensor.

- Thermal Conductivity: The thermal conductivity of the protection tube material affects the response time of the thermocouple. Lower thermal conductivity materials can provide better insulation and reduce heat loss, while higher thermal conductivity materials can promote faster response times.

Trusted by Industry Leaders

FAQ

What Are The Applications Of Boron Nitride Ceramic Parts?

What Are The Advantages Of Using Boron Nitride Ceramic Parts?

What Considerations Should Be Made When Selecting Boron Nitride Ceramic Parts?

What Manufacturing Processes Are Used To Produce Boron Nitride Ceramic Parts?

4.8 / 5

This HBN thermocouple tube is a lifesaver! It has protected our sensors from extreme temperatures and corrosive environments, ensuring accurate readings and extending their lifespan.

4.7 / 5

Amazing product! The HBN thermocouple tube's thermal stability and mechanical strength are top-notch. It withstands the harsh conditions of my lab like a champ.

4.9 / 5

I'm thoroughly impressed with the chemical resistance of this HBN thermocouple tube. It has held up remarkably against the corrosive chemicals in our lab, ensuring reliable temperature readings.

4.6 / 5

The thermal conductivity of this HBN tube is exceptional. It provides accurate temperature measurements with minimal heat loss, making it ideal for our high-precision experiments.

4.8 / 5

This HBN thermocouple tube is a game-changer! It has significantly improved the accuracy and response time of our temperature measurements, leading to better process control.

4.7 / 5

The quality of this HBN thermocouple tube is impeccable. It's well-made and durable, providing consistent and reliable temperature readings even in demanding applications.

4.9 / 5

The HBN thermocouple protection tube is a fantastic addition to our lab. Its ability to withstand extreme temperatures and corrosive environments has greatly enhanced the accuracy and reliability of our measurements.

4.6 / 5

I'm highly satisfied with this HBN thermocouple tube. It's a durable and dependable tool that has significantly improved the safety and efficiency of our temperature monitoring system.

4.8 / 5

The HBN thermocouple tube is a true lifesaver. It has protected our sensors from harsh conditions, ensuring continuous and accurate temperature measurements. Highly recommended!

4.7 / 5

This HBN thermocouple tube is a great investment. Its exceptional thermal stability and chemical resistance make it ideal for our high-temperature applications. Highly satisfied!

4.9 / 5

The HBN thermocouple protection tube has exceeded my expectations. It provides accurate and reliable temperature measurements even in the most challenging environments. A must-have for any laboratory!

4.6 / 5

This HBN thermocouple tube is a game-changer. It has significantly improved the accuracy and reliability of our temperature readings, making it an essential tool for our research.

4.8 / 5

I'm thoroughly impressed with the quality and performance of this HBN thermocouple tube. It has become an indispensable tool in our laboratory, providing precise and reliable temperature measurements.

4.7 / 5

The HBN thermocouple protection tube is a valuable addition to our lab equipment. Its durability and resistance to extreme temperatures make it a reliable choice for our demanding applications.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Hexagonal Boron Nitride HBN Ceramic Ring

Boron nitride ceramic (BN) rings are commonly used in high temperature applications such as furnace fixtures, heat exchangers and semiconductor processing.

Advanced Engineering Fine Ceramics Boron Nitride (BN) Ceramic Parts

Boron nitride ((BN) is a compound with high melting point, high hardness, high thermal conductivity and high electrical resistivity. Its crystal structure is similar to graphene and harder than diamond.

Hexagonal Boron Nitride HBN Spacer Cam Profile and Various Spacer Types

Hexagonal boron nitride (HBN) gaskets are made from hot-pressed boron nitride blanks. Mechanical properties similar to graphite, but with excellent electrical resistance.

Boron Nitride (BN) Crucible for Phosphorous Powder Sintered

Phosphorus powder sintered boron nitride (BN) crucible has a smooth surface, dense, pollution-free and long service life.

Custom PTFE Teflon Parts Manufacturer for Centrifuge Tubes

PTFE centrifugal tubes are highly valued for their exceptional chemical resistance, thermal stability, and non-stick properties, making them indispensable in various high-demand sectors. These tubes are particularly useful in environments where exposure to corrosive substances, high temperatures, or stringent cleanliness requirements are prevalent.

Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

Due to the characteristics of boron nitride itself, the dielectric constant and dielectric loss are very small, so it is an ideal electrical insulating material.

High Temperature Alumina (Al2O3) Furnace Tube for Engineering Advanced Fine Ceramics

High temperature alumina furnace tube combines the advantages of high hardness of alumina, good chemical inertness and steel, and has excellent wear resistance, thermal shock resistance and mechanical shock resistance.

Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

Reduce forming pressure & shorten sintering time with Vacuum Tube Hot Press Furnace for high-density, fine-grain materials. Ideal for refractory metals.

Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

Discover the versatility of Laboratory Rotary Furnace: Ideal for calcination, drying, sintering, and high-temperature reactions. Adjustable rotating and tilting functions for optimal heating. Suitable for vacuum and controlled atmosphere environments. Learn more now!

Related Articles

CVD furnace for the growth of carbon nanotubes

Chemical vapor deposition (CVD) furnace technology is a widely used method for growing carbon nanotubes.

Vacuum Induction Furnace Fault Inspection: Essential Procedures and Solutions

Discover the essential procedures for inspecting and troubleshooting common faults in vacuum induction furnace. Learn how to troubleshoot electrical failures, conduct post-operation inspections, maintain records, and monitor the furnace's operation. Take corrective actions to ensure the furnace's optimal performance. Find expert solutions for temperature abnormalities, vacuum level deviations, and furnace chamber inspections.

Hexagonal Boron Nitride: Enhancing Performance in Composite Ceramic Materials

Explores the role of h-BN in various composite ceramics, highlighting its properties and applications.

Choosing the Right Thermocouple for Heat Treatment Processes

A guide to selecting the appropriate thermocouple for heat treatment processes based on standards and application requirements.

The Geometry of Heat: Why Your Furnace Tube Material Dictates Your Science

The material of your furnace tube isn't just a detail; it's a boundary condition for your physics. Discover how to balance Quartz, Alumina, and Alloys.

The Role and Types of Crucibles in Scientific Experiments

Explores the significance and various types of crucibles in scientific experiments, focusing on their materials and applications.

Selecting Heating Elements for Vacuum Furnaces

Guide on choosing heating elements and insulation screens for efficient vacuum furnace operation.

Entropy and the Alumina Tube: The Art of Precision Maintenance

Discover the disciplined approach to cleaning alumina furnace tubes. Learn how to prevent thermal shock, remove residue with acid, and extend equipment life.

The Crucible's Choice: Why Your Furnace Tube Material Defines Experimental Success

Selecting a furnace tube is a critical trade-off between thermal resilience, chemical purity, and operational integrity. Make the right choice.

Comprehensive Overview of Zirconia Ceramic Materials

A detailed exploration of zirconia ceramics, including properties, history, preparation, molding, sintering, and applications.

PTFE gasket: an all-around solution for flange sealing

Polytetrafluoroethylene (PTFE) gaskets have become an ideal choice in the field of flange sealing due to their unique chemical stability and high temperature resistance.

The Ceramic Paradox: Why the Best Way to Clean an Alumina Tube is Not to Clean It

Deep cleaning is often a symptom of process failure. Discover the engineering protocols to maintain alumina tubes, prevent thermal shock, and ensure longevity.