Thin Film Deposition Parts

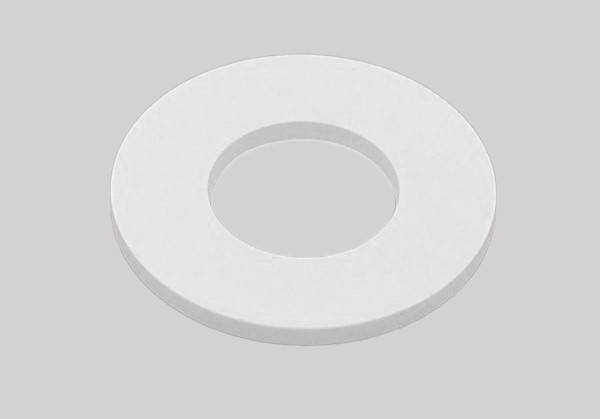

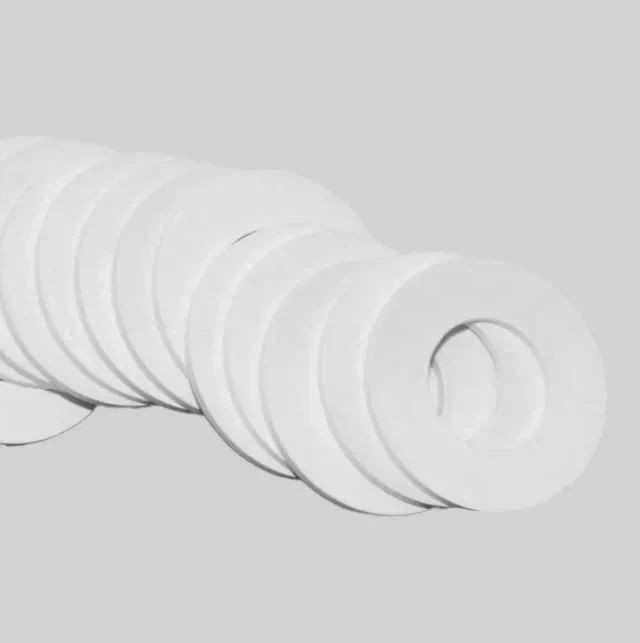

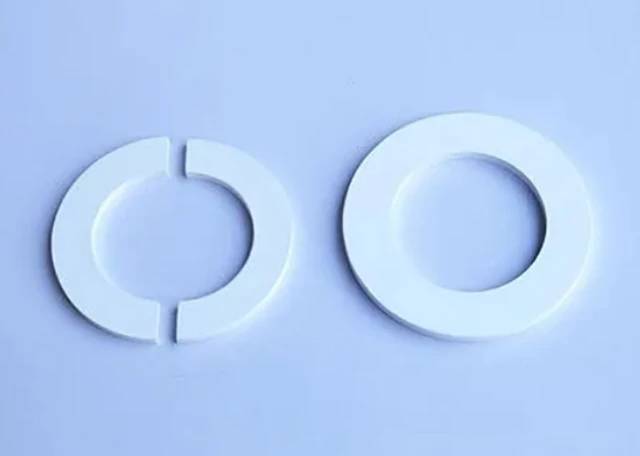

Hexagonal Boron Nitride HBN Spacer Cam Profile and Various Spacer Types

Item Number : KE-D3

Price varies based on specs and customizations

- Material

- Boron nitride

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Application

Hexagonal boron nitride (HBN) gaskets are made of boron nitride (BN), a compound with equal numbers of boron and nitrogen atoms. The hexagonal form (HBN), which corresponds to graphite, is the softest and most stable form of the BN polymorph and is therefore used as a lubricant and cosmetic additive. The diamond-like cubic (CBN) variety is very hard, second only to diamond. The rare wurtzite boron nitride (WBN) metamorphism is similar to siderite and may even be harder than cubic boron nitride.

- Insulator for high temperature furnace

- Feedthroughs for high voltage equipment

- Spacers for glass melting

- Boron Nitride Parts for Ion Implantation Equipment

- Rare earth metal smelting crucible

- Color picture tube heat conduction, heat-resistant support plate

- crystal production nozzle

- electrical insulation parts

Detail & Parts

The products we display are available in different sizes and custom sizes are available upon request.

Advantages

- Low wettability to molten metal

- Relatively high thermal conductivity and low thermal expansion

- High thermal shock resistance

- Extremely high operating temperature with proper inert gas protection (>3000C documented).

- Good thermal performance, high temperature resistance, good thermal stability

- Good electrical insulation, breakdown resistance, low high-frequency dielectric loss

- Good machinability, machining accuracy can reach 0.01mm

- Good chemical stability, no reaction with metal melt and acid contact

- Transmission of infrared rays, transmission of microwaves, absorption of neutrons

- non-toxic

Trusted by Industry Leaders

4.8 / 5

The HBN spacers from KINTEK SOLUTION arrived promptly and were exactly as described. They're perfect for my high-temperature furnace insulation needs.

4.9 / 5

KINTEK SOLUTION's HBN spacers are an excellent value for money. They're durable and have held up well in my vacuum system.

4.7 / 5

I'm very impressed with the quality of KINTEK SOLUTION's HBN spacers. They're well-made and have met all my expectations.

4.8 / 5

I've been using KINTEK SOLUTION's HBN spacers for years and they've never let me down. They're durable and reliable.

5.0 / 5

KINTEK SOLUTION's HBN spacers are technologically advanced and have helped me improve the performance of my high-voltage equipment.

4.9 / 5

I highly recommend KINTEK SOLUTION's HBN spacers for anyone looking for high-quality, durable, and technologically advanced insulation solutions.

4.8 / 5

KINTEK SOLUTION's HBN spacers are a great choice for sintering and melting alloys, ceramics, rare earth, and other materials.

4.7 / 5

I'm satisfied with KINTEK SOLUTION's HBN spacers. They've improved the heat conduction and heat-resistant support plate of my color picture tube.

4.9 / 5

KINTEK SOLUTION's HBN spacers have excellent machinability and machining accuracy, reaching up to 0.01mm.

5.0 / 5

I'm amazed by the good chemical stability of KINTEK SOLUTION's HBN spacers. They don't react with metal melt and acid contact.

4.8 / 5

KINTEK SOLUTION's HBN spacers have good transmission of infrared rays, microwaves, and absorption of neutrons.

4.9 / 5

The non-toxic nature of KINTEK SOLUTION's HBN spacers makes them a safe choice for various applications.

4.7 / 5

I'm impressed with the fast delivery of KINTEK SOLUTION's HBN spacers. They arrived within a week of placing my order.

4.8 / 5

KINTEK SOLUTION's HBN spacers are worth every penny. They're durable and have lasted me for years.

4.9 / 5

I highly recommend KINTEK SOLUTION's HBN spacers to anyone looking for high-quality insulation solutions.

5.0 / 5

KINTEK SOLUTION's HBN spacers are a game-changer for my high-temperature applications. They've improved the performance and efficiency of my equipment.

4.8 / 5

I'm impressed with the low wettability to molten metal of KINTEK SOLUTION's HBN spacers. They've greatly reduced the contamination of my molten metal.

4.7 / 5

KINTEK SOLUTION's HBN spacers have relatively high thermal conductivity and low thermal expansion, making them ideal for my high-temperature applications.

4.9 / 5

I'm very satisfied with the high thermal shock resistance of KINTEK SOLUTION's HBN spacers. They've withstood extreme temperature changes without cracking or breaking.

5.0 / 5

I highly recommend KINTEK SOLUTION's HBN spacers for anyone looking for durable, reliable, and high-performance insulation solutions.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Hexagonal Boron Nitride HBN Ceramic Ring

Boron nitride ceramic (BN) rings are commonly used in high temperature applications such as furnace fixtures, heat exchangers and semiconductor processing.

Hexagonal Boron Nitride HBN Thermocouple Protection Tube

Hexagonal boron nitride ceramics is an emerging industrial material. Because of its similar structure to graphite and many similarities in performance, it is also called "white graphite".

Custom Boron Nitride (BN) Ceramic Parts

Boron nitride (BN) ceramics can have different shapes, so they can be manufactured to generate high temperature, high pressure, insulation and heat dissipation to avoid neutron radiation.

Boron Nitride (BN) Ceramic Rod for High Temperature Applications

Boron nitride (BN) rod is the strongest boron nitride crystal form like graphite, which has excellent electrical insulation, chemical stability and dielectric properties.

Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

High-purity and smooth conductive boron nitride crucible for electron beam evaporation coating, with high temperature and thermal cycling performance.

Advanced Engineering Fine Ceramics Boron Nitride (BN) Ceramic Parts

Boron nitride ((BN) is a compound with high melting point, high hardness, high thermal conductivity and high electrical resistivity. Its crystal structure is similar to graphene and harder than diamond.

Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

Due to the characteristics of boron nitride itself, the dielectric constant and dielectric loss are very small, so it is an ideal electrical insulating material.