Introduction to Manual Pellet Presses

Manual pellet presses are indispensable tools in laboratory settings, offering a reliable method for pelletizing materials efficiently. Unlike automated alternatives, manual presses provide a hands-on approach that can be more adaptable and cost-effective for various research applications. This guide delves into the intricacies of manual pellet presses, covering their key components, safety measures, and optimal operation techniques. By understanding the benefits and practical applications of these presses, researchers can enhance their experimental processes and achieve superior pellet quality.

Key Components and Features of Manual Pellet Presses

Manual pellet presses are essential equipment in laboratories for converting powdered materials into solid pellets, which are crucial for various analytical techniques such as X-ray diffraction and infrared spectroscopy. The effectiveness of these presses largely depends on their key components: the die, ram, and force gauge. Understanding the role and significance of each component is vital for optimizing the pelletizing process.

Die

The die is the heart of the pellet press, responsible for shaping the powdered material into cylindrical pellets. It consists of a flat, circular plate with numerous holes through which the material is forced to form pellets. The size and number of these holes determine the final size of the pellets. In laboratory settings, dies are typically made from hardened steel to withstand the high pressures involved and to ensure a long service life.

The design of the die also includes considerations for the distribution of pressure. For instance, the working length of the die, which is the distance from the entry point of the material to the exit holes, affects the density and uniformity of the pellets. A longer working length allows for more uniform compression, resulting in denser and more consistent pellets.

Ram

The ram is the component that applies pressure to the powdered material within the die. It is a cylindrical plunger that fits snugly into the die, ensuring that the force is applied evenly across the material. The ram is typically operated manually, either directly or through a lever system that amplifies the applied force, allowing even relatively low manual inputs to generate high compressive forces.

The design of the ram is critical for efficient operation. It must be precisely machined to fit the die without leaving gaps that could lead to uneven compression or material leakage. Additionally, the surface of the ram is often polished to reduce friction and ensure smooth operation.

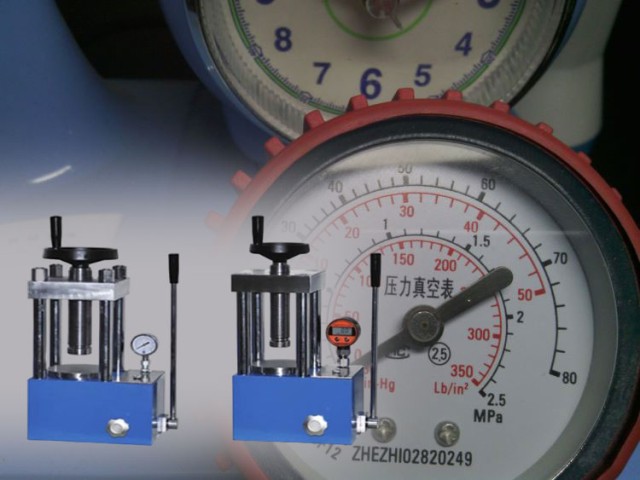

Force Gauge

The force gauge is an essential feature of manual pellet presses, providing real-time feedback on the amount of pressure being applied. This is crucial for achieving consistent results, as different materials require different levels of compression to form satisfactory pellets. The force gauge can be calibrated to display the pressure in units such as pounds per square inch (psi) or kilograms per square centimeter (kg/cm²).

In laboratory applications, the ability to monitor and adjust the applied force ensures that the pellets meet the required specifications for subsequent analyses. For example, in X-ray diffraction, the density and uniformity of the pellets can significantly affect the quality of the diffraction pattern.

Additional Features

Beyond the core components, manual pellet presses may include additional features to enhance their functionality and ease of use. For instance, some models come with adjustable anvils that allow the operator to change the height of the die relative to the ram. This feature is particularly useful when working with materials of varying densities, as it allows for fine-tuning of the compression process to achieve optimal pellet quality.

Furthermore, the design of the press may incorporate safety features such as non-slip handles and stable bases to ensure safe and ergonomic operation. These features are important for preventing accidents and reducing operator fatigue, especially during prolonged use.

In conclusion, the key components of manual pellet presses—the die, ram, and force gauge—each play a critical role in the pelletizing process. Understanding their functions and interactions allows for more effective use of these presses, ensuring the production of high-quality pellets for various analytical applications. Whether in research laboratories or quality control settings, the careful selection and operation of these components are essential for achieving reliable and reproducible results.

Safety Measures and Best Practices

Operating a manual pellet press safely is crucial to prevent accidents and ensure the quality of the pellets produced. This section will discuss the importance of safety guards, flat pressing surfaces, and understanding the difference between force and pressure gauges. By adhering to these best practices, you can maintain a safe working environment and achieve consistent results.

Importance of Safety Guards

Safety guards are an essential component of any manual pellet press. They serve as a protective barrier between the operator and the moving parts of the press, reducing the risk of injury. All hydraulic lab presses should come equipped with a Perspex safety guard, which allows for visibility while providing a physical barrier. Before operating the press, ensure that the safety guard is properly installed and in good condition.

Flat Pressing Surfaces

The quality of the pellets produced is heavily dependent on the flatness of the pressing surfaces. Dies should be polished and free from any imperfections to ensure uniform compression of the powdered material. The Pellet Press from Kintek, for example, uses a polished die to produce cylindrical pellets with flat ends. This uniformity is crucial for accurate measurements and consistent results.

Understanding Force and Pressure Gauges

One of the most critical aspects of operating a manual pellet press is understanding the difference between force and pressure gauges. Many presses come with a pressure gauge that reads in psi or MPa, which measures the pressure of the oil under the ram in the press. To convert this pressure to force, you need to divide by the effective area of the ram. This information should be available in the press manual or provided as a conversion graph or formula.

For smaller pellets, using a smaller press is recommended as it allows for more accurate force application and better control. Pressing a 6 mm die set with a 40-ton press, for example, can be challenging and may lead to errors if the force applied is not carefully monitored. Always plan ahead and know the target force before pressing to avoid exceeding the maximum force for the die set.

Step-by-Step Operation

To ensure safe and effective operation, follow these steps when using a manual pellet press:

- Fix the Pellet Press Together: Insert the die into the cavity and ensure it is properly aligned.

- Transfer the Sample: Use a metal spatula to evenly spread the ground sample mix into the cavity. The amount of powder should be based on the desired pellet thickness.

- Insert the Bolt Press: Rotate the bolt press into the cavity to distribute the particles evenly.

- Secure the Die Set: Transfer the die set to the hydraulic pellet press and rotate the wheel to secure it tightly.

- Apply Pressure: Close the valve of the hydraulic press and pull the level to apply pressure until the handle becomes tight.

- Release the Die: To remove the die, first loosen the pressure, then move up the upper wheel of the press, and finally take out the die.

By following these safety measures and best practices, you can operate a manual pellet press safely and efficiently. Always prioritize safety, ensure the flatness of pressing surfaces, and understand the relationship between force and pressure to achieve consistent and high-quality results.

Selecting the Right Manual Pellet Press

Choosing the right manual pellet press is crucial for ensuring accurate and safe operations in your laboratory. This decision should be based on several key factors, including the size of the pellets, the required force capacity, and the availability of safety and monitoring features. Here’s a detailed guide to help you select the best manual pellet press for your specific needs.

Understanding Pellet Size and Press Compatibility

The diameter of the pellets you intend to produce is a primary consideration. For smaller pellets, typically less than 8 mm in diameter, a smaller press is recommended. These smaller presses allow for more precise control over the force applied, enhancing the accuracy and quality of the pellets. Conversely, using a large press for smaller die sets can lead to over-compression, where a single pump of the handle might exceed the maximum safe force for the die, leading to errors and potential damage.

Force Capacity and Safety

The force capacity of the press is another critical factor. It’s essential to choose a press that can comfortably handle the force required for your specific applications. For instance, a manual hydraulic pellet press with a variable pressure force up to 250 kN is suitable for a wide range of applications, from small to large pellets. These presses often come with a clearly designed pressure force display, which is crucial for maintaining control and safety during operations.

Safety features are non-negotiable when selecting a manual pellet press. All hydraulic lab presses should include a Perspex safety guard and a pressure gauge. These features not only protect the operator but also ensure that the force applied is accurately monitored and controlled. The safety guard prevents accidental contact with moving parts, while the pressure gauge provides real-time feedback on the force being applied.

Operational Efficiency and Ease of Use

Ease of operation is another significant factor. Manual hydraulic presses that feature simple operation via a hand lever are preferred, as they reduce the physical strain on the operator and enhance operational efficiency. Additionally, presses that are easy to clean and maintain are more practical for laboratory settings where hygiene and continuity of service are paramount.

Customization and Adaptability

For laboratories that require longer pellets, it’s important to consider the potential for higher buckling stresses in the plunger. In such cases, reducing the force, decreasing the pellet height, or using a shorter plunger can mitigate these stresses. Custom plungers are available for purchase, offering flexibility in adapting the press to specific needs.

Conclusion

In summary, selecting the right manual pellet press involves careful consideration of pellet size, force capacity, safety features, ease of operation, and adaptability. By focusing on these factors, you can ensure that your laboratory has the right equipment to produce high-quality pellets efficiently and safely. Always ensure that the press you choose includes essential safety and monitoring features, such as a safety guard and a pressure gauge, to protect both your equipment and your operators.

Step-by-Step Guide to Operating a Manual Pellet Press

Operating a manual pellet press involves a series of precise steps to ensure the production of high-quality pellets from powdered materials. This guide will walk you through the setup, operation, and troubleshooting of a manual pellet press, ensuring you achieve consistent and reliable results.

Setup and Preparation

-

Workspace Safety: Begin by ensuring your workspace is clean and free of obstructions. This is crucial for safe and efficient operation. Clear the area around the press to prevent any accidental interference during the pressing process.

-

Die Placement: Place the pellet die, containing your sample material, centrally on the piston. Ensure the die is aligned properly to avoid any misalignment during the pressing process.

-

Material Quantity: The amount of material you load into the die should be carefully measured. Generally, the height of the pellet should not greatly exceed its diameter to prevent cracking or other adverse effects. If pressing longer pellets, consider using lower forces and possibly lubricating the die.

-

Assembly of the Press: Fix the pellet press together by inserting the die into the cavity. Ensure all components are securely in place before proceeding.

Operation

-

Loading the Sample: Transfer the ground sample mix into the cavity using a metal spatula. Ensure the sample is evenly spread to achieve uniform pellets. The thickness of the pellet will depend on the amount of powder used.

-

Distributing the Particles: Insert the bolt press and rotate it into the cavity to distribute the particles evenly. This step is crucial for uniform compression.

-

Securing the Die: Transfer the whole die set to the hydraulic pellet press and rotate the wheel to secure it tightly. This ensures the die remains stable during the pressing process.

-

Applying Pressure: Close the valve of the hydraulic press. Pull the level to apply pressure until the handle becomes tight. The pressure should be applied gradually to avoid any sudden force that could damage the pellets.

-

Releasing the Die: To release the die, first, loosen the pressure by reversing the pump action. Then, move the upper wheel of the press to disengage the die. Carefully remove the die to retrieve the pellets.

Troubleshooting Common Issues

-

Cracking or Adverse Effects: If pellets are cracking or showing other adverse effects, consider adjusting the amount of material or the pressure applied. Overloading the die or applying excessive pressure can lead to these issues.

-

Non-Uniform Pellets: If the pellets are not uniform in shape or size, check the alignment of the die and ensure the sample is evenly spread before pressing. Misalignment or uneven distribution can cause variations in the final product.

-

Difficulty in Ejection: If the pellets are difficult to eject, ensure the die is properly lubricated. Lubrication helps in smooth ejection and prevents sticking.

By following these detailed steps and troubleshooting tips, you can effectively operate a manual pellet press to produce high-quality pellets for your laboratory needs. Remember to always prioritize safety and precision to achieve the best results.

Maintenance and Care for Longevity

To ensure the longevity and consistent performance of your manual pellet press, it is crucial to follow a comprehensive maintenance and care routine. This includes regular cleaning, proper storage, and periodic check-ups. Here are detailed best practices to help you maintain your pellet press effectively.

Cleaning Procedures

1. Daily Cleaning:

- After Each Use: Immediately after using the pellet press, clean the die and roller shells thoroughly. Use a soft brush or compressed air to remove any residual pellets or dust. Ensure that the inside diameter of the die and the outside diameter of the roll shells are free from debris.

- Gap Adjustment: Regularly adjust the gap between the die and roller shells. This involves shutting down the pellet mill, cleaning the eccentric shafts, clamps, bolts, and surfaces, and ensuring no feed or dust remains between the rolls and the die. Use a visiting card or paper folds (~0.5 mm) to set the gap correctly.

2. Weekly Cleaning:

- Deep Cleaning: Once a week, disassemble the press and clean all components thoroughly. Use a mild solvent to remove any stubborn residues. Pay special attention to the hydraulic mechanisms and pressure display units.

Storage

1. Dry Environment:

- Store the pellet press in a dry, dust-free environment. Moisture can cause rust and degrade the performance of the press.

- Use desiccants or silica gel packs to maintain humidity levels below 50%.

2. Protective Covers:

- Cover the press with a protective cloth or plastic cover when not in use. This prevents dust accumulation and accidental damage.

Regular Check-Ups

1. Monthly Inspections:

- Hydraulic System: Check the hydraulic fluid levels and replace if necessary. Ensure that there are no leaks and that the pressure relief mechanism is functioning correctly.

- Mechanical Parts: Inspect all mechanical parts, including bolts, clamps, and eccentric shafts, for wear and tear. Tighten any loose components and replace worn-out parts immediately.

2. Quarterly Maintenance:

- Lubrication: Lubricate all moving parts with high-quality grease. This includes the rollers, pistons, and hinges. Proper lubrication reduces friction and extends the lifespan of the press.

- Calibration: Calibrate the pressure force display in 10 kN steps to ensure accurate readings. Miscalibrated displays can lead to inconsistent pellet quality.

Additional Tips

1. Pellet Dimensions:

- Maintain a proper ratio between the height and diameter of the pellets. Generally, the height should not exceed the diameter to prevent cracking and other adverse effects. If pressing longer pellets, use lower forces and consider lubricating the die.

2. Sample Preparation:

- Ensure that the ground sample mix is evenly spread in the die cavity. Overfilling can lead to thicker pellets and potential damage to the press.

By following these maintenance and care practices, you can significantly enhance the longevity and performance of your manual pellet press. Regular cleaning, proper storage, and periodic check-ups are essential to ensure consistent and high-quality pellet production.

Optimizing Pellet Quality

Enhancing the quality of pellets produced using a manual pellet press involves several strategic adjustments and considerations. This section delves into key aspects such as force application, die selection, and material handling techniques to ensure optimal pellet quality.

Adjusting Force Application

The force applied during the pelletization process is a critical factor that directly influences pellet quality. It is essential to use a press equipped with a force gauge to accurately measure the force being applied. This ensures safe and effective pressing, leading to better pellet integrity. Cheap presses may lack a force gauge or provide only a pressure gauge, which measures the hydraulic pressure rather than the force applied to the die. It is crucial to understand the conversion from pressure to force using the effective surface area of the internal ram. Without this information, the accuracy of the pellet press is compromised.

Selecting Appropriate Die Sizes

Choosing the right die size is another pivotal aspect of pellet quality optimization. The general convention in pellet pressing is that the height (length) of a pellet should not significantly exceed its diameter. This is due to the increased stresses near the moving surface of the top plunger, which can lead to cracking or other adverse effects. For longer pellets, it is advisable to use lower forces, consider lubricating the die, and possibly use a small o-ring between the base plate and sleeve to evenly distribute the stresses throughout the compact.

Handling Materials

Proper handling of materials is essential to ensure consistent and high-quality pellets. When preparing samples for pelletization, it is important to maintain a constant sample amount and pressure to minimize errors in X-ray intensity measurements. Reproducibility can be improved by pelletizing the sample at a pressure where X-ray intensity saturates. After pelletization, the compressed ring and sample may slowly expand over time, causing a height difference between the sample surface and the ring, which can alter X-ray intensity or even lead to pellet breakage.

Step-by-Step Pellet Press Operation

- Fix the Pellet Press Together: Insert the die into the cavity.

- Transfer the Ground Sample Mix: Use a metal spatula to evenly spread the sample mix into the cavity. The amount of powder should be adjusted based on the desired pellet thickness.

- Insert the Bolt Press: Rotate it into the cavity to distribute the particles evenly.

- Secure the Die Set: Transfer the die set to the hydraulic pellet press and rotate the wheel to secure it tightly.

- Apply Pressure: Close the valve of the hydraulic press and pull the level until the handle becomes tight.

- Release the Die: To remove the die, first loosen the pressure, then move up the upper wheel of the press, and finally take out the die.

By carefully following these steps and considering the aforementioned factors, you can significantly enhance the quality of pellets produced using a manual pellet press. This comprehensive approach ensures that each pellet is consistent, free from defects, and suitable for various analytical applications.

Advanced Applications and Customization

Manual pellet presses are versatile tools in laboratory settings, particularly for preparing high-quality pellets used in spectral analyses such as X-ray fluorescence and infrared spectroscopy. These presses can be customized to meet specific research needs, enhancing their utility across various scientific applications.

Customizing Die Shapes and Sizes

One of the key aspects of customizing manual pellet presses is the selection and modification of die shapes and sizes. Dies are available in various diameters, such as 40 mm, 32 mm, and 15 mm, allowing for the preparation of pellets tailored to specific analytical requirements. The choice of die size can significantly influence the quality and consistency of the pellets, which is crucial for accurate and reproducible analytical results.

For instance, larger dies (e.g., 40 mm) are typically used for samples that require a higher volume of material or when a larger surface area is needed for analysis. Conversely, smaller dies (e.g., 15 mm) are suitable for samples with limited quantities or when a more concentrated analysis is required.

Advanced Pressing Techniques

Manual pellet presses can exert variable pressure forces up to 250 kN, with clear displays in 10 kN steps, ensuring precise control over the pressing process. This capability is essential for experiments that require specific pressure conditions to achieve optimal pellet density and homogeneity.

In some advanced applications, such as pressing long or tall pellets, longer die sleeves or plungers (75 mm or 90 mm height) are available as options. These specialized components allow for the preparation of elongated pellets, which can be necessary for certain analytical techniques or sample types.

Material Considerations

The materials used in die construction also play a critical role in the customization of manual pellet presses. For applications requiring higher stress levels, low-profile dies made from high-yield strength stainless steel can be utilized. These materials ensure durability and reliability under high-pressure conditions, minimizing the risk of equipment failure.

Reproducibility and Consistency

Ensuring reproducibility and consistency in sample preparation is paramount in analytical research. Manual pellet presses facilitate this by allowing researchers to maintain constant sample amounts and pressure for each pellet. This practice helps minimize errors due to variations in X-ray intensity, a common concern in X-ray fluorescence analysis.

Moreover, the use of forming agents (binders) can enhance the ease of pelletization, particularly for samples with challenging characteristics or grain sizes. Mixing the powder sample with a suitable binder can significantly improve pellet quality and consistency.

Die Types and Sample Characteristics

The selection of die type (flat disc or cylinder) depends on the characteristics of the powder sample. Flat disc dies are generally used for samples that require a uniform, flat surface, while cylinder dies are suitable for samples that need a more confined or elongated shape. The availability of dies in various inner diameters (10–43 mm) and materials (aluminum or PVC) further expands the customization options, catering to a wide range of sample types and analytical needs.

In conclusion, manual pellet presses offer extensive customization options through the selection and modification of die shapes, sizes, and materials. These adjustments enable researchers to tailor the pressing process to specific sample characteristics and analytical requirements, ensuring high-quality, reproducible pellets for accurate and reliable results in spectral analyses.

Related Products

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Ring Press Mold for Lab Applications