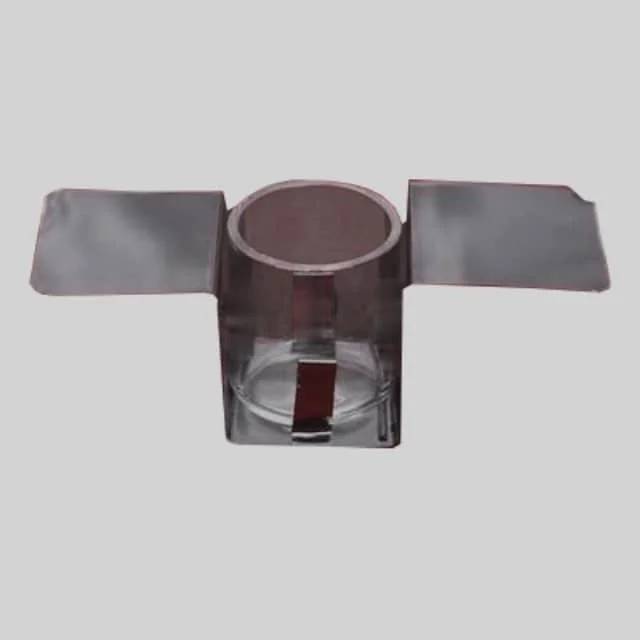

Thin Film Deposition Parts

Evaporation Boat for Organic Matter

Item Number : KME-YJ

Price varies based on specs and customizations

- Material

- Molybdenum / Quartz / Boron Nitride

- Specification

- Ф18*20 / 13*13mm

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Application

Evaporation boats serve as vessels for the analysis of materials and products; designed for combustion of solid materials. Evaporation boats for organics are commonly used in techniques such as physical vapor deposition (PVD), where thin films are deposited onto substrates by condensing evaporated material. They provide a controlled environment for the evaporation of organic materials while preventing contamination of the boat material itself.

In conclusion, organic evaporation boats enable controlled evaporation and material deposition for the production of thin films, coatings, organic electronics, OLEDs and other applications requiring precise evaporation of organic materials.

Detail & Parts

Technical specifications

Size: Ф18*20mm / Ф13*13mm

The crucibles we show are available in different sizes and custom sizes are available on request.

Advantage

- Controlled Evaporation: They allow precise control of evaporation rate, temperature and deposition parameters, ensuring uniform and high quality films or coatings.

- Versatility: They can accommodate a variety of organic materials, making them suitable for a variety of applications in the fields of electronics, optoelectronics, photovoltaics, and coatings.

- High-purity deposition: They are made of high-purity materials, minimizing contamination and enabling the deposition of pure organic materials.

- Efficient heat transfer: Its design and thermal conductivity optimize energy use, increase evaporation rates and increase process efficiency.

- Precise film thickness control: By adjusting parameters such as time, temperature, and deposition rate, the film thickness can be precisely controlled.

- Compatibility with vacuum system: It can withstand vacuum environment to ensure stable evaporation and no pollution.

- Research flexibility: It is widely used in research and development, promotes the exploration and research of different organic compounds, and promotes innovation in various fields.

These advantages make evaporation boats essential for high-quality thin film production, coatings, electronics, and applications requiring controlled evaporation of organic materials.

Precautions

- Use a crucible or sagger to hold the analyte while heating.

- Considering the specific characteristics of equipment and products, gradually adjust the heating temperature.

- Avoid rapid heating or rapid cooling to prevent damage to the evaporation boat. Best practice is to slow down the heating process and ensure the longevity of the boat.

Trusted by Industry Leaders

FAQ

What Are The Advantages Of Using Evaporation Boats?

What Is The Typical Lifespan Of An Evaporation Boat?

Can Evaporation Boats Be Reused?

How Do You Select The Appropriate Evaporation Boat Material?

4.8 / 5

Excellent quality and craftsmanship. The evaporation boat performs consistently and has significantly improved our thin-film deposition process.

4.9 / 5

KINTEK SOLUTION's evaporation boat is a game-changer for our research. It provides precise control over evaporation, leading to consistent and high-quality results.

4.7 / 5

The speed of delivery was impressive. I received the evaporation boat within a few days of placing the order, which allowed us to continue our research without delay.

4.8 / 5

The evaporation boat is a great value for money. Its durability and performance make it a cost-effective choice for our laboratory.

4.9 / 5

The technological advancement of this evaporation boat is remarkable. It has enabled us to achieve higher precision and accuracy in our thin-film deposition experiments.

4.7 / 5

I highly recommend KINTEK SOLUTION's evaporation boat to anyone working with organic materials. Its controlled evaporation and high-purity deposition are invaluable assets.

4.8 / 5

The evaporation boat's precise film thickness control has allowed us to create thin films with exceptional uniformity and reproducibility.

4.9 / 5

The compatibility of this evaporation boat with our vacuum system has made it an integral part of our research setup. It has enhanced the stability and reliability of our experiments.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Evaporation Crucible for Organic Matter

An evaporation crucible for organic matter, referred to as an evaporation crucible, is a container for evaporating organic solvents in a laboratory environment.

Tungsten Evaporation Boat for Thin Film Deposition

Learn about tungsten boats, also known as evaporated or coated tungsten boats. With a high tungsten content of 99.95%, these boats are ideal for high-temperature environments and widely used in various industries. Discover their properties and applications here.

Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

Used for gold plating, silver plating, platinum, palladium, suitable for a small amount of thin film materials. Reduce the waste of film materials and reduce heat dissipation.

Related Articles

Mastering the Art of Rotary Evaporation

Rotary evaporation is a technique used in laboratories to remove solvents from samples through the process of evaporation.

A Comparative Study of Evaporation and Sputtering Techniques in Thin Film Deposition

The two most common techniques used for thin film deposition are evaporation and sputtering.

Boost Your Efficiency Why A Rotary Evaporator Is Better

Rotary evaporation is a technique used to remove solvents from samples, typically with the use of a vacuum. This method is widely used in laboratories due to its efficiency, safety, and cost-effectiveness.

Comparing Chemical Vapor Deposition and Physical Vapor Deposition

Chemical Vapor Deposition (CVD) VS Physical Vapor Deposition (PVD)

What Is Boiling Point Rise In Evaporators?

The evaporators produce concentrated solution having substantially higher boiling point than that of the solvent (of the solution) at the prevailing pressure.

Biomass Pyrolysis An Effective Means of Producing Biofuels

Biomass pyrolysis is a process that involves heating organic matter in the absence of oxygen to break it down into smaller molecules. This technology has gained popularity due to its potential to produce biofuels.

The Importance of Activated Carbon Regeneration in Water Treatment

In water treatment, activated carbon is often used as a means of removing unwanted contaminants, such as chlorine, chloramines, and organic matter, from drinking water and wastewater.

How to Choose the Best Rotary Evaporator (Rotavapor) for Your Budget

A rotary evaporator, also known as a rotavapor, is a laboratory equipment used for distillation, evaporation, and separation of solvents.

Understanding Evaporation Boats in Vacuum Coating

An in-depth look at evaporation boats, their materials, arrangement, temperature control, and corrosion issues in vacuum coating processes.

The Effect of Powder Moisture Content on Cold Isostatic Pressing

Cold Isostatic Pressing (CIP) is a manufacturing process used to create high-density ceramics and metals. This process involves placing the powder into a flexible mold, which is then pressurized with a liquid medium to create a uniform density.

Graphite Boats in PECVD for Cell Coating

Exploring the use of graphite boats in PECVD for efficient cell coating.

Types of Evaporation Sources for Evaporative Coating

Explore different evaporation sources used in thin film deposition, including filaments, crucibles, and evaporation boats.