Materials for Evaporation Boats

Carbon-Graphite Materials

Carbon-graphite materials are renowned for their exceptional high-temperature resistance, excellent electrical conductivity, low thermal expansion, and superior thermal shock resistance. These properties make them ideal for applications where durability and performance under extreme conditions are paramount. However, their porous nature presents a significant challenge, as it can lead to structural weaknesses and increased susceptibility to breakage during the coating process.

Despite these drawbacks, the chemical inertness of mechanical carbon-graphite grades renders them impervious to most acids, alkalis, solvents, and other corrosive compounds. This characteristic ensures that components made from this material are well-suited for use in environments where corrosion is a major concern, such as in food processing, chemical and fuel handling, and industrial processes involving pumps, vanes, valves, and other critical equipment.

Carbon-graphite materials also excel in applications requiring high thermal conductivity. For instance, graphite furnace is capable of dissipating heat generated by friction at seal faces, effectively diffusing it away from the source. In scenarios where extremely high thermal conductivity is essential, opting for graphitized or metal-impregnated grades can further enhance performance.

Graphite, in particular, is frequently utilized in high-temperature applications due to its ability to maintain thermal stability and dimensional integrity even at temperatures exceeding 5000°F. Its versatility extends to recreational products like kite frames, tent poles, kayak riggers, and fishing rods, where its excellent corrosion resistance and thermal shock resistance make it the material of choice for items exposed to harsh environmental conditions.

Boron Nitride Ceramic Materials

Boron Nitride (BN) materials are renowned for their exceptional properties, making them highly suitable for a variety of demanding applications in high-temperature and high-vacuum environments. These materials offer unparalleled thermal stability, maintaining their structural integrity even under extreme temperatures. Their chemical stability ensures resistance to corrosive agents, making them ideal for use in environments where other materials would degrade rapidly.

One of the standout features of BN is its electrical insulation capability, which is crucial in applications such as electric insulators in vacuum systems and feedthroughs for high-voltage equipment. Additionally, BN exhibits high thermal conductivity, facilitating efficient heat distribution and management in high-temperature processes. This property is further enhanced when BN is combined with materials like TiB2, creating composites that offer superior thermal conductivity and electrical resistivity.

BN ceramics, particularly Hexagonal Boron Nitride (H-BN), are also known for their ease of processing. Unlike other high-temperature materials that may be brittle and difficult to shape, BN ceramics can be easily machined into various forms, such as crucibles for crystal growth and break rings for horizontal casting machines. This versatility, combined with their self-lubricating properties, makes BN ceramics an excellent choice for applications requiring both mechanical durability and lubricity in high-vacuum conditions.

In summary, BN materials are not only thermally and chemically stable but also possess excellent electrical insulation and thermal conductivity properties. Their ease of processing and self-lubricating capabilities further enhance their utility in a wide array of industries, making them a cornerstone material in high-temperature and high-vacuum applications.

Evaporation Boat Arrangement

Straight Line Arrangement

Straight line arrangement of evaporation boats can significantly impact the efficiency and stability of the vacuum coating process. One of the primary issues with this arrangement is the potential for poor electric contact and heat conduction between the boats. This can lead to uneven heating, where some parts of the evaporation boat may become hotter than others, causing localized evaporation rates that deviate from the desired uniformity.

Moreover, the straight line configuration can exacerbate thermal gradients, leading to thermal stress within the evaporation boats. This stress can cause mechanical deformation or even fracture, especially in materials that are prone to thermal shock, such as carbon-graphite. The result is a higher likelihood of process interruptions and a reduced lifespan for the evaporation boats.

| Issue | Impact on Evaporation Process |

|---|---|

| Poor Electric Contact | Uneven heating and localized evaporation rates |

| Poor Heat Conduction | Increased thermal gradients and thermal stress |

| Mechanical Deformation | Higher risk of process interruptions and boat failure |

To mitigate these issues, alternative arrangements, such as the staggered configuration, are often preferred. Staggered arrangements ensure better mutual support of vapor clouds, leading to more uniform coating even at high-speed operations. This approach not only improves the overall quality of the coating but also enhances the reliability and longevity of the evaporation boats.

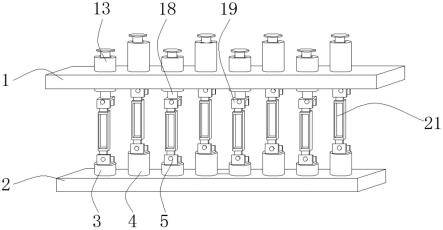

Staggered Arrangement

Staggered arrangement in evaporation boat setups is a strategic method designed to optimize the distribution and interaction of vapor clouds. This configuration ensures that the vapor clouds generated from each boat can mutually support and enhance each other, leading to a highly uniform coating even when the coating process is conducted at high speeds.

By positioning the evaporation boats in a staggered pattern, the system can mitigate the risks associated with straight line arrangements, such as poor electric contact and heat conduction issues. The staggered arrangement facilitates better heat distribution and more effective vapor cloud interaction, which are crucial for maintaining the stability and efficiency of the evaporation process.

Moreover, this arrangement helps in achieving a more consistent and uniform coating thickness across the entire substrate. The mutual support of vapor clouds ensures that no part of the substrate is left under-coated or over-coated, thereby enhancing the overall quality and reliability of the coating process. This method is particularly advantageous in high-speed coating applications where maintaining uniformity is challenging but essential for the final product's integrity.

Temperature Control

Purpose of Temperature Control

Temperature control in vacuum coating processes serves multiple critical functions. Primarily, it ensures that the aluminum layer thickness meets precise specifications, which is crucial for achieving the desired optical and physical properties of the coated material. By maintaining a consistent temperature, the process can produce a uniform aluminum film, which is essential for the even distribution of the coating across the substrate.

Moreover, effective temperature management significantly extends the life of the evaporation boat. High temperatures can cause rapid degradation of the boat's material, leading to frequent replacements and increased operational costs. By optimizing temperature control, the evaporation boat can operate more efficiently and sustainably, reducing the frequency of maintenance and downtime.

Surface cleaning and graphite brushing are integral to this process. Regular cleaning removes contaminants that could affect the uniformity of the aluminum film, while graphite brushing helps in maintaining the boat's surface integrity, preventing cracks and ensuring smooth operation. These practices are not just maintenance tasks but are fundamental to the overall efficiency and reliability of the vacuum coating process.

In summary, temperature control is not merely a technical requirement but a strategic imperative that impacts the quality of the final product, the longevity of the equipment, and the overall operational efficiency of the vacuum coating process.

Evaporation Boat Corrosion and Solutions

Corrosion Process

Corrosion in evaporation boats is a critical issue that significantly impacts the performance and longevity of vacuum coating processes. This phenomenon primarily involves the reaction between liquid aluminum and boron nitride (BN), a common material used in evaporation boats due to its high thermal stability and chemical stability. When liquid aluminum reacts with BN, it forms aluminum nitride (AlN), a compound that is neither conductive nor thermally stable. This reaction not only reduces the thickness of the evaporation boat but also increases its electrical resistance.

As the thickness of the evaporation boat decreases, its ability to conduct heat effectively is compromised, leading to a drop in temperature. This temperature decrease can have several adverse effects on the coating process. Firstly, it may result in uneven film deposition, affecting the uniformity and quality of the final product. Secondly, the increased resistance can cause localized heating, leading to potential structural failures in the boat. Over time, these cumulative effects can lead to the eventual failure of the evaporation boat, necessitating replacement and disrupting the production process.

Understanding the corrosion process is essential for developing effective preventive measures. By monitoring the conditions that promote this reaction and implementing strategies to mitigate them, it is possible to extend the life of evaporation boats and ensure more consistent and reliable vacuum coating outcomes.

Prevention and Solutions

To mitigate corrosion in evaporation boats, several strategic measures can be implemented. Firstly, selecting high-density evaporation boats is crucial. These boats are less porous, reducing the likelihood of corrosive elements penetrating and reacting with the boat material. High-density boats also offer better structural integrity, which is essential for maintaining the boat's performance over time.

Maintaining a stable melt pool area is another critical factor. By ensuring that the melt pool remains consistent in size and temperature, the risk of localized overheating and subsequent corrosion is minimized. This stability can be achieved through precise temperature control and regular monitoring of the melt pool conditions.

Delaying temperature increases is also an effective preventive measure. Rapid temperature changes can exacerbate corrosion by causing thermal stress and weakening the boat material. By gradually increasing the temperature, the evaporation boat can acclimate more smoothly, reducing the chances of thermal shock and corrosion.

| Prevention Strategy | Description |

|---|---|

| High-Density Boats | Less porous, better structural integrity, reduces corrosive penetration |

| Stable Melt Pool Area | Consistent size and temperature, minimizes localized overheating |

| Delayed Temperature Increases | Gradual temperature changes, reduces thermal stress and corrosion risk |

These strategies collectively contribute to extending the lifespan of evaporation boats, ensuring more reliable and consistent vacuum coating processes.

Related Products

- Evaporation Boat for Organic Matter

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

- Ceramic Evaporation Boat Set Alumina Crucible for Laboratory Use

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- Tungsten Evaporation Boat for Thin Film Deposition

Related Articles

- A Comparative Study of Evaporation and Sputtering Techniques in Thin Film Deposition

- What Is Boiling Point Rise In Evaporators?

- How to Choose the Best Rotary Evaporator (Rotavapor) for Your Budget

- The Effect of Powder Moisture Content on Cold Isostatic Pressing

- Mastering the Art of Rotary Evaporation