Thin Film Deposition Parts

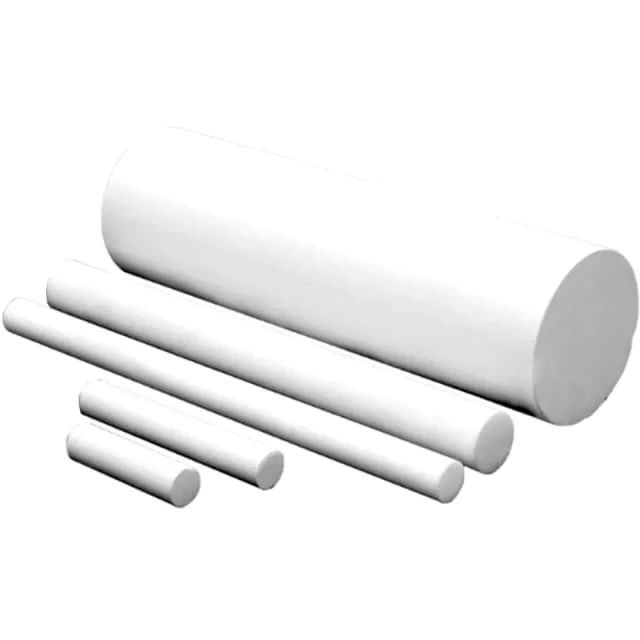

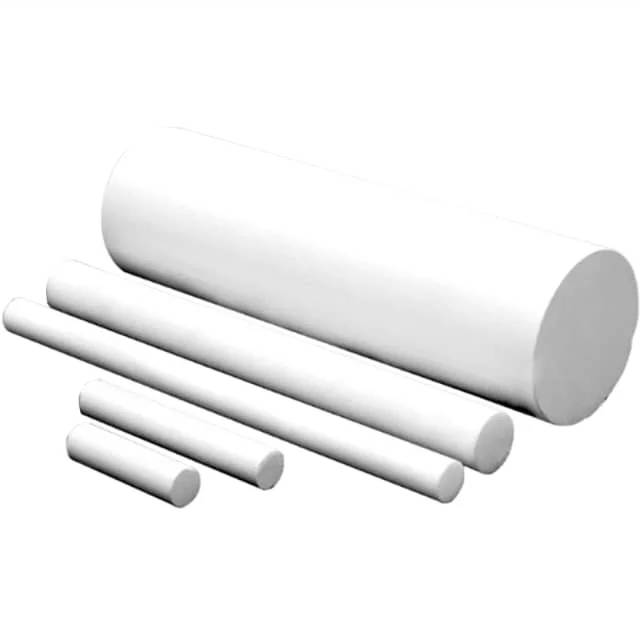

Boron Nitride (BN) Ceramic Rod for High Temperature Applications

Item Number : KM-D4

Price varies based on specs and customizations

- Material

- Boron nitride

- Specification

- Ф10-100mm*100-300mm

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Application

Hexagonal boron nitride is a multifunctional ceramic material composed of equal amounts of boron and nitrogen atoms, which is heat and chemical resistant. It is the strongest boron nitride crystal type along with graphite. Boron nitrogen ceramic rods have the advantages of good chemical properties, good thermal conductivity, low thermal expansion, and microwave transparency. Boron nitride rods can also be machined quickly. Also, glass, salt, and other liquid metals are non-wetting. This ensures that all compounds will not get wet and are more resistant to chemical attack.

- Evaporation boat

- Non-ferrous metal metallurgy nozzle

- Electrical Insulators in Vacuum Systems

- Insulator for high temperature furnace

- Gasket for glass melting

Detail & Parts

Technical specifications

| diameter and length | 10-100mm*100-300mm |

The products we display are available in different sizes and custom sizes are available upon request.

Advantages

- Easy to process

- Low wettability to molten metal

- Low dielectric constant

- High dielectric strength

- High thermal conductivity and low thermal expansion

- High thermal shock resistance

- Extremely high operating temperature (>3000°C) with inert gas protection

Trusted by Industry Leaders

FAQ

What Are The Applications Of Boron Nitride Ceramic Parts?

What Are The Advantages Of Using Boron Nitride Ceramic Parts?

What Considerations Should Be Made When Selecting Boron Nitride Ceramic Parts?

What Manufacturing Processes Are Used To Produce Boron Nitride Ceramic Parts?

4.8 / 5

The BN Ceramic Rod I bought from KINTEK SOLUTION arrived promptly and in perfect condition. I can't wait to try it!

4.7 / 5

I'm incredibly impressed with the quality of the BN Ceramic Rod. It's exactly what I needed for my research project.

4.9 / 5

The durability of this BN Ceramic Rod is outstanding. It's been through multiple experiments and still performs like new.

4.6 / 5

I highly recommend the BN Ceramic Rod from KINTEK SOLUTION. It's an excellent choice for high-temperature applications.

5.0 / 5

This BN Ceramic Rod is top-notch. Its technological advancement is impressive, making it a must-have for any laboratory.

4.8 / 5

The BN Ceramic Rod from KINTEK SOLUTION is a game-changer. Its unique properties make it perfect for my research.

4.7 / 5

I'm thoroughly satisfied with the value for money I got with the BN Ceramic Rod. It exceeds my expectations in terms of performance and durability.

4.9 / 5

The fast delivery of the BN Ceramic Rod was a pleasant surprise. Kudos to KINTEK SOLUTION for their exceptional service.

4.6 / 5

The BN Ceramic Rod is an excellent investment for any laboratory. Its versatility and reliability make it a must-have.

5.0 / 5

I'm blown away by the quality and performance of the BN Ceramic Rod. It's a testament to KINTEK SOLUTION's commitment to excellence.

4.8 / 5

The BN Ceramic Rod has proven to be an invaluable asset in my laboratory. Its durability and resistance to high temperatures are remarkable.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

5L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

KinTek KCBH 5L Heating Chilling Circulator - Ideal for labs and industrial conditions with multi-functional design and reliable performance.

20L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

Maximize lab productivity with KinTek KCBH 20L Heating Chilling Circulator. Its all-in-one design offers reliable heating, chilling, and circulating functions for industrial and lab use.

Double-Layer Water Bath Electrolytic Electrochemical Cell

Discover the temperature-controllable electrolytic cell with a double-layer water bath, corrosion resistance, and customization options. Complete specifications included.

Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

Evaporation boat sources are used in thermal evaporation systems and are suitable for depositing various metals, alloys and materials. Evaporation boat sources are available in different thicknesses of tungsten, tantalum and molybdenum to ensure compatibility with a variety of power sources. As a container, it is used for vacuum evaporation of materials. They can be used for thin film deposition of various materials, or designed to be compatible with techniques such as electron beam fabrication.

Aluminized Ceramic Evaporation Boat for Thin Film Deposition

Vessel for depositing thin films; has an aluminum-coated ceramic body for improved thermal efficiency and chemical resistance. making it suitable for various applications.

Optical Window Glass Substrate Wafer CaF2 Substrate Window Lens

A CaF2 window is an optical window made of crystalline calcium fluoride. These windows are versatile, environmentally stable and resistant to laser damage, and they exhibit a high, stable transmission from 200 nm to about 7 μm.

Related Articles

CVD furnace for the growth of carbon nanotubes

Chemical vapor deposition (CVD) furnace technology is a widely used method for growing carbon nanotubes.

Hexagonal Boron Nitride: Enhancing Performance in Composite Ceramic Materials

Explores the role of h-BN in various composite ceramics, highlighting its properties and applications.

Dos and don'ts during the installation of molybdenum disilicide (MoSi2) heating element

Precautions when installing MoSi2 heating elements

Comparison of Pyrolytic Graphite and Pyrolytic Boron Nitride Crucibles

A detailed comparison of pyrolytic graphite and pyrolytic boron nitride crucibles, focusing on their preparation processes, characteristics, and applications.

Guidelines for the Use of Boron Nitride Crucibles

Instructions on the proper use, precautions, and compatibility of boron nitride crucibles.

Introduction to Various Ceramic Crucibles

An overview of different types of ceramic crucibles, their properties, and applications.

Common Problems and Considerations in Graphite Rods for Vacuum Sintering Furnaces

Discusses the selection, performance, installation, and maintenance of graphite rods in vacuum sintering furnaces.

Graphite Boats in PECVD for Cell Coating

Exploring the use of graphite boats in PECVD for efficient cell coating.

Structure and Properties of High-Temperature Engineering Ceramics

Explore the applications, structural features, and performance advantages of high-temperature engineering ceramics across various industries.