battery material

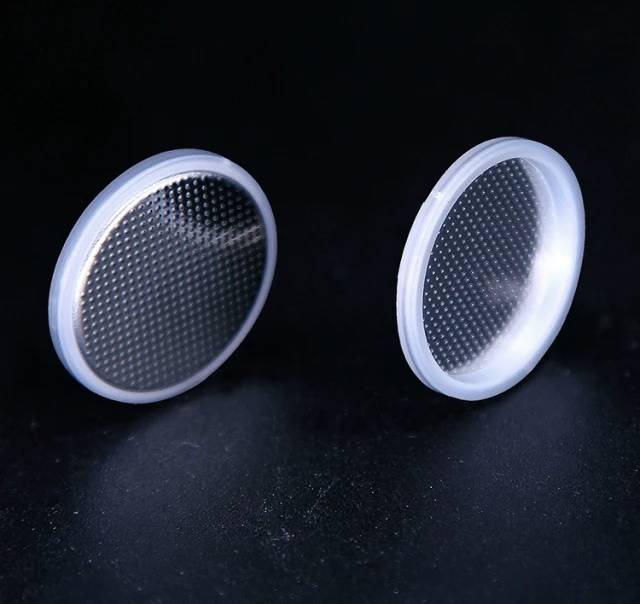

Button Battery Case for Battery Lab Applications

Item Number : BC-01

Price varies based on specs and customizations

- Material

- 304 stainless steel

- Size

- Diameter 20mm thick 3.2mm

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Introduce

The shell of the micro-battery is a protective layer that protects the internal materials of the battery and increases the strength of the shell, and plays the role of reducing vibration, heat, shock, moisture and corrosion of the battery, preventing liquid leakage, and preventing dust.

Button batteries are also known as micro batteries. It looks like a small button-shaped battery. Usually larger in diameter and thinner in thickness. It consists of positive electrode sheet, negative electrode sheet, separator and electrolyte.

The button battery case is an important part of it. Button battery casings are mostly made of stainless steel and aluminum. There is an insulating ring between the positive and negative shells to insulate and prevent electrolyte leakage.

Button batteries are widely used in various miniature digital electronic products due to their small size, diameters from 4.8mm to 30mm, and thicknesses from 1.0mm to 7.7mm. , such as computer motherboards, electronic watches, electronic dictionaries, electronic scales, remote controls, electric toys, pacemakers, electronic hearing aids, counters, cameras, etc.

Detail & Parts

Trusted by Industry Leaders

FAQ

What Considerations Should Be Made For Battery Case Gaskets?

About Button Batteries.

What Is The Role Of Battery Case Gaskets?

What Are Lithium-air Battery Cases?

How Should Button Battery Cases Be Chosen For Specific Applications?

4.9 / 5

I was so impressed with the durability of the button battery case. It's made of high-quality materials and has held up well to everyday use.

4.7 / 5

The button battery case's quality is impeccable. It's well-made and sturdy, providing excellent protection for my batteries.

4.8 / 5

This button battery case is a great value for the money. It's affordable and does exactly what it's supposed to do.

5.0 / 5

I'm thoroughly impressed with the technological advancement of this button battery case. It's innovative and makes battery storage and organization a breeze.

4.7 / 5

The speed of delivery for the button battery case was exceptional. I received it within a few days of placing my order.

4.9 / 5

I'm amazed by the durability of the button battery case. It's built to last and has endured various conditions without any signs of wear.

5.0 / 5

The button battery case is a fantastic investment. It's well-made, reliable, and offers exceptional protection for my batteries.

4.8 / 5

I'm genuinely impressed with the quality of the button battery case. It's sturdy, durable, and effectively safeguards my batteries.

4.9 / 5

The button battery case is a smart purchase. It's affordable, yet delivers exceptional quality and protection for my batteries.

5.0 / 5

I'm thrilled with the technological advancement of the button battery case. It's innovative and simplifies battery storage and organization.

4.7 / 5

The durability of the button battery case is remarkable. It's built to withstand everyday use and has held up perfectly.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Button Battery Case Gasket for Battery Lab Applications

The gasket prevents the deformation of the internal material, and the spring sheet is conducive to the tight contact inside the battery to prevent loosening.

Button Battery Storage Box for Battery Lab

Button-type battery storage box, detachable, high-quality PP environmental protection material; suitable for small objects/chemicals, etc., thickened, compressive, durable, and available in a variety of styles.

Button Battery Tablet Press Sealing Mold for Lab Use

The sealing die is essential for assembling button batteries, ensuring components like the anode, cathode, and electrolyte are securely enclosed.

Laboratory Hydraulic Press Lab Pellet Press for Button Battery

Efficiently prepare samples with our 2T Button Battery Press. Ideal for material research labs and small-scale production. Small footprint, lightweight, and vacuum-compatible.

Button Battery Disassembly and Sealing Mold for Lab Use

The simple sealing and disassembly mold can be directly used on ordinary tablet presses, which can save costs, is convenient and fast, and can be used to encapsulate and disassemble button batteries. Other specifications can be customized.

Cylindrical Battery Steel Case for Battery Lab

Lithium-ion battery casing suppresses battery polarization, reduces thermal effects, and improves rate performance.

Lithium Battery Tab Tape for Battery Lab Applications

PI polyimide tape, generally brown, also known as gold finger tape, high temperature resistance 280 ℃, to prevent the influence of heat sealing of soft pack battery lug glue, suitable for soft pack battery tab position glue.

Battery Lab Equipment 304 Stainless Steel Strip Foil 20um Thick for Battery Test

304 is a versatile stainless steel, which is widely used in the production of equipment and parts that require good overall performance (corrosion resistance and formability).

Battery Lab Equipment Battery Capacity and Comprehensive Tester

The scope of application of the battery comprehensive tester can be tested: 18650 and other cylindrical, square lithium batteries, polymer batteries, nickel-cadmium batteries, nickel-metal hydride batteries, lead-acid batteries, etc.

Platinum Sheet Electrode for Battery Lab Applications

Platinum sheet is composed of platinum, which is also one of the refractory metals. It is soft and can be forged, rolled and drawn into rod, wire, plate, tube and wire.

Cylindrical Lab Electric Heating Press Mold for Laboratory Applications

Efficiently prepare samples with Cylindrical Lab Electric Heating Press Mold. Fast heating, high temp & easy operation. Custom sizes available. Perfect for battery, ceramic & biochemical research.

High Purity Zinc Foil for Battery Lab Applications

There are very few harmful impurities in the chemical composition of zinc foil, and the surface of the product is straight and smooth; it has good comprehensive properties, processability, electroplating colorability, oxidation resistance and corrosion resistance, etc.

Hydrophilic Carbon Paper TGPH060 for Battery Lab Applications

Toray carbon paper is a porous C/C composite material product (composite material of carbon fiber and carbon) that has undergone high-temperature heat treatment.

Assemble Square Lab Press Mold for Laboratory Applications

Achieve perfect sample preparation with Assemble Square Lab Press Mold. Quick disassembly eliminates sample deformation. Perfect for battery, cement, ceramics, and more. Customizable sizes available.

Nickel Aluminum Tabs for Soft Pack Lithium Batteries

Nickel tabs are used to manufacture cylindrical and pouch batteries, and positive aluminum and negative nickel are used to produce lithium-ion and nickel batteries.

Related Articles

Battery sealing machine operating steps and precautions

Introduction to the operating steps and precautions of the battery sealing machine

Electrolytic Batteries A Solution to the Growing Energy Demands

The design of electrolytes remains a challenge, but automated discovery and the power of AI are promising tools for advancing this field.

Advanced Electrolytic Cell Techniques for Cutting-Edge Lab Research

Electrolytic cells are devices that utilize an electric current to induce a non-spontaneous chemical reaction.

The Invisible Variable: Why Electrolytic Cell Hygiene Defines Your Data

Proper electrolytic cell maintenance prevents dangerous reactions and ensures data integrity. Learn the critical "no metal brush" rule and safety protocols.

The Architecture of Silence: Why Quartz Defines Electrochemical Precision

In electrochemistry, the vessel is as critical as the catalyst. Discover why quartz's unique properties make it the unseen hero of precise experimentation.