Thin Film Deposition Parts

Aluminized Ceramic Evaporation Boat for Thin Film Deposition

Item Number : KME-DL

Price varies based on specs and customizations

- Material

- Ceramics

- Capacity

- 1ml / 3ml / 5ml

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Application

The inside of the evaporation boat is coated with a layer of aluminum or other metals with excellent heat resistance and chemical resistance to enhance its thermal performance and promote efficient evaporation. Aluminized coatings on ceramic boats serve a variety of purposes. First, it acts as a reflective surface, improving thermal efficiency by reflecting heat back to the material being evaporated. This helps to optimize the deposition process and reduce energy consumption. Ceramic evaporation boats have special electrical and thermal properties, and are ideal materials for vacuum aluminum plating that meet stringent requirements.

- Conductive ceramic material.

- Cathode coating materials for aluminum electrolytic cells.

- PTC heating ceramic material and flexible PTC material.

- In short, containers for various thin film deposition processes, especially vacuum evaporation systems. Commonly used in semiconductor manufacturing, optics, electronics, surface coating and other industries.

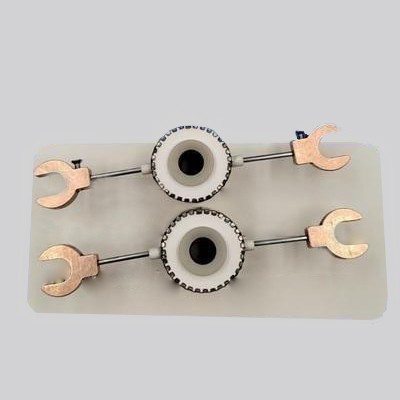

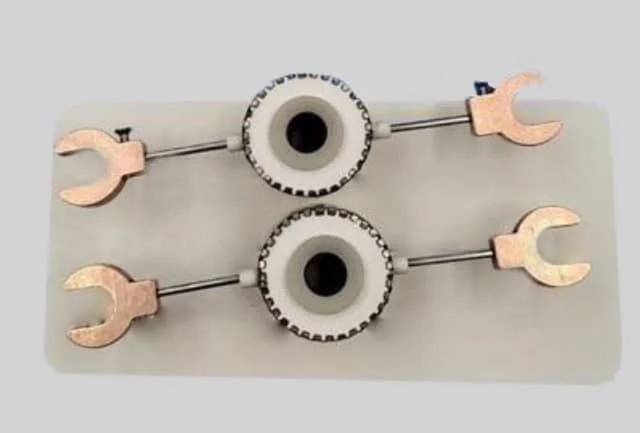

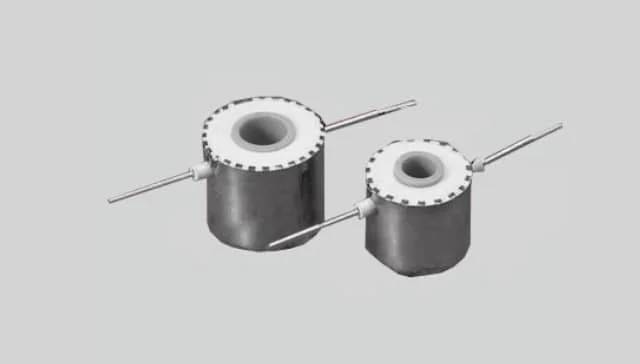

Detail & Parts

The crucibles we show are available in different sizes and custom sizes are available on request.

Advantage

- Good chemical stability

- Excellent thermal shock resistance and bending resistance

- Molten aluminum spreads easily and evenly.

- Uniform evaporation, fast heating speed, high evaporation efficiency

- Good resistance to corrosion from molten aluminum or any other molten metal prolongs the life of the boat.

Trusted by Industry Leaders

FAQ

Characteristics Of Aluminized Ceramic Evaporation Boats.

4.8 / 5

I was impressed with the fast delivery of my order. The evaporation boats arrived in perfect condition and were exactly as described.

4.7 / 5

The aluminized ceramic evaporation boats are a great value for the money. They are well-made and have held up well under heavy use.

4.9 / 5

The quality of the evaporation boats is top-notch. They are made from high-quality materials and are very durable.

4.6 / 5

I have been using these evaporation boats for several months now and they have shown no signs of wear or tear. They are a great investment.

4.8 / 5

The technological advancements in these evaporation boats are impressive. They are very efficient and have helped me to improve the quality of my work.

4.7 / 5

I am very satisfied with these evaporation boats. They are a great addition to my lab and have helped me to streamline my work.

4.9 / 5

These evaporation boats are a game-changer. They have made my work so much easier and more efficient.

4.6 / 5

I would highly recommend these evaporation boats to anyone who is looking for a high-quality and durable product.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

Evaporation boat sources are used in thermal evaporation systems and are suitable for depositing various metals, alloys and materials. Evaporation boat sources are available in different thicknesses of tungsten, tantalum and molybdenum to ensure compatibility with a variety of power sources. As a container, it is used for vacuum evaporation of materials. They can be used for thin film deposition of various materials, or designed to be compatible with techniques such as electron beam fabrication.

1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

KT-TF12 split tube furnace: high-purity insulation, embedded heating wire coils, and max. 1200C. Widely used for new materials and chemical vapour deposition.

Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

Learn about Cylindrical Resonator MPCVD Machine, the microwave plasma chemical vapor deposition method used for growing diamond gemstones and films in the jewelry and semi-conductor industries. Discover its cost-effective advantages over traditional HPHT methods.

Related Articles

A Comparative Study of Evaporation and Sputtering Techniques in Thin Film Deposition

The two most common techniques used for thin film deposition are evaporation and sputtering.

A Comprehensive Guide to Vacuum Coating: Enhancing Performance and Aesthetics

Discover the world of vacuum coating, a process that creates protective and aesthetic layers on metal and plastic surfaces. Explore its types, uses, and benefits, including enhanced performance, extended lifespan, and improved aesthetics.

Understanding Evaporation Boats in Vacuum Coating

An in-depth look at evaporation boats, their materials, arrangement, temperature control, and corrosion issues in vacuum coating processes.

Graphite Boats in PECVD for Cell Coating

Exploring the use of graphite boats in PECVD for efficient cell coating.

Types of Evaporation Sources for Evaporative Coating

Explore different evaporation sources used in thin film deposition, including filaments, crucibles, and evaporation boats.

Rotary Evaporator and Its Application in Traditional Chinese Medicine Refinement

Explores the use of rotary evaporators in the concentration and refinement of traditional Chinese medicine extracts, detailing equipment selection, operation principles, and safety considerations.