Automatic Heated Lab Press

Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

Item Number : PCV

Price varies based on specs and customizations

- Pressure range

- 0~25T

- Heating temperature

- 0-500℃

- Box size

- 400*400*400mm

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Applications

The heated hydraulic lab press for vacuum box is a specialized piece of equipment that is designed for use in laboratory settings. Its primary purpose is to press pills and powders according to specific needs.

One of the standout features of this lab press is the vacuum box that comes with it. The vacuum box allows for the pressing of samples in a vacuum environment, which can provide a number of benefits. For one, a vacuum environment helps to remove any air pockets or voids within the sample, which can lead to a more consistent and uniform end product. Additionally, a vacuum environment can help to reduce oxidation and degradation of the sample.

Feature

- Small footprint, light weight, easy to carry and move

- The vacuum box allows for the pressing of samples in a vacuum environment

- High precision digital pressure gauge.

- Pressure can be programmed, hydraulic will restart working when pressure drops to set value.

Detail & Parts

Advantages

- Chrome-plated cylinder, smooth surface, no rust, good sealing rubber ring, no oil leakage

- One-piece main board structure, oil pool, main board, oil cylinder in a body, no seal connection

- Mold using Japanese high-speed steel, good material, high hardness, no deformation, long service life

- Digital display pressure gauge, more accurate pressure control, pressure display accuracy of 0.01MPa

- Oil pool outside the host, easy to replace the oil, and the oil circuit increased the hydraulic oil filtration device

- Special plunger, using special custom sealing structure, excellent sealing effect

Technical specifications

| Instrument model | PCV-10T1818 | PCV-10T2020 |

|---|---|---|

| Pressure Range | 0-10.0 tons | 0-10.0 tons |

| Pressurization process | Manual pressurization | Manual pressurization |

| Heating temperature | Maximum 500°C | Maximum 500°C |

| Heating plate | 180×180mm | 200×200mm |

| Vacuum box material | SUS 304 (stainless steel) | SUS 304 (stainless steel) |

| Studio Size | 400×400×400mm | 400×100×400mm |

| Door size | 300×350mm | 300×350mm |

| Vacuum degree | -0.1MPa | -0.1MPa |

| Dimensions | 450×550×850(L×W×H) | 450×550×850(L×W×H) |

| Power supply | 220V50Hz (can support 110V) | 220V50Hz (can support 110V) |

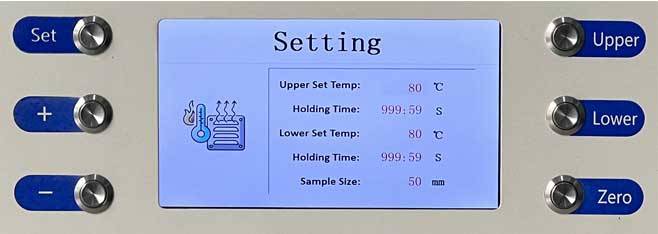

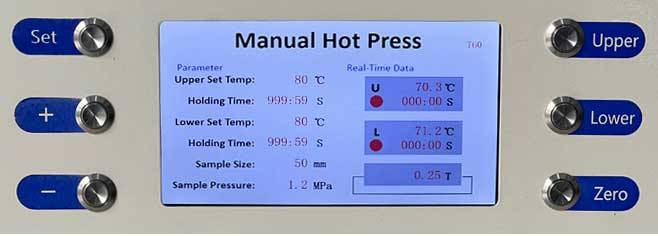

Setting interface

- Set: In the operation interface, press the settings button to enter the settings interface, then press the settings button to move the settings content. After moving to the mold diameter, press the settings button again to retum to the operation interface. Note: When the time is set to "0", it means that the time is set to infinity.

- +: In the operation interface, press the "+" key to increase the setting number.

- -: In the operation interface, press the "-" key to reduce the number of settings.

- Upper: Press the "Upper Plate" button on the operation interface, and the upper plate will start heating to the set temperature. After the automatic timing and constant temperature timer are completed,the heating will stop. Or press the "Upper Plate" button again to stop heating the upper plate. During the heating process, all setting buttons are invalid.

- Lower: Press the "Lower Plate" button on the operation interface, and the lower plate will start heating to the set temperature. After the automatic timing and constant temperature timer are completed, heating will stop.

- Zero: If the sample is not in contact, but the device has already displayed pressure, it may be due to the weight of the heating plate. We can press the "reset" button to reset the pressure to zero.

Operation steps

Step 1: Place the sample into the heating plate

Step 2: Pre press the sample and close the door to startvacuuming.Step 3: Adjust the Heating Temperature.

Step 3: Set the required heating temperature and insulation time.

Step 4: After setting up, return to the main operation interface.

Step 5: On the operation interface, press the up and down buttons to start heating the heating plate.

Step 6: Pump Down the Vacuum Box.

Step 7: After the pressurization is completed, release the vent valve and open the compartment door.

Step 8: Take out the sample.

Full range of lab press types

Click to view our full range of lab press products.

Any question? Our experts have helped many laboratories choose their lab press, contact us now!

Full range of types of laboratory press molds

We have a full range of molds for you to choose from, and the molds fit the body perfectly.

If you need molds with special shapes, we can also customize them for you.

Warnings

Operator safety is the top important issue! Please operate the equipment with cautions. Working with inflammable& explosive or toxic gases is very dangerous, operators must take all necessary precautions before starting the equipment. Working with positive pressure inside the reactors or chambers is dangerous, operator must fellow the safety procedures strictly. Extra caution must also be taken when operating with air-reactive materials, especially under vacuum. A leak can draw air into the apparatus and cause a violent reaction to occur.

Designed for You

KinTek provide deep custom made service and equipment to worldwide customers, our specialized teamwork and rich experienced engineers are capable to undertake the custom tailoring hardware and software equipment requirements, and help our customer to build up the exclusive and personalized equipment and solution!

Would you please drop your ideas to us, our engineers are ready for you now!

Trusted by Industry Leaders

FAQ

What Are The Advantages Of Using A Hydraulically Heated Laboratory Press?

What Does A Hydraulic Lab Heat Press Do?

What Types Of Samples Or Materials Can Be Processed In A Hydraulically Heated Laboratory Press?

How Does A Hydraulically Heated Laboratory Press Work?

How Can The Performance Of A Hydraulically Heated Laboratory Press Be Optimized?

4.8 / 5

I'm impressed by the smooth pressing and consistent results I get with this lab press. It's a valuable tool for our research.

4.7 / 5

The vacuum box feature is a game-changer. It allows us to achieve a more uniform and consistent sample, which is crucial for our analysis.

4.9 / 5

This lab press is a great addition to our lab. It's easy to use and produces high-quality pellets. We're very satisfied with our purchase.

4.6 / 5

The digital display pressure gauge is a nice touch. It allows us to precisely control the pressure applied to the sample.

4.8 / 5

The compact design saves valuable bench space in our lab, and the lightweight construction makes it easy to move around as needed.

4.7 / 5

The customer service from KINTEK SOLUTION was exceptional. They were responsive to our inquiries and provided helpful guidance.

4.9 / 5

The lab press arrived promptly and well-packaged. We were able to set it up and start using it right away.

4.6 / 5

The lab press is made of high-quality materials and feels sturdy and durable. We're confident it will last for years to come.

4.8 / 5

The lab press is incredibly user-friendly. The intuitive controls and clear instructions made it easy for our team to learn how to use it quickly.

4.7 / 5

KINTEK SOLUTION offers excellent technical support. They were able to answer all of our questions and provide valuable insights.

4.9 / 5

The lab press has exceeded our expectations in terms of performance and reliability. It's a valuable asset to our laboratory.

4.6 / 5

We're thrilled with our purchase of the lab press. It's a cost-effective solution that has improved the efficiency of our sample preparation process.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

The lab press for vacuum box is a specialized piece of equipment designed for laboratory use. Its main purpose is to press pills and powders according to specific requirements.

Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

The Automatic High Temperature Heat Press is a sophisticated hydraulic hot press designed for efficient temperature control and product quality processing.

Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

The Manual Heat Press is a versatile piece of equipment suitable for a variety of applications, operated by a manual hydraulic system that applies controlled pressure and heat to the material placed on the piston.

Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

Efficiently process heat-pressing samples with our Integrated Manual Heated Lab Press. With a heating range up to 500°C, it's perfect for various industries.

Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

Efficiently prepare your samples with our Automatic Heated Lab Press. With a pressure range up to 50T and precise control, it's perfect for various industries.

Electric Heated Hydraulic Vacuum Heat Press for Lab

The Electric Vacuum Heat Press is a specialized heat press equipment that operates in a vacuum environment, utilizing advanced infrared heating and precise temperature control for high quality, rugged and reliable performance.

30T 40T Split Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

Discover our split automatic heated lab press 30T/40T for precise sample preparation in material research, pharmacy, ceramics, and electronics industries. With a small footprint and heating up to 300°C, it's perfect for processing under vacuum environment.

Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

Efficiently prepare your samples with our Split Manual Heated Lab Press. With a pressure range up to 40T and heating plates up to 300°C, it's perfect for various industries.

Vacuum Hot Press Furnace Machine for Lamination and Heating

Experience clean and precise lamination with Vacuum Lamination Press. Perfect for wafer bonding, thin-film transformations, and LCP lamination. Order now!

Special Heat Press Mold for Lab Use

Square, round and flat plate forming dies for hot presses.

Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

Controlled environment lab press machine for glove box. Specialized equipment for material pressing and shaping with high precision digital pressure gauge.

Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

Reduce forming pressure & shorten sintering time with Vacuum Tube Hot Press Furnace for high-density, fine-grain materials. Ideal for refractory metals.

kbr pellet press 2t

Introducing the KINTEK KBR Press - a handheld laboratory hydraulic press designed for entry-level users.

Laboratory Manual Hydraulic Pellet Press for Lab Use

Efficient sample preparation with small footprint Manual Lab Hydraulic Press. Ideal for material researching labs, pharmacy, catalytic reaction, and ceramics.

Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

Experience efficient sample preparation with our Automatic Lab Press Machine. Ideal for material research, pharmacy, ceramics, and more. Features a compact size and hydraulic press functionality with heating plates. Available in various sizes.

Laboratory Hydraulic Press Lab Pellet Press for Button Battery

Efficiently prepare samples with our 2T Button Battery Press. Ideal for material research labs and small-scale production. Small footprint, lightweight, and vacuum-compatible.

Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

Fast and easy xrf sample pellet preparation with KinTek Automatic Lab Pellet Press. Versatile and accurate results for X-ray fluorescence analysis.

Laboratory Hydraulic Press Split Electric Lab Pellet Press

Efficiently prepare samples with a split electric lab press - available in various sizes and ideal for material research, pharmacy, and ceramics. Enjoy greater versatility and higher pressure with this portable and programmable option.

Ball Press Mold for Lab

Explore versatile Hydraulic Hot Press molds for precise compression molding. Ideal for creating various shapes and sizes with uniform stability.

Related Articles

The Physics of Flawless Materials: Deconstructing the Hydraulic Hot Press

Discover how the synergy of Pascal's Law and thermal energy in a hydraulic hot press enables precise, repeatable material bonding and forming.

Manual Pellet Press: A Comprehensive Guide to Efficient Lab Pelletizing

Explore the intricacies of manual pellet presses, including operation, safety, and maintenance tips. Learn how to choose the right press, understand force gauges, and optimize pellet quality for your lab experiments.

More Than a Squeeze: The Physics and Psychology of the Hydraulic Hot Press

An insight into the hydraulic hot press, where Pascal's Law meets thermodynamics to reshape materials. A story of force, heat, and control.

Comprehensive Guide to Vacuum Hot Press Furnace Application

The Vacuum Hot Press Furnace is a versatile tool especially suited for sintering experiments involving non-metallic materials, carbon composites, ceramic materials and metal powder materials.

Operating of Automatic Lab xrf Pellet Press

How to use the Automatic Lab xrf Pellet Press, including steel ring, plastic ring, boric acid mold

Tips With ADJUST THE PRESSURE OF THE LAB PRESS

When designing a pressure test, the required pressure is generally determined based on the material being tested. For example, softer materials may require less pressure than harder materials. The amount of pressure required will also depend on the specific test being performed.

Pressure and Heat: Forging Certainty into Matter

A hot press doesn't just shape materials; it eliminates hidden flaws and forges atomic-level trust. Learn the physics of material integrity.

Automatic flat plate heat press operating steps

The Benchtop KBr Pellet Press: An Efficient Tool for Laboratory Use

The benchtop KBr pellet press is a versatile and efficient tool that produces uniform pellets, ensuring consistent and reliable results. In addition, its adjustable mold can be used flexibly to accommodate a variety of sample sizes and shapes.

Beyond Brute Force: The Controlled Physics of Perfect Material Bonding

A hot press isn't just a heater and a press. It's a system where controlled heat and force unite for flawless, repeatable material bonding.

Fully automatic tablet press operating steps and replacement accessories

Relevant introduction to the operating steps and replacement accessories of the fully automatic tablet press

The Key Features of Lab Presses

Laboratory presses are an essential tool for many scientific applications, including materials science, chemistry, and physics. They are used to create uniform and well-compacted samples for testing, and they can be used for a wide range of materials, including powders, pellets, and films.