Molds & Accessories

Button Battery Tablet Press Sealing Mold for Lab Use

Item Number : PMN

Price varies based on specs and customizations

- Dual-purpose mold

- Sealing, opening and dual-use

- Sealing pressure

- 0.8-1.2 Ton

- Dismantling pressure

- <0.4 Ton

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Introduction

The sealing die is essential for assembling button batteries, ensuring components like the anode, cathode, and electrolyte are securely enclosed. It enhances battery safety and reliability by protecting internal materials from external factors.

Application

Functioning as a precise mold, the sealing die compresses and seals button battery components with high pressure and temperature resistance. Made from durable materials like hardened steel, it ensures consistent, high-quality assembly, crucial for maintaining battery performance and safety in electronic devices.

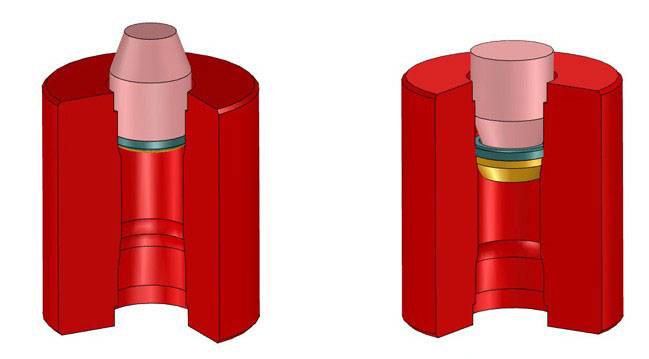

Detail & Parts

Technical specifications

| Instrument model | PMN |

| Dual-purpose mold | Sealing, opening and dual-use |

| Sealing function | CR16,CR20,CR24,CR30 optional |

| Sealing pressure | 0.8-1.2 Ton |

| Dismantling function | CR16,CR20,CR24,CR30 optional |

| Dismantling pressure | |

| Diagram of hydraulic powder press size |  |

Operation steps

1.Assemble the case of the button cell.

2.Put the assembled button cell in the hole in the packing die.

3.Put on the flat punch.

4.Put the die in the hydraulic press.

5.Increase the pressure to about 1000kg.

6.Take out the packed button cell.

7.To disassemble the button cell, first put the assembled button cell in the hole of the die marked with disassembly.

8.Put on the tapered punch.

9.Increase the pressure to about 400 kg.

10.Take out the disassembled button cell.

Trusted by Industry Leaders

FAQ

What Considerations Should Be Made For Battery Case Gaskets?

What Is A Press Mold?

What Is The Role Of Battery Case Gaskets?

What Is Press Mould In Ceramics?

What Are Lithium-air Battery Cases?

How Are Pellet Molds Used?

How Should Button Battery Cases Be Chosen For Specific Applications?

What Types Of Materials Can Be Pelletized Using Pellet Molds?

How Can One Select The Appropriate Pellet Mold For Their Specific Application?

4.7 / 5

Exceptional quality and durability. A must-have for our lab!

4.8 / 5

Incredible value for money. Streamlined our battery production.

4.9 / 5

Fast delivery and top-notch technology. Highly recommend!

4.7 / 5

Revolutionized our battery assembly process. Very satisfied!

4.8 / 5

Reliable and efficient. A game-changer for our lab work.

4.9 / 5

Outstanding performance. Our battery quality has improved immensely.

4.7 / 5

User-friendly and robust. Perfect for our research needs.

4.8 / 5

Excellent support and quick delivery. Very pleased with the purchase.

4.9 / 5

Advanced technology at its best. Our lab efficiency has soared.

4.7 / 5

Durable and precise. A key asset to our battery production.

4.8 / 5

Highly recommend for any lab. Our battery press runs flawlessly.

4.9 / 5

Superior quality and service. Our lab couldn't be happier.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Button Battery Disassembly and Sealing Mold for Lab Use

The simple sealing and disassembly mold can be directly used on ordinary tablet presses, which can save costs, is convenient and fast, and can be used to encapsulate and disassemble button batteries. Other specifications can be customized.

Laboratory Hydraulic Press Lab Pellet Press for Button Battery

Efficiently prepare samples with our 2T Button Battery Press. Ideal for material research labs and small-scale production. Small footprint, lightweight, and vacuum-compatible.

Button Battery Case for Battery Lab Applications

Button batteries are also known as micro batteries. It looks like a small button-shaped battery. Usually larger in diameter and thinner in thickness.

Assemble Square Lab Press Mold for Laboratory Applications

Achieve perfect sample preparation with Assemble Square Lab Press Mold. Quick disassembly eliminates sample deformation. Perfect for battery, cement, ceramics, and more. Customizable sizes available.

Button Battery Case Gasket for Battery Lab Applications

The gasket prevents the deformation of the internal material, and the spring sheet is conducive to the tight contact inside the battery to prevent loosening.

Cylindrical Lab Electric Heating Press Mold for Laboratory Applications

Efficiently prepare samples with Cylindrical Lab Electric Heating Press Mold. Fast heating, high temp & easy operation. Custom sizes available. Perfect for battery, ceramic & biochemical research.

Multi-Punch Rotary Tablet Press Mold Ring for Rotating Oval and Square Molds

The multi-punch rotary tablet press mold stands as a pivotal component in pharmaceutical and manufacturing industries, revolutionizing the process of tablet production. This intricate mold system comprises multiple punches and dies arranged in a circular fashion, facilitating rapid and efficient tablet formation.

Button Battery Storage Box for Battery Lab

Button-type battery storage box, detachable, high-quality PP environmental protection material; suitable for small objects/chemicals, etc., thickened, compressive, durable, and available in a variety of styles.

Assemble Lab Cylindrical Press Mold

Get reliable and precise molding with Assemble Lab Cylindrical Press Mold. Perfect for ultra-fine powder or delicate samples, widely used in material research and development.

Lithium Battery Tab Tape for Battery Lab Applications

PI polyimide tape, generally brown, also known as gold finger tape, high temperature resistance 280 ℃, to prevent the influence of heat sealing of soft pack battery lug glue, suitable for soft pack battery tab position glue.

High Purity Zinc Foil for Battery Lab Applications

There are very few harmful impurities in the chemical composition of zinc foil, and the surface of the product is straight and smooth; it has good comprehensive properties, processability, electroplating colorability, oxidation resistance and corrosion resistance, etc.

Battery Lab Equipment 304 Stainless Steel Strip Foil 20um Thick for Battery Test

304 is a versatile stainless steel, which is widely used in the production of equipment and parts that require good overall performance (corrosion resistance and formability).

Hydrophilic Carbon Paper TGPH060 for Battery Lab Applications

Toray carbon paper is a porous C/C composite material product (composite material of carbon fiber and carbon) that has undergone high-temperature heat treatment.

Platinum Sheet Electrode for Battery Lab Applications

Platinum sheet is composed of platinum, which is also one of the refractory metals. It is soft and can be forged, rolled and drawn into rod, wire, plate, tube and wire.

Infrared Heating Quantitative Flat Plate Press Mold

Discover advanced infrared heating solutions with high-density insulation and precise PID control for uniform thermal performance in various applications.

Related Articles

Manual Pellet Press: A Comprehensive Guide to Efficient Lab Pelletizing

Explore the intricacies of manual pellet presses, including operation, safety, and maintenance tips. Learn how to choose the right press, understand force gauges, and optimize pellet quality for your lab experiments.

Principle and Process of Cold Isostatic Pressing

Explains the mechanism, factors, and process of cold isostatic pressing in powder molding.