Introduction

Table of Contents

- Introduction

- Applications and Working Process of Lab Scale Mini Tablet Press

- Description of the KinTek Lab Scale Single Sided Rotary Tablet Press

- Compact table top machine for small batch tablet production

- Design and technology compliance with cGMP

- Ease of operation, cleaning, and maintenance

- Availability in three different models with specific tooling stations

- Optional features including force feeding system, pre pressing system, and PLC controls with MMI touch screen interface

- Salient Features of Lab Scale Single Sided Rotary Tablet Press

- Optional Features of Lab Scale Mini Tablet Press

- Safety Features of Lab Scale Mini Tablet Press

- Conclusion

The lab scale mini tablet press is a versatile and essential tool in pharmaceutical and relevant industries. It plays a crucial role in the production of simple and precise tablets from powder, making it indispensable in research and development. This compact table top machine is designed to comply with cGMP standards, ensuring quality and safety. Its ease of operation, cleaning, and maintenance make it a convenient choice for small batch tablet production. With a maximum capacity of 18,000 tablets per hour, this lab scale mini tablet press offers efficiency and reliability in a compact and user-friendly package.

Applications and Working Process of Lab Scale Mini Tablet Press

Use of Lab Tablet Press Machine in pharmaceutical and relevant industries

Lab tablet press machines are widely used in the pharmaceutical and relevant industries for research and development purposes. These machines are specifically designed to produce simple and precise tablets from powder. They play a crucial role in the formulation development process, allowing researchers to test and experiment with different formulations in small batches. Lab tablet presses are essential tools for pharmaceutical companies to optimize their tablet production processes and ensure the quality and consistency of their products.

Role in the production of simple and precise tablets from powder

Lab tablet presses are instrumental in the production of simple and precise tablets from powder. These machines provide researchers with the ability to accurately measure and compress powdered materials into tablet form. The tablets produced by lab tablet presses have uniform size, weight, and composition, ensuring consistent dosage and effectiveness of pharmaceutical products. The compact design and advanced technology of lab tablet presses allow for high precision and efficient tablet production.

Importance in research and development

Lab tablet presses play a crucial role in research and development activities in the pharmaceutical industry. These machines enable scientists and researchers to test and evaluate different formulations and dosage forms in small quantities. Lab tablet presses allow for rapid prototyping and optimization of tablet formulations, helping pharmaceutical companies streamline their product development processes. The precision and reliability of lab tablet presses are essential for ensuring accurate and reproducible results in research and development.

Lab tablet presses are also used in other industries such as laminating, rubber and plastic molding, and chemical manufacturing. These machines are versatile and can be used for a wide range of applications, including testing, short runs, limited production, cell manufacturing, and lean manufacturing.

In conclusion, lab scale mini tablet presses are valuable tools in the pharmaceutical and relevant industries. They enable the production of simple and precise tablets from powder, facilitate research and development activities, and ensure the quality and consistency of pharmaceutical products. Lab tablet presses are essential for optimizing tablet production processes and driving innovation in the pharmaceutical industry.

Description of the KinTek Lab Scale Single Sided Rotary Tablet Press

The KinTek Lab Scale Single Sided Rotary Tablet Press is a compact table top machine designed for small batch tablet production in the field of formulation development and research and development (R&D). It is widely used in industries such as pharmacy, chemical, food, and metallurgy.

Compact table top machine for small batch tablet production

The KinTek Lab Scale Single Sided Rotary Tablet Press is specifically designed for small batch tablet production. Its compact size makes it ideal for use in laboratory settings or for small-scale production. Despite its small size, this machine is capable of producing tablets with high precision and efficiency.

Design and technology compliance with cGMP

This tablet press machine is designed to exceed the highest cGMP (Current Good Manufacturing Practices) requirements. It is manufactured with advanced technology and adheres to strict design standards to ensure compliance with cGMP regulations. This ensures that the tablets produced using this machine meet the highest quality standards.

Ease of operation, cleaning, and maintenance

The KinTek Lab Scale Single Sided Rotary Tablet Press is designed with ease of operation, cleaning, and maintenance in mind. It features a user-friendly interface and intuitive controls, making it easy for operators to operate the machine. Additionally, the machine is designed for easy cleaning and maintenance, allowing for efficient and hassle-free operation.

Availability in three different models with specific tooling stations

The KinTek Lab Scale Single Sided Rotary Tablet Press is available in three different models, each with specific tooling stations. The models include the Tooling 8 Station with "D" Type, 10 Station with "B" Tooling, and 12 Station with combined "D", "B", and "BB" Type. These different models provide flexibility and options for different tablet production needs.

Optional features including force feeding system, pre pressing system, and PLC controls with MMI touch screen interface

The KinTek Lab Scale Single Sided Rotary Tablet Press offers optional features that can enhance its functionality and performance. These optional features include a force feeding system, pre pressing system, and PLC controls with MMI touch screen interface. These features provide additional control and automation, improving efficiency and accuracy in tablet production.

In conclusion, the KinTek Lab Scale Single Sided Rotary Tablet Press is a versatile and efficient machine designed for small batch tablet production in R&D and formulation development. Its compact size, compliance with cGMP, ease of operation and maintenance, and optional features make it a valuable tool for businesses in the pharmaceutical, chemical, food, and metallurgy industries.

Salient Features of Lab Scale Single Sided Rotary Tablet Press

-

cGMP compliance in design: The Lab Scale Single Sided Rotary Tablet Press is designed to comply with Current Good Manufacturing Practices (cGMP), ensuring the highest quality standards in tablet production.

-

Use of AISI 316 for contact parts and AISI 304 for non-contact parts: The machine is constructed using high-quality materials, with AISI 316 stainless steel used for contact parts and AISI 304 stainless steel used for non-contact parts. This ensures durability, corrosion resistance, and hygienic operation.

-

Convenience in operation, changeover, cleanliness, operator protection, and maintenance: The Lab Scale Single Sided Rotary Tablet Press is designed for ease of use. It offers convenient operation, easy changeover between different tablet formulations, and simple cleaning procedures. Additionally, it provides operator protection features and requires minimal maintenance.

-

Maximum capacity of 18,000 tablets per hour: Despite its compact size, the Lab Scale Single Sided Rotary Tablet Press has a high production capacity of up to 18,000 tablets per hour. This makes it suitable for small batch tablet production.

-

Incorporation of standard medium batch features in a small, compact machine: The Lab Scale Single Sided Rotary Tablet Press incorporates features typically found in larger machines designed for medium batch production. This allows for efficient tablet production in a small, space-saving design.

-

AC frequency variable speed drive for turret: The machine is equipped with an AC frequency variable speed drive for the turret, allowing for precise control over the tablet production process.

-

Open type fixed gravity feed frame: The Lab Scale Single Sided Rotary Tablet Press features an open-type fixed gravity feed frame, making it easy to feed the powder into the machine during operation.

-

Location of tablet thickness setting, weight adjustment, and speed controls outside of the machine: The tablet thickness setting, weight adjustment, and speed controls are conveniently located outside of the machine, ensuring easy access and quick adjustments.

-

Lower guard of S.S.304Q & Upper Guard of Acrylic Glass with limit switch: The Lab Scale Single Sided Rotary Tablet Press is designed with safety in mind. It features a lower guard made of S.S.304Q stainless steel and an upper guard made of acrylic glass, both equipped with limit switches to ensure operator safety.

The Lab Scale Single Sided Rotary Tablet Press offers a compact and efficient solution for small batch tablet production. With its cGMP compliance, use of high-quality materials, convenient operation, and safety features, it provides a reliable and user-friendly option for formulation development and pilot production.

Optional Features of Lab Scale Mini Tablet Press

The KinTek Lab Scale Single Sided Rotary Tablet Press is a compact tabletop machine used for formulation development in R&D for small batch tablet production. It exceeds the highest cGMP requirements with advanced technology, ergonomic design, and efficiency. The optional features of the Lab Scale Mini Tablet Press include:

Pre Pressing system

The pre-pressing system in the Lab Scale Mini Tablet Press ensures better tablet hardness and uniformity. It allows for the pre-compression of the powder before the main compression stage. This feature is beneficial for achieving tablets with consistent weight and thickness.

Rotary force powder feeder

The rotary force powder feeder is another optional feature of the Lab Scale Mini Tablet Press. This feature enables the controlled feeding of the powder into the compression zone. It ensures accurate dosing and reduces the risk of powder segregation, resulting in high-quality tablets.

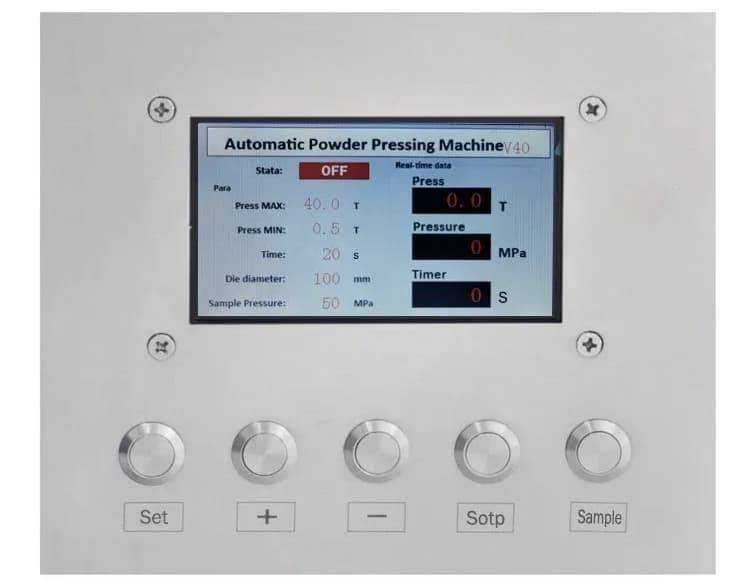

PLC controls with HMI Touch Screen Interface

The Lab Scale Mini Tablet Press is equipped with PLC controls and an HMI touch screen interface. This feature provides user-friendly operation and control of the tablet press. The touch screen interface allows for easy adjustment of tablet thickness, weight, and speed controls. It also provides real-time monitoring of the machine's performance.

With these optional features, the Lab Scale Mini Tablet Press offers enhanced capabilities for tablet production in research and development settings. It ensures precise tablet compression, improved tablet quality, and ease of operation.

Safety Features of Lab Scale Mini Tablet Press

Safety Acrylic guard with limit switch

The Lab Scale Mini Tablet Press is equipped with a safety acrylic guard that has a limit switch. This guard acts as a protective barrier, preventing access to the compression zone during operation. The limit switch ensures that the machine stops automatically if the guard is lifted or tampered with, ensuring the safety of the operator.

Location of all controls outside of the compression zone for safety

To further enhance safety, all controls of the Lab Scale Mini Tablet Press are located outside of the compression zone. This means that the operator does not need to enter the compression zone to adjust or operate the machine. By keeping the controls outside, the risk of accidents or injury is minimized, making the machine safer to use.

Overload relay controls

The Lab Scale Mini Tablet Press is equipped with overload relay controls. These controls monitor the load on the machine and can detect if it is operating beyond its capacity. If an overload is detected, the relay automatically stops the machine to prevent damage or accidents. This feature ensures the longevity of the machine and protects the operator from any potential hazards.

The safety features of the Lab Scale Mini Tablet Press are designed to prioritize the well-being of the operator and prevent accidents or injuries. With the safety acrylic guard, limit switch, controls located outside the compression zone, and overload relay controls, this machine provides a safe working environment for pharmaceutical and relevant industries.

Conclusion

In conclusion, the lab scale mini tablet press is a crucial tool in the pharmaceutical and relevant industries. It plays a significant role in the production of simple and precise tablets from powder, making it essential for research and development. The KinTek Lab Scale Single Sided Rotary Tablet Press offers a compact design that complies with cGMP standards. With its ease of operation, cleaning, and maintenance, it provides convenience for users. The optional features, such as the force feeding system and PLC controls with MMI touch screen interface, enhance its functionality. Overall, the lab scale mini tablet press is a reliable and efficient machine for small batch tablet production.

If you are interested in this product you can browse our company website:https://kindle-tech.com/product-categories/heated-lab-press, we understand that every customer's needs are unique. Therefore, we offer a flexible customisation service to meet your specific requirements. Whether it is the specification, functionality or design of the equipment, we are able to personalise it to suit your needs. Our dedicated team will work closely with you to ensure that the customised solution will perfectly meet your experimental needs.

Related Products

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

Related Articles

- Automatic Hydraulic Press: The Ultimate Guide for Efficient Sample Preparation and Industrial Processes

- Fully automatic tablet press operating steps and replacement accessories

- Applications and Importance of Hydraulic Press in Laboratories

- How to choose a laboratory hot press

- A Comprehensive Guide on Pressing XRF Pellets Using a KinTek Automatic Hydraulic Press