Introduction

Biomass pyrolysis is a process that converts organic material into energy-rich biofuels through heating in the absence of oxygen. This renewable energy source is becoming increasingly popular due to its environmental and economic benefits. Biomass pyrolysis has been around for centuries, but recent advancements in technology have made it more efficient and cost-effective. With the growing demand for energy and the need to reduce greenhouse gas emissions, biomass pyrolysis is emerging as a promising solution. In this blog post, we will explore the pros and cons of biomass pyrolysis, the different types of energy from biomass, the pyrolysis process stages, and the environmental and economic benefits of this renewable energy source.

Table of Contents

What is Biomass Pyrolysis?

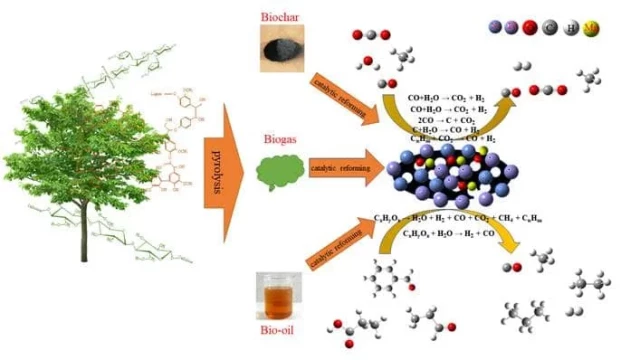

Biomass pyrolysis is a thermal process that involves heating biomass materials such as wood, agricultural residues, and municipal wastes in the absence of oxygen to produce useful products such as biochar, bio-oil, and syngas. The process occurs at high temperatures of around 500-600 degrees Celsius and under specific conditions.

The Process of Biomass Pyrolysis

The process of biomass pyrolysis involves the thermal decomposition of biomass in the absence of oxygen, which produces a range of valuable products. The process can be categorized into three types, namely, fast, slow, and intermediate pyrolysis, depending on the heating rate and temperature.

Slow Pyrolysis

Slow pyrolysis involves heating biomass at low temperatures of around 300-500 degrees Celsius for a long duration of several hours. The slow heating rate ensures that the biomass is thoroughly decomposed, resulting in high-quality charcoal or biochar as a product.

Fast Pyrolysis

Fast pyrolysis involves heating biomass at high temperatures ranging from 500-800 degrees Celsius for a shorter duration of a few seconds to minutes. The fast heating rate ensures that the biomass is rapidly decomposed, resulting in the production of a high yield of liquid bio-oil as the primary product.

Intermediate Pyrolysis

Intermediate pyrolysis occurs at temperatures ranging from 350-500 degrees Celsius and has a shorter residence time than slow pyrolysis but longer than fast pyrolysis. It results in the production of bio-oil, biochar, and syngas in almost equal proportions.

Benefits of Biomass Pyrolysis

Biomass pyrolysis is a promising technology that offers many benefits, including:

- Production of valuable products such as biochar, bio-oil, and syngas

- Production of renewable energy

- Ability to convert a wide range of biomass feedstocks

- Reduction of greenhouse gas emissions compared to fossil fuels

- Potential for carbon sequestration through the production of biochar

Challenges of Biomass Pyrolysis

Despite the many benefits of biomass pyrolysis, there are still some challenges to overcome, including:

- High capital and operating costs

- Technical challenges in scaling up the process

- Potential for emissions of pollutants such as particulate matter and volatile organic compounds

- Need for further research and development to improve process efficiency and product yields.

Conclusion

In conclusion, biomass pyrolysis is a promising technology that has the potential to provide a sustainable and carbon-neutral source of energy and materials. The process involves heating biomass in the absence of oxygen to produce a range of valuable products such as biochar, bio-oil, and syngas. While there are challenges to overcome, the benefits of biomass pyrolysis make it a promising solution to meet the growing energy demands while reducing environmental impact.

Pros of Biomass Pyrolysis

Biomass pyrolysis is a promising process that offers numerous benefits over traditional fossil fuel combustion. Here are some of the pros of biomass pyrolysis:

High Energy Efficiency

Biomass pyrolysis is a highly efficient process that can convert a large portion of the feedstock into usable energy. This means that less biomass is needed to produce the same amount of energy compared to traditional combustion methods.

Production of Valuable By-Products

The pyrolysis process can produce valuable by-products such as bio-oil, biochar, and syngas. These by-products can be used as fuel, fertilizer, or in other industrial applications, making the process more economically viable.

Low Emissions

Biomass pyrolysis produces significantly lower emissions compared to traditional fossil fuel combustion. This means that it can help reduce greenhouse gas emissions and air pollution.

Carbon Neutral

Biomass is a renewable resource, and pyrolysis does not release more CO2 than the biomass absorbed during growth, making the process carbon neutral. This means that it can help mitigate climate change and reduce our dependence on fossil fuels.

Flexibility

Biomass pyrolysis can be adapted to work with a variety of feedstocks, making it a versatile option for different regions and industries. This means that it can help reduce waste and generate energy from a wide range of sources.

Reduced Dependence on Fossil Fuels

By using biomass instead of fossil fuels, biomass pyrolysis can help reduce our dependence on non-renewable resources. This means that it can help promote energy security and reduce our reliance on foreign oil.

In conclusion, biomass pyrolysis offers a renewable and sustainable alternative to traditional fossil fuel combustion. It is a highly efficient process that can produce valuable by-products while reducing emissions and our dependence on non-renewable resources. As the demand for energy continues to grow, biomass pyrolysis can help meet this demand in an environmentally friendly way.

The History of Biomass Pyrolysis

Biomass pyrolysis is a process that has been used for thousands of years, and its history can be traced back to ancient civilizations. The first known use of pyrolysis was the production of charcoal through the incomplete combustion of wood. Charcoal was used for cooking, heating, and as a fuel for industrial purposes.

In the 19th century, the concept of pyrolysis was introduced in the field of chemistry, and it was later applied to the production of charcoal for industrial purposes. The development of new technologies allowed the production of larger quantities of charcoal, which was a valuable fuel source for the growing industrial economy.

In the 20th century, the potential of pyrolysis for the production of biofuels was explored, and today, it is a promising technology for the conversion of biomass into renewable energy. The modern biomass pyrolysis process involves the thermal decomposition of organic materials in the absence of oxygen, which results in the production of biochar, bio-oil, and gases.

The pyrolysis process has three stages: dosing and feeding of the raw material, transformation of the organic mass, and obtaining and separation of the products (coke, bio-oil, and gas). The factors that influence the distribution of the products are the heating rate, final temperature, composition of the raw material, and pressure.

Today, biomass pyrolysis has several advantages over other forms of renewable energy, such as solar and wind, as it can be used to produce energy continuously without being dependent on weather conditions. It also has the potential to reduce greenhouse gas emissions by replacing fossil fuels. However, there are also challenges associated with the commercialization of biomass pyrolysis, such as high capital costs and the need for further research to improve the efficiency of the process.

Overall, the history of biomass pyrolysis highlights its potential as a sustainable and renewable energy source that can help meet growing energy demands. With further advancements in technology and research, biomass pyrolysis has the potential to become a significant contributor to the world's energy mix.

Biomass as a Promising Energy Source

Biomass is a promising energy source that has the potential to meet the world's growing energy demands while reducing greenhouse gas emissions. It is a renewable resource that includes organic matter such as forestry waste, agricultural waste, and municipal solid waste. These materials have traditionally been considered waste and are often discarded, but they can be converted into valuable products through biomass pyrolysis.

Advantages of Biomass

Biomass has several advantages over fossil fuels. First, it is a renewable resource that can be continually replenished. Second, it can help reduce greenhouse gas emissions by replacing fossil fuels. Third, it can be produced locally, reducing dependence on foreign oil. Fourth, it does not produce toxic emissions, making it a cleaner and safer energy source. Finally, it can be used to produce a range of valuable products, such as biochar, bio-oil, and gas, making it a more efficient and sustainable method of energy production.

Biomass Pyrolysis

Biomass pyrolysis is a promising method of generating energy from organic matter. The process involves heating the biomass in the absence of oxygen to produce biochar, bio-oil, and gas. Biochar is a stable form of carbon that can be used as a soil amendment to improve soil fertility and carbon sequestration. Bio-oil is a liquid fuel that can be used in engines and turbines, while gas can be used for heating or electricity generation. The advantage of biomass pyrolysis is that it can produce a range of valuable products from a single feedstock, making it a more efficient and sustainable method of energy production.

Types of Biomass

Lignocellulosic biomass is the most abundant renewable carbon source on Earth and includes forest residues, crop residues, purpose-grown energy crops (e.g. grasses), animal wastes, and food wastes. These materials are the fibrous structural parts of plants and are largely made of cellulose, hemicellulose, and lignin. Compared with so-called 1st generation bio-feedstocks such as sugars, starches, and vegetable oils, nature has made these parts of the plants difficult to deconstruct to chemical building blocks, making utilization of this carbon source a challenge for scientists and engineers.

Pyrolysis

Pyrolysis is one of the technologies available to convert biomass to an intermediate liquid product that can be refined to drop-in hydrocarbon biofuels, oxygenated fuel additives, and petrochemical replacements. Pyrolysis is the heating of an organic material, such as biomass, in the absence of oxygen. Biomass pyrolysis is usually conducted at or above 500 °C, providing enough heat to deconstruct the strong bio-polymers mentioned above. Because no oxygen is present, combustion does not occur, rather the biomass thermally decomposes into combustible gases and bio-char. Most of these combustible gases can be condensed into a combustible liquid, called pyrolysis oil (bio-oil), though there are some permanent gases (CO2, CO, H2, light hydrocarbons), some of which can be combusted to provide the heat for the process. Thus, pyrolysis of biomass produces three products: one liquid, bio-oil, one solid, bio-char, and one gaseous, syngas.

Conclusion

Biomass pyrolysis has great potential as a renewable energy source, and research into its various forms and applications continues to progress. By utilizing biomass as a promising energy source, we can reduce our dependence on fossil fuels, while also reducing waste and improving soil health. As technology advances, biomass pyrolysis has the potential to become an increasingly efficient and sustainable method of energy production.

Different Types of Energy from Biomass

Biomass pyrolysis is a promising technology that can convert organic materials into different types of energy. The process involves heating biomass in the absence of oxygen to produce bio-oil, bio-char, and syngas. These different types of energy have various applications and can help meet the growing energy demands.

Bio-oil

Bio-oil is a liquid fuel that can be used for heating and electricity generation. It is produced through fast pyrolysis, which involves heating biomass at high temperatures in the absence of oxygen. The resulting bio-oil is a complex mixture of organic compounds, including carboxylic acids, ketones, and aldehydes. Bio-oil can be further processed to produce biofuels such as ethanol and biodiesel.

Bio-char

Bio-char is a solid carbon-rich material that can be used as a soil amendment to improve soil fertility and reduce greenhouse gas emissions. It is produced through slow pyrolysis, which involves heating biomass at lower temperatures and longer residence times. The resulting bio-char has a high carbon content and can sequester carbon for a long period of time, making it a useful tool for carbon sequestration.

Syngas

Syngas is a mixture of hydrogen, carbon monoxide, and other gases that can be used as a fuel for power generation or as a feedstock for the production of chemicals and fuels. It is produced through slow pyrolysis and gasification, which involve heating biomass in the presence of controlled amounts of oxygen and/or steam. The resulting syngas can be treated to separate the hydrogen from the gas, and the hydrogen can be burned or used in fuel cells. The syngas can also be further processed to produce liquid fuels using the Fischer–Tropsch process.

In addition to these three main types of energy, there are other products that can be produced through biomass pyrolysis. Tar and wood vinegar are collected separately, and biogas can be collected into a tank or used to heat the chamber directly.

Biomass pyrolysis offers a promising solution to meet the growing energy demands while reducing greenhouse gas emissions and promoting sustainable development. Different types of energy from biomass can be produced through various pyrolysis technologies such as fast pyrolysis, slow pyrolysis, and gasification. The choice of technology will depend on the desired end products and the feedstock used. Bio-oil is more suitable for the production of biofuels, while bio-char is more suitable for the production of soil amendment. Syngas has a wide range of applications and can be used to produce chemicals and fuels.

Pyrolysis Process Stages

The biomass pyrolysis process can be divided into three main stages, namely drying, pyrolysis, and char formation.

Drying Stage

During the drying stage, the moisture content of the biomass is reduced to less than 10%. This is done to prevent steam generation during the pyrolysis stage. Moisture content is an important factor that affects the quality and yield of the pyrolysis products. The drying process can be done using different methods, such as air drying, sun drying, or mechanical drying.

Pyrolysis Stage

In the pyrolysis stage, the biomass is heated to a temperature of 400-600°C in the absence of oxygen. This causes the biomass to break down into its constituent parts. The pyrolysis process can be classified into two types, namely slow pyrolysis and fast pyrolysis.

Slow pyrolysis is a process that involves heating the biomass at a low heating rate of around 5-7°C/min. This process produces minimal liquid and gaseous products, and maximizes the production of coal. Fast pyrolysis, on the other hand, involves heating the biomass at a high heating rate of around 100-1000°C/s. This process produces mainly vapors and aerosols, and a small amount of coal and gas.

Char Formation Stage

In the char formation stage, the remaining biomass is converted into char. The char is a solid carbon-rich material that can be used as a soil amendment or activated carbon. During this process, water or incondensable gas is also released. Char formation can be done using different types of reactors, such as fixed-bed reactors, fluidized-bed reactors, and entrained-flow reactors.

The quality and yield of the pyrolysis products depend on various factors such as the type of biomass used, the pyrolysis conditions, and the reactor design. The primary mechanism of the pyrolysis process involves volatile compounds released during biomass heating, while the secondary mechanism involves the further reaction of these compounds.

In conclusion, the biomass pyrolysis process involves three stages, namely drying, pyrolysis, and char formation. Each stage is crucial to the overall quality and yield of the pyrolysis products. Understanding the pyrolysis process and its stages is essential for optimizing the process for different types of biomass and applications.

Environmental and Economic Benefits

Biomass pyrolysis is an innovative technology that offers several environmental and economic benefits. This process involves heating organic matter in the absence of oxygen, which results in the breakdown of organic material into a solid form of carbon known as biochar.

Reduced Greenhouse Gas Emissions

One of the most significant benefits of biomass pyrolysis is its ability to reduce greenhouse gas emissions. Biochar produced through the process is a stable form of carbon that can remain in the soil for hundreds or thousands of years, effectively sequestering carbon and reducing the amount of carbon dioxide released into the atmosphere.

Improved Soil Fertility

Biochar produced through biomass pyrolysis can also be used to improve soil fertility. When added to soil, biochar can increase water retention, enhance nutrient retention, and improve soil structure. These benefits can lead to increased agricultural yields and reduce the need for synthetic fertilizers.

Job Creation in Rural Areas

Biomass pyrolysis can provide an economic stimulus to rural areas. Locations with an existing forestry industry are particularly attractive as they offer a reliable source of feed within a close radius of a potential plant location. Additionally, the pyrolysis plants provide an opportunity for local power generation for areas without the grid infrastructure to support centralized power production.

Reduced Landfill Waste

Biomass pyrolysis can also help reduce waste that is sent to landfills. The process can convert organic waste materials, such as plastics, rubber, and biomass, into valuable products, including biofuels, chemicals, and other substances. This can help to reduce the environmental impact of these materials and can also provide an economic benefit by reducing the need for virgin raw materials.

Energy Efficiency and Flexibility

Pyrolysis is an energy-efficient process, and its furnaces can be used to process a wide range of organic materials, making them a flexible tool for a variety of applications. The energy required to heat the furnace is typically offset by the energy produced in the form of biofuels or other valuable products. Furthermore, pyrolysis can be used to recover valuable materials, such as plastics and rubber, from waste streams.

In conclusion, biomass pyrolysis offers several environmental and economic benefits, including reduced greenhouse gas emissions, improved soil fertility, job creation in rural areas, reduced landfill waste, energy efficiency, and flexibility. These benefits make it an exciting area of study and innovation in the field of laboratory equipment.

Conclusion

In conclusion, biomass pyrolysis is a promising method for meeting the world's growing energy demands. While it has its drawbacks, such as high initial costs and the potential release of harmful emissions, the benefits of producing renewable energy and reducing waste outweigh the negatives. The pyrolysis process can produce various types of energy, including biochar, bio-oil, and syngas, which are valuable resources for industries and households. Additionally, biomass pyrolysis can have significant environmental and economic benefits, such as reducing greenhouse gas emissions and creating job opportunities. As a result, it is crucial to continue investing in and researching this technology to achieve a sustainable future.

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Laboratory Manual Hydraulic Pellet Press for Lab Use

Related Articles

- Rotary Furnaces: A Comprehensive Guide to Advanced Materials Processing

- The Advantages and Disadvantages of Different Biomass Feedstocks for Pyrolysis

- Electric Rotary Kiln Pyrolysis Furnace: A Comprehensive Guide to Pyrolysis Technology

- How Biomass Pyrolysis Machines Work A Comprehensive Overview

- Electric Rotary Kiln Pyrolysis Furnace: Design, Operation, and Applications