Introduction

Biomass pyrolysis is a process that involves heating organic matter in the absence of oxygen to break it down into smaller molecules. This technology has gained popularity due to its potential to produce biofuels, which are renewable energy sources that can reduce greenhouse gas emissions. Biomass pyrolysis has several benefits, including the production of biochar, a material that can be used as a soil amendment. However, there are also drawbacks, such as the need for high temperatures and the release of harmful gases. Despite these challenges, biomass pyrolysis has the potential to play a significant role in the production of biofuels and the reduction of greenhouse gas emissions.

Table of Contents

Definition of Biomass Pyrolysis

Biomass pyrolysis is a thermal decomposition process that involves heating organic materials such as wood, agricultural waste, and other biomass, in the absence of oxygen. The process breaks down complex organic compounds into simpler components such as gases, liquids, and solids. This method produces biofuels that can be used for various purposes, including heating, transportation, and electricity generation.

The Pyrolysis Process

The pyrolysis process involves heating the biomass feedstock at high temperatures, typically between 500-600 degrees Celsius, in the absence of oxygen. The biomass is broken down into three main product streams - biochar, pyrolysis gas, and bio-oil.

Biochar

Biochar is a solid product that is produced during the pyrolysis process. It is a form of charcoal that is rich in carbon and is used as a soil amendment to improve soil fertility and reduce carbon emissions.

Pyrolysis Gas and Bio-oil

Pyrolysis gas is a mixture of gases that are produced during the pyrolysis process, including hydrogen, methane, and carbon monoxide. Pyrolysis gas can be used directly for heating and cooking, as well as for electricity generation.

Bio-oil is a liquid product that is also produced during the pyrolysis process. It can be used as a fuel, but its most valuable application is as a feedstock in the chemical industry.

Types of Biomass Pyrolysis

There are three main types of biomass pyrolysis - fast, intermediate, and slow. Fast pyrolysis is the most common method of biomass pyrolysis, which produces a high yield of bio-oil. Intermediate and slow pyrolysis methods produce higher yields of biochar but lower yields of bio-oil.

Advantages and Disadvantages

Biomass pyrolysis has several advantages over traditional fossil fuels. It is a renewable and sustainable source of energy that does not contribute to greenhouse gas emissions. The process also produces valuable byproducts such as biochar, which can be used as a soil amendment to improve soil fertility and reduce carbon emissions.

However, biomass pyrolysis also has some disadvantages. It requires high capital and operating costs, and there are technical challenges in scaling up the process. There is also a potential for emissions of pollutants such as particulate matter and volatile organic compounds. Further research and development are needed to improve process efficiency and product yields.

In conclusion, biomass pyrolysis is a promising method of producing renewable energy and reducing greenhouse gas emissions. The process offers a sustainable and carbon-neutral source of energy and materials.

Benefits of Biomass Pyrolysis

Biomass pyrolysis has gained increasing attention as an effective means of producing biofuels from organic materials such as wood, agricultural waste, and plant matter. This process involves heating the biomass in the absence of oxygen, which causes it to break down into a variety of useful products, including bio-oil, biochar, and syngas. Here are some of the benefits of using biomass pyrolysis as a means of producing biofuels:

1. Sustainable and Environmentally Friendly

Biomass pyrolysis is a more sustainable and environmentally friendly alternative to traditional fossil fuels, as it relies on renewable sources of energy. Using biomass instead of fossil fuels helps to reduce dependence on non-renewable energy sources, which will have an impact on reducing pollution caused by burning fossil fuels.

2. Production of Valuable By-Products

The pyrolysis process can produce valuable by-products such as bio-oil, biochar, and syngas, which can be used as fuel, fertilizer, or in other industrial applications. This makes biomass pyrolysis a versatile option for different regions and industries.

3. Low Emissions

Biomass pyrolysis produces significantly lower emissions compared to traditional fossil fuel combustion. This is because it produces biofuels that are cleaner and less polluting than fossil fuels.

4. Carbon Neutral

Biomass is a renewable resource, and pyrolysis does not release more CO2 than the biomass absorbed during growth, making the process carbon neutral. This means that biomass pyrolysis has a lower carbon footprint compared to other methods of energy production.

5. Flexibility

Biomass pyrolysis can be adapted to work with a variety of feedstocks, making it a versatile option for different regions and industries. It can be used to produce different types of biofuels, including liquid and gaseous fuels, which can be tailored to suit different applications.

6. Waste Reduction

Biomass pyrolysis can help to reduce waste and promote the circular economy, by converting organic waste materials into useful products. This makes the process more sustainable and less wasteful.

Despite the advantages of biomass pyrolysis, there are also some disadvantages to consider. High capital costs, complexity, feedstock variability, energy consumption, product variability, and pollution are some of the challenges that need to be addressed to fully realize the potential benefits of this process. However, with ongoing research and development, biomass pyrolysis has the potential to play a key role in the transition towards a more sustainable and low-carbon future.

Drawbacks of Biomass Pyrolysis

High Production Cost

One of the main drawbacks of biomass pyrolysis is the high cost of production. This includes the cost of feedstock, equipment, and energy required for the process. The process requires high temperatures and long residence time, which results in high energy consumption. The equipment and machinery required for the process are also costly and require significant investment. Additionally, the process produces a mixed product stream that requires further separation and purification before it can be used. This can be a challenging and time-consuming process, adding to the overall cost of the process.

Competition with Food Production

Another major concern associated with biomass pyrolysis is the competition with food production, leading to concerns about food security. The use of biomass for pyrolysis may compete with food production, as land that could be used to grow food crops may instead be used to grow biomass crops for pyrolysis production. This could lead to a reduction in food production and an increase in food prices, ultimately affecting the food security of the population.

Emissions of Air Pollutants

Biomass pyrolysis also has some negative impacts on human health and the environment due to the emissions of air pollutants. The emissions of harmful gases such as carbon monoxide, nitrogen oxides, and particulate matter could have negative impacts on human health and the environment. The use of low-quality feedstocks can further exacerbate these emissions, producing more harmful gases that could be detrimental to human health and the environment.

Water Consumption

The process of biomass pyrolysis requires significant amounts of water, which could pose a challenge if not properly managed. The water used for the process can become contaminated with pollutants, making it difficult to dispose of properly. This can lead to water pollution, which could ultimately affect the environment and human health.

In conclusion, while biomass pyrolysis remains a promising technology in the production of biofuels, it also has some drawbacks that must be considered. High production costs, competition with food production, emissions of air pollutants, and significant water consumption are all factors that must be addressed to make the process more sustainable and cost-effective. However, with further research and development, these drawbacks can be addressed, and biomass pyrolysis can become a more effective means of producing renewable energy.

Three Types of Biomass Pyrolysis

Biomass pyrolysis is an efficient and cost-effective process of producing renewable energy with minimal environmental impact. The process involves heating organic materials such as wood, agricultural waste, and municipal solid waste in the absence of oxygen to produce biofuels. There are three main types of biomass pyrolysis: fast pyrolysis, slow pyrolysis, and torrefaction.

Fast Pyrolysis

Fast pyrolysis is the most common and widely used method of pyrolysis. It involves heating biomass at high temperatures between 400 and 600°C for less than 2 seconds to produce bio-oil, a liquid fuel. The process is rapid and efficient and produces a high yield of bio-oil. Fast pyrolysis is commonly used for the production of biofuels.

Slow Pyrolysis

Slow pyrolysis, on the other hand, involves heating the biomass at lower temperatures between 300 and 500°C for several hours to produce biochar, a solid fuel, and bio-oil. This method is more suitable for the production of biochar for soil amendment. Slow pyrolysis produces a higher yield of biochar and is more suitable for the production of biochar.

Torrefaction

Finally, torrefaction is a mild form of pyrolysis that involves heating the biomass at temperatures between 200-300°C for 30 minutes to 1 hour to produce torrefied biomass, which can be used as a solid fuel. The process is similar to slow pyrolysis, but with shorter residence time and lower temperatures. Torrefaction is used to improve the properties of biomass, making it more suitable for use as a fuel.

In conclusion, the choice of pyrolysis method depends on the type of biomass being used and the desired end product. Fast pyrolysis is more suitable for the production of biofuels, while slow pyrolysis is more suitable for the production of biochar. Torrefaction is useful for improving the properties of biomass for use as fuel. Each method has its own advantages and disadvantages, and the choice of method depends on the specific needs of the user.

Products of Biomass Pyrolysis

Biomass pyrolysis is a promising technology for producing renewable biofuels. This process involves the thermal decomposition of organic materials, such as wood, agricultural waste, and forestry residues, in the absence of oxygen. The process produces a range of valuable products including biochar, bio-oil, and syngas.

Biochar

Biochar is a solid carbon-rich material that has been widely recognized for its potential to improve soil fertility, sequester carbon, and mitigate climate change. It is produced by heating biomass to high temperatures in the absence of oxygen, a process known as pyrolysis. The resulting biochar is a highly porous material that can retain water and nutrients, making it an ideal soil amendment. Biochar has been shown to improve soil structure, increase nutrient retention, and enhance plant growth.

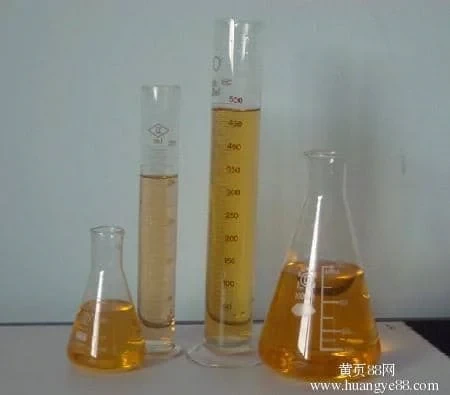

Bio-oil

Bio-oil is a liquid product that can be refined into a range of transportation fuels and chemicals. It is produced through the fast pyrolysis of biomass, which involves heating the biomass to temperatures of around 500-600°C in the absence of oxygen. The resulting liquid is a dark brown, viscous oil that contains a range of chemicals, including alkanes, phenols, ketones, and esters. Bio-oil has the potential to replace fossil fuels in many applications, including transportation, heating, and electricity generation.

Syngas

Syngas is a mixture of carbon monoxide, hydrogen, and other gases that can be used as a fuel for electricity generation or converted into other value-added products. It is produced through the gasification of biomass, which involves heating the biomass to temperatures of around 800-1000°C in the presence of a gasifying agent, such as air or steam. The resulting syngas can be used directly in gas engines or turbines to generate electricity or further processed to produce chemicals or fuels.

In conclusion, biomass pyrolysis is a promising technology for producing renewable biofuels. It utilizes locally available and renewable resources, reduces greenhouse gas emissions, and can contribute to rural development and job creation. The commercial viability of biomass pyrolysis is still dependent on the development of efficient and cost-effective technologies, as well as the establishment of appropriate policy and regulatory frameworks to support the growth of the biofuels industry.

Feedstocks for Biomass Pyrolysis

Biomass pyrolysis is an effective means of producing biofuels from a wide range of feedstocks. The feedstocks used for biomass pyrolysis can include agricultural residues, forestry waste, energy crops, and municipal solid waste.

Agricultural Residues

Agricultural residues refer to the by-products of various agricultural practices, such as straw, husks, cobs, and stalks. These residues are often considered waste materials and are burned or left to decompose in the field. However, they can be used as feedstocks for biomass pyrolysis, providing a valuable source of renewable energy.

Forestry Waste

Forestry waste includes tree branches, bark, and other wood residues generated during the logging and milling of wood products. These residues can be used as feedstocks for biomass pyrolysis, providing a renewable source of energy that is often underutilized.

Energy Crops

Energy crops are crops grown specifically for their energy content, such as switchgrass, willow, and miscanthus. These crops are grown on marginal land that is not suitable for food production and can be harvested and used as feedstocks for biomass pyrolysis.

Municipal Solid Waste

Municipal solid waste includes household and commercial waste, such as food scraps, paper, and plastic. This waste can be sorted and processed to remove non-biodegradable materials and used as feedstocks for biomass pyrolysis, providing a valuable source of renewable energy and reducing the amount of waste sent to landfills.

In conclusion, biomass pyrolysis can utilize a wide range of feedstocks to produce valuable biofuels, such as bio-oil, bio-char, and syngas, which can be used for a variety of applications. The use of these feedstocks can reduce greenhouse gas emissions, reduce dependence on fossil fuels, and promote sustainable agriculture. As research and development in the field of biomass pyrolysis continues, it is likely that this technology will play an increasingly important role in meeting the growing demand for renewable energy.

Conclusion

Biomass pyrolysis is a promising technology for producing biofuels and reducing greenhouse gas emissions. Through this process, biomass is heated in the absence of oxygen, producing bio-oil, biochar, and syngas. These products have a wide range of applications, including heating, electricity generation, and transportation fuel. While there are some drawbacks to biomass pyrolysis, such as the need for large amounts of feedstock and complex processing equipment, the benefits outweigh the drawbacks. The use of biomass pyrolysis can help promote sustainable development and reduce our dependence on fossil fuels.

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

Related Articles

- Exploring the Benefits and Applications of Rotary Furnaces: A Comprehensive Guide

- Rotary Furnaces: A Comprehensive Guide to Advanced Materials Processing

- Optimizing Industrial Processes: Rotary Kiln and Laboratory Furnace Solutions

- Electric Rotary Kiln Pyrolysis Furnace: A Comprehensive Guide to Pyrolysis Technology

- The Advantages and Disadvantages of Different Biomass Feedstocks for Pyrolysis