battery material

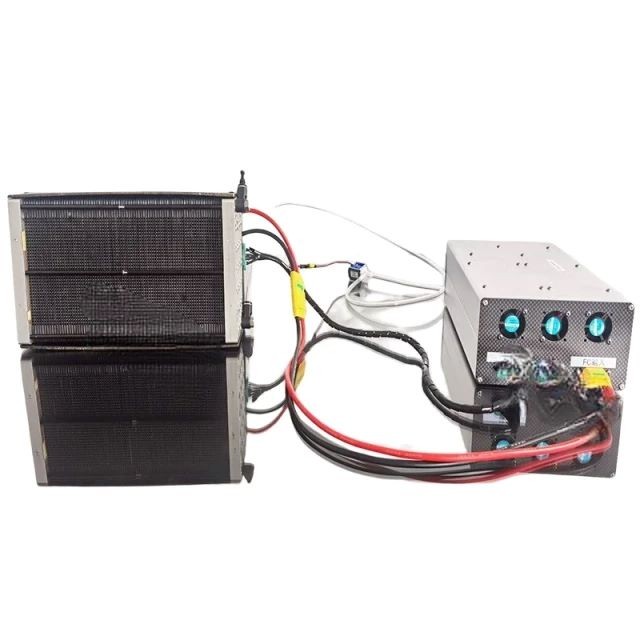

Hydrogen Fuel Cell Stack Battery Lab Equipment

Item Number : BC-05

Price varies based on specs and customizations

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Reliable PartnerEasy ordering process, quality products, and dedicated support for your business success.

Application

The fuel cell stack is the core of the fuel cell system, responsible for directly converting chemical energy into electrical energy. It achieves this by converting fuel, typically hydrogen, and oxygen into electricity and water through special reactions.

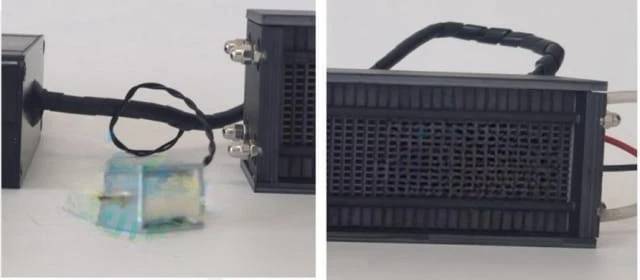

A fuel cell stack is composed of individual fuel cells connected together to generate electricity for various applications. Each fuel cell in the stack consists of two electrodes (cathode and anode) separated by an electrolyte. When hydrogen fuel and an oxidant (usually oxygen from the air) are provided to the fuel cell, a chemical reaction occurs at the electrodes, producing electricity.

The fuel cell stack finds applications in various fields, including fuel cell electric bicycles, communication base stations, unmanned aerial vehicles, portable power supplies, and backup power supplies.

Detail & Parts

Advantages

- Efficient energy conversion: It can convert fuel into electrical energy with an efficiency of over 40%, far superior to traditional methods. This means it uses energy more efficiently and improves overall energy utilization.

- Environmentally friendly: The stack runs on hydrogen or hydrogen-based fuel and produces only water and heat as by-products. It contains no harmful emissions and is green and environmentally friendly.

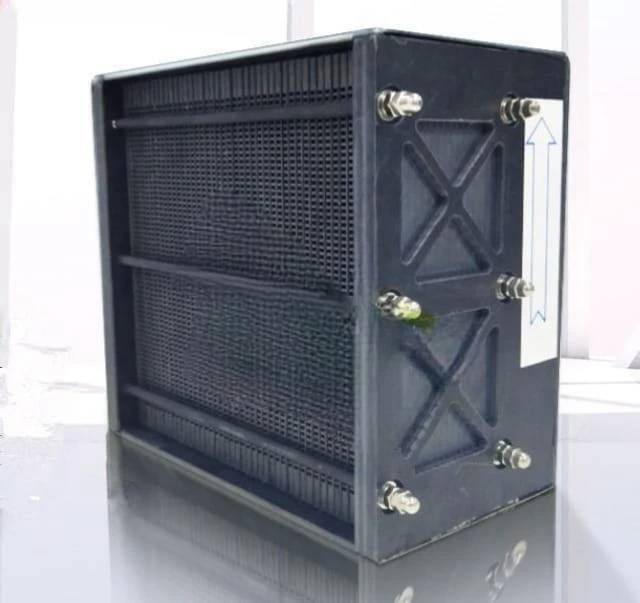

- Stable and reliable: The fuel cell stack is simple in design, has no moving parts, and is very stable and reliable. It runs quietly and lasts longer than traditional energy devices such as internal combustion engines.

- Fast start-up and response: Fuel cell stacks start up quickly and respond to energy demands without waiting for warm-up time, making them ideal for applications such as electric vehicles and drones.

- Complementary with other energy sources: It can be combined with other energy systems to efficiently utilize and store various energy sources. For example, renewable energy sources such as solar and wind power can produce hydrogen for fuel cell stacks, which can then be converted into electricity for different uses.

- In summary, fuel cell stacks are a versatile, clean and reliable technology for generating electricity from hydrogen and oxygen, offering fast response times and being compatible with other energy sources.

Technical specifications

| Model | 10W | 20W | 30W | 50W | 100W | 200W | 300W | 500W |

| Rated output | 10W | 20W | 30W | 50W | 100W | 200W | 300W | 500W |

| Rated voltage (V) | 6.6 | 1.2 | 7.2 | 12 | 12 | 24 | 38 | 24 |

| Rated current (A) | 1.51 | 1.67 | 4.17 | 4.2 | 8.34 | 8.34 | 7.9 | 20.84 |

| Fan voltage (V) | 4-12V | |||||||

| Stack temperature | <53℃ | <56℃ | ||||||

| Stack efficiency | 50% | |||||||

| Slices | 11 pieces | 20 pieces | 12 pieces | 20 pieces | 20 pieces | 40 pieces | 64 pieces | 60 pieces |

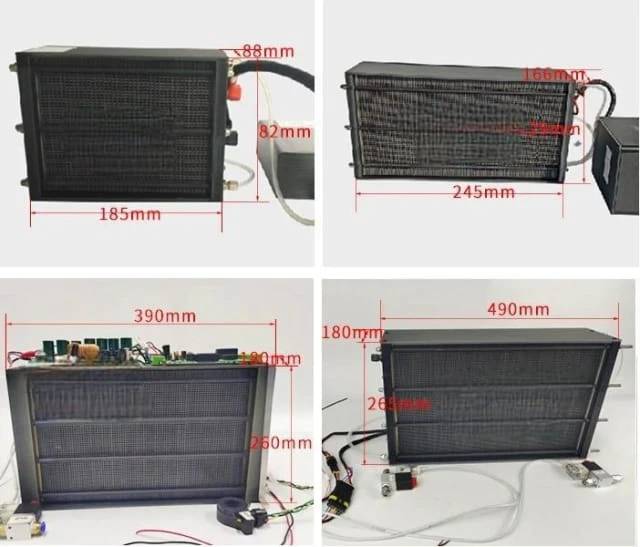

| Volume (mm) | 57*42*52 | 110*46*48 | 84*64*76 | 92*83*56 | 160*143*75 | 104*170*70 | 245*100*100 | 140*180*167 |

| Weight (kg) | 0.155 | 0.29 | 0.2 | 0.3 | 0.8 | 1.01 | 1.5 | 1.95 |

FAQ

What Is A Fuel Cell Stack?

How Does It Work?

The Composition Of The Fuel Cell Stack:

How Much Power Is Generated?

4.8

out of

5

The fuel cell stack's efficiency in energy conversion is remarkable, leading to improved energy utilization.

4.9

out of

5

I appreciate the environmentally friendly nature of the fuel cell stack, emitting only water and heat as by-products.

4.7

out of

5

The stack's stable and reliable operation, with no moving parts, ensures longevity and consistent performance.

4.8

out of

5

The fast start-up and response of the fuel cell stack make it ideal for applications demanding immediate power.

4.9

out of

5

The stack's compatibility with other energy sources allows for efficient utilization and storage of various energy forms.

4.7

out of

5

The fuel cell stack's efficiency, environmental friendliness, and reliability make it an excellent choice for sustainable energy solutions.

4.8

out of

5

The stack's compact design and low weight make it suitable for various applications, including portable power supplies and drones.

4.9

out of

5

The stack's ability to generate electricity from hydrogen and oxygen makes it a promising technology for zero-emission applications.

4.7

out of

5

The fuel cell stack's modular design allows for easy scalability, enabling customization to meet different power requirements.

4.8

out of

5

The stack's durability and long lifespan make it a cost-effective investment for long-term energy needs.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Battery Lab Equipment Battery Capacity and Comprehensive Tester

The scope of application of the battery comprehensive tester can be tested: 18650 and other cylindrical, square lithium batteries, polymer batteries, nickel-cadmium batteries, nickel-metal hydride batteries, lead-acid batteries, etc.

Battery Lab Equipment 304 Stainless Steel Strip Foil 20um Thick for Battery Test

304 is a versatile stainless steel, which is widely used in the production of equipment and parts that require good overall performance (corrosion resistance and formability).

Cylindrical Lab Electric Heating Press Mold for Laboratory Applications

Efficiently prepare samples with Cylindrical Lab Electric Heating Press Mold. Fast heating, high temp & easy operation. Custom sizes available. Perfect for battery, ceramic & biochemical research.

Button Battery Case for Battery Lab Applications

Button batteries are also known as micro batteries. It looks like a small button-shaped battery. Usually larger in diameter and thinner in thickness.

Button Battery Case Gasket for Battery Lab Applications

The gasket prevents the deformation of the internal material, and the spring sheet is conducive to the tight contact inside the battery to prevent loosening.

Laboratory Hydraulic Press Lab Pellet Press for Button Battery

Efficiently prepare samples with our 2T Button Battery Press. Ideal for material research labs and small-scale production. Small footprint, lightweight, and vacuum-compatible.

Laboratory Benchtop Water Circulating Vacuum Pump for Lab Use

Need a water circulating vacuum pump for your lab or small-scale industry? Our Benchtop Water Circulating Vacuum Pump is perfect for evaporation, distillation, crystallization, and more.

Cylindrical Battery Steel Case for Battery Lab

Lithium-ion battery casing suppresses battery polarization, reduces thermal effects, and improves rate performance.

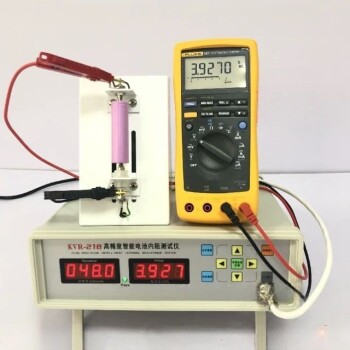

Internal Battery Resistance Tester

The main function of the battery internal resistance tester is to test the charging function, discharging function, internal resistance, voltage, protection function, capacity, overcurrent, and short circuit protection time.

Platinum Sheet Electrode for Battery Lab Applications

Platinum sheet is composed of platinum, which is also one of the refractory metals. It is soft and can be forged, rolled and drawn into rod, wire, plate, tube and wire.

Button Battery Storage Box for Battery Lab

Button-type battery storage box, detachable, high-quality PP environmental protection material; suitable for small objects/chemicals, etc., thickened, compressive, durable, and available in a variety of styles.

High Purity Zinc Foil for Battery Lab Applications

There are very few harmful impurities in the chemical composition of zinc foil, and the surface of the product is straight and smooth; it has good comprehensive properties, processability, electroplating colorability, oxidation resistance and corrosion resistance, etc.

Hydrophilic Carbon Paper TGPH060 for Battery Lab Applications

Toray carbon paper is a porous C/C composite material product (composite material of carbon fiber and carbon) that has undergone high-temperature heat treatment.

Button Battery Disassembly and Sealing Mold for Lab Use

The simple sealing and disassembly mold can be directly used on ordinary tablet presses, which can save costs, is convenient and fast, and can be used to encapsulate and disassemble button batteries. Other specifications can be customized.

Related Articles

Understanding Electrolytic Cells: Conversion of Energy and Applications

Electrochemical cell An electrochemical cell is a device capable of either generating electrical energy from chemical reactions or facilitating chemical reactions through the introduction of electrical energy.

Benefits of Electrochemical Cells for Energy Storage

Electrochemical cells are devices that convert chemical energy into electrical energy through the use of oxidation-reduction reactions. They are widely used in various applications such as energy storage, fuel cells, and batteries.

Electrochemical Cells: Generating Electricity and Driving Reactions

Electrochemical cells, like batteries, play a vital role in energy storage by converting chemical energy to electrical energy and vice versa. Explore the workings, types, and significance of these cells.

Electrochemistry The Science Behind Electrochemical Cells

Electrochemistry is important because it helps us understand the behavior of materials and substances in different environments.

Overcoming Challenges with H-Type Electrolytic Cell Operation

Understanding the components and operation of the H-type electrolytic cell is crucial in producing high-quality chemicals and overcoming the challenges that come with its operation.

Electrolytic Batteries A Solution to the Growing Energy Demands

The design of electrolytes remains a challenge, but automated discovery and the power of AI are promising tools for advancing this field.

Advanced Electrolytic Cell Techniques for Cutting-Edge Lab Research

Electrolytic cells are devices that utilize an electric current to induce a non-spontaneous chemical reaction.

Biomass Pyrolysis An Effective Means of Producing Biofuels

Biomass pyrolysis is a process that involves heating organic matter in the absence of oxygen to break it down into smaller molecules. This technology has gained popularity due to its potential to produce biofuels.

Innovations in Electrochemical Electrodes Technology

Recent advancements in nanotechnology and materials science have led to significant improvements in electrochemical devices, making them more efficient, durable, and cost-effective.

How Biomass Pyrolysis Can Help Meet Growing Energy Demands

Biomass pyrolysis is a process that converts organic material into energy-rich biofuels through heating in the absence of oxygen. This renewable energy source is becoming increasingly popular due to its environmental and economic benefits.

markdown to html 用

Biomass Pyrolysis Equipment A Sustainable Solution for Waste Management

Biomass pyrolysis has gained increased attention as a sustainable solution for waste management and renewable energy generation.