Manual Heated Lab Press

Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

Item Number : PCY

Price varies based on specs and customizations

- Working pressure

- 0-10 T

- Heating plate

- 200mm*200mm

- Heating temperature

- <500 ℃

- Cooling method

- Chiller circulator

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Applications

Hydraulic lab press is widely used in material researching labs,pharmacy,catalytic reaction,ceramics, electronic industries, it is one high efficient equipment for the sample preparing, due to its small footprint, it easy to carry and move, can work inside the vacuum glove box for processing under vacuum environment. Hydraulic press can also process hot press function with heating plates, which can serve the particular material processing.

Integrated lab heat press has a better structure, which is convenient for processing samples that need heat pressing. can be heated up to 500°C.

Feature

- Fast heating, heating plate can be single side or double side

- Water circulating fast cooling to protect the press

- Max. Heating temperature is up to 500 ℃

- Small footprint, light weight, easy to carry and move, nice fitting vacuum glove box

Detail & Parts

Advantages

- The upper plate adopts electroplated countersunk head hexagonal screws, beautiful and space-saving

- Chrome-plated cylinder, smooth surface, no rust, good sealing rubber ring, no oil leakage

- One-piece main board structure, oil pool, main board, oil cylinder in a body, no seal connection

- Extended pulling spring, good rebound effect, not easy to deformation, can achieve the cylinder 30mm return without deformation

- All aluminum alloy hand wheel, beautiful, practical, not easy to break

- Small size, light weight, no oil leakage, can be used in the glove box

- Mold using Japanese high-speed steel, good material, high hardness, no deformation, long service life

- Digital display pressure gauge, more accurate pressure control, pressure display accuracy of 0.01MPa

- Oil pool outside the host, easy to replace the oil, and the oil circuit increased the hydraulic oil filtration device

- Special plunger, using special custom sealing structure, excellent sealing effect

- Pressurizing device, placed in the lowermost corner of the mainframe, the angle is reasonable, pressurizing force does not tilt back

Technical specifications

| Instrument model | PCY-5T1212 | PCY-10T1818 | PCY-10T2020 | PCY-15T3030 |

|---|---|---|---|---|

| Pressure Range | 0-5.0 tons | 0-10.0 tons | 0-10.0 tons | 0-15.0 tons |

| Piston diameter | 50mm (d) in chrome plated oil cylinder | 65mm (d) in chrome plated oil cylinder | 65mm (d) in chrome plated oil cylinder | 95mm (d) in chrome plated oil cylinder |

| Main overall structure | Equipment without sealed connections to reduce oil leakage points | Equipment without sealed connections to reduce oil leakage points | Equipment without sealed connections to reduce oil leakage points | Equipmentwithout sealed connections to reduce oil leakage points |

| Mold heating temperature | Room temperature -300.0C/500.0C | Room temperature-300.0C/500.0C | Room temperature-300.0C/500.0C | Room temperature-300.0C/500.0C |

| Insulation method | Imported insulation board | Imported insulation board | Imported insulation board | Imported insulation board |

| Cooling method | Quick cooling with water cooling [optional water cooling machine] | Quick cooling with water cooling [optional water cooling machine] | Quick cooling with water cooling [optional water cooling machine] | Quick cooling with water cooling [optional water cooling machine] |

| Hot platen size | Double plate heating 120×120mm(M×N) | Double plate heating 180×180mm(M×N) | Double plate heating200×200mm(M×N) | Double plate heating300×300mm(M×N) |

| Workspace | 140×140×60mm | 180×180×60mm | 200×200×60 mm | 300×300×65mm |

| Dimensions | 250×230×390mm(L×W×H) | 290×290×420mm(L×W×H) | 320×290×420mm(L×W×H) | 450×420×450mm(L×W×H) |

| Power supply | 700W(220V/110V can be customized) | 1000 W(220V/110V can be customized) | 1200 W(220V/110V can be customized) | 3000 W(220V/110V can be customized) |

| Weight | 55 Kg | 90 Kg | 95Kg | 180Kg |

| Dimensional diagram of powder tablet press | See picture below | See picture below | See picture below | See picture below |

- Convenience: The electric heating tablet press has the advantages of small size, fast heating, rapid cooling, and easy use. It is widely used in the plastic and rubber industry.

- Efficiency: The use of water cooling cycle cooling can accelerate the cooling rate of the sample after molding, reduce the sample preparation time, and improve efficiency.

- Accuracy: PLC program temperature control is adopted to effectively prevent the temperature from overshooting when the heating mold heats up. The temperature display of 0.1°C is more accurate.

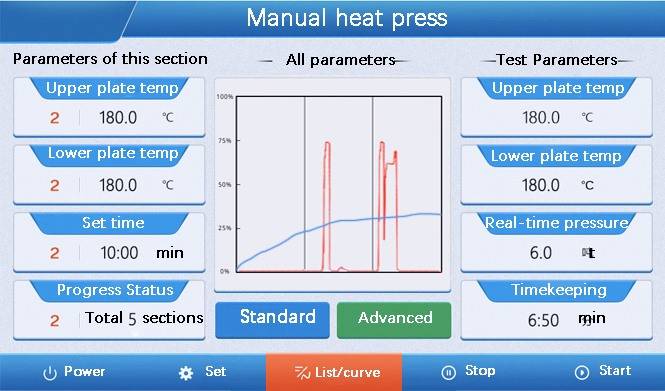

Operation interface

- Standard interface: You can set the upper and lower plate heating temperature and constant temperature time separately in this interface.

- Zero button: Calibrate the pressure and return the pressure to zero.

- Upper plate button: Heat the upper heating plate.

- Lower plate button: Heat the lower heating plate.

- Timer switch: You can turn the timer function on and off.

- Start button: You can heat up according to the multi-stage heating program.

- Stop button: During the heating process, you can stop the heating process.

- Setting button: Click the setting button to enter the setting menu.

- List/Graph: You can switch between list and graph display.

Operation steps

How to replace accessories and precautions

Please click the link

1. In standard mode, you can set temperature, time, and size individually.

2. Enter the value and save.

3. Start heating the upper and lower plates.

4. Put the mold into the tablet press.

5. When the temperature reaches the set temperature, we start pressurizing.

6. Take out the pressed sample.

Full range of lab press types

Click to view our full range of lab press products.

Any question? Our experts have helped many laboratories choose their lab press, contact us now!

Full range of types of laboratory press molds

We have a full range of molds for you to choose from, and the molds fit the body perfectly.

If you need molds with special shapes, we can also customize them for you.

Warnings

Operator safety is the top important issue! Please operate the equipment with cautions. Working with inflammable& explosive or toxic gases is very dangerous, operators must take all necessary precautions before starting the equipment. Working with positive pressure inside the reactors or chambers is dangerous, operator must fellow the safety procedures strictly. Extra caution must also be taken when operating with air-reactive materials, especially under vacuum. A leak can draw air into the apparatus and cause a violent reaction to occur.

Designed for You

KinTek provide deep custom made service and equipment to worldwide customers, our specialized teamwork and rich experienced engineers are capable to undertake the custom tailoring hardware and software equipment requirements, and help our customer to build up the exclusive and personalized equipment and solution!

Would you please drop your ideas to us, our engineers are ready for you now!

Trusted by Industry Leaders

FAQ

What Are The Advantages Of Using A Hydraulically Heated Laboratory Press?

What Does A Hydraulic Lab Heat Press Do?

What Types Of Samples Or Materials Can Be Processed In A Hydraulically Heated Laboratory Press?

How Does A Hydraulically Heated Laboratory Press Work?

How Can The Performance Of A Hydraulically Heated Laboratory Press Be Optimized?

4.8 / 5

The delivery of my integrated manual heated lab pellet press was lightning fast, arriving within days of placing the order. I appreciate the prompt service.

4.9 / 5

This lab pellet press is an incredible value for the price. It's well-made, easy to use, and produces high-quality pellets. I highly recommend it to anyone in need of a lab pellet press.

4.7 / 5

The quality of this lab pellet press is top-notch. It's made from durable materials and feels like it will last for years to come. I'm very satisfied with my purchase.

4.8 / 5

I've been using this lab pellet press for several months now and it's still going strong. It's very durable and has held up well to the demands of my lab work.

4.9 / 5

The technological advancement of this lab pellet press is impressive. It's equipped with the latest features and capabilities, making it a valuable asset to my lab. I'm very happy with my purchase.

4.8 / 5

I'm thoroughly impressed with the speed of delivery for this lab pellet press. It arrived within days of placing the order, allowing me to start using it right away. The prompt service is greatly appreciated.

4.7 / 5

The value for money of this lab pellet press is exceptional. It's an affordable option that doesn't compromise on quality or performance. I highly recommend it to anyone on a budget.

4.9 / 5

The quality of this lab pellet press is outstanding. It's made from high-quality materials and is built to last. I'm confident that it will provide years of reliable service.

4.8 / 5

The durability of this lab pellet press is remarkable. It's been through a lot of use in my lab and it's still going strong. I'm very impressed with its longevity.

4.9 / 5

The technological advancement of this lab pellet press is cutting-edge. It's equipped with the latest features and capabilities, making it a valuable asset to my research. I'm very happy with my purchase.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

The Automatic High Temperature Heat Press is a sophisticated hydraulic hot press designed for efficient temperature control and product quality processing.

Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

Efficiently prepare your samples with our Automatic Heated Lab Press. With a pressure range up to 50T and precise control, it's perfect for various industries.

30T 40T Split Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

Discover our split automatic heated lab press 30T/40T for precise sample preparation in material research, pharmacy, ceramics, and electronics industries. With a small footprint and heating up to 300°C, it's perfect for processing under vacuum environment.

Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

The Manual Heat Press is a versatile piece of equipment suitable for a variety of applications, operated by a manual hydraulic system that applies controlled pressure and heat to the material placed on the piston.

Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

Enhance your lab's precision with our lab press for vacuum box. Press pills and powders with ease and precision in a vacuum environment, reducing oxidation and improving consistency. Compact and easy to use with a digital pressure gauge.

Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

The lab press for vacuum box is a specialized piece of equipment designed for laboratory use. Its main purpose is to press pills and powders according to specific requirements.

Laboratory Manual Hydraulic Pellet Press for Lab Use

Efficient sample preparation with small footprint Manual Lab Hydraulic Press. Ideal for material researching labs, pharmacy, catalytic reaction, and ceramics.

Electric Heated Hydraulic Vacuum Heat Press for Lab

The Electric Vacuum Heat Press is a specialized heat press equipment that operates in a vacuum environment, utilizing advanced infrared heating and precise temperature control for high quality, rugged and reliable performance.

Laboratory Manual Hydraulic Pellet Press for Lab Use

Efficient Manure Lab Hydraulic Press with Safety Cover for sample preparation in material research, pharmacy, and electronic industries. Available in 15T to 60T.

Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

Controlled environment lab press machine for glove box. Specialized equipment for material pressing and shaping with high precision digital pressure gauge.

Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

Fast and easy xrf sample pellet preparation with KinTek Automatic Lab Pellet Press. Versatile and accurate results for X-ray fluorescence analysis.

Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

Efficiently prepare your samples with our Split Manual Heated Lab Press. With a pressure range up to 40T and heating plates up to 300°C, it's perfect for various industries.

kbr pellet press 2t

Introducing the KINTEK KBR Press - a handheld laboratory hydraulic press designed for entry-level users.

Anti-Cracking Press Mold for Lab Use

The anti-cracking press mold is a specialized equipment designed for molding various shapes and sizes of film using high pressure and electric heating.

Laboratory Hydraulic Press Lab Pellet Press for Button Battery

Efficiently prepare samples with our 2T Button Battery Press. Ideal for material research labs and small-scale production. Small footprint, lightweight, and vacuum-compatible.

Laboratory Hydraulic Press Split Electric Lab Pellet Press

Efficiently prepare samples with a split electric lab press - available in various sizes and ideal for material research, pharmacy, and ceramics. Enjoy greater versatility and higher pressure with this portable and programmable option.

Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

Efficiently prepare samples with the Electric Hydraulic Press. Compact and portable, it's perfect for labs and can work in a vacuum environment.

Ball Press Mold for Lab

Explore versatile Hydraulic Hot Press molds for precise compression molding. Ideal for creating various shapes and sizes with uniform stability.

Rubber Vulcanizer Vulcanizing Machine Plate Vulcanizing Press for Lab

The Plate vulcanizing press is a kind of equipment used in the production of rubber products, mainly used for the vulcanization of rubber products. Vulcanization is a key step in rubber processing.

Related Articles

Comprehensive Guide to Integrated Manual Heated Lab Pellet Presses

Explore the features and applications of integrated manual heated lab pellet presses. Learn about customization options, capacities, and benefits for spectroscopy and analysis.

Precision Under Pressure: The Physics and Psychology of the Hydraulic Hot Press

Discover how the synergy of heat and pressure in a hydraulic hot press transforms materials, guided by the elegant physics of Pascal's Law.

More Than a Squeeze: The Physics and Psychology of the Hydraulic Hot Press

An insight into the hydraulic hot press, where Pascal's Law meets thermodynamics to reshape materials. A story of force, heat, and control.

Hydraulic Heated Lab Pellet Press: Comprehensive Guide to Selection and Usage

Explore the features and applications of hydraulic heated lab pellet presses. Learn how to choose the right model for your research needs and maximize efficiency in material science labs.

The Physics of Flawless Materials: Deconstructing the Hydraulic Hot Press

Discover how the synergy of Pascal's Law and thermal energy in a hydraulic hot press enables precise, repeatable material bonding and forming.

Automatic flat plate heat press operating steps

Comprehensive Guide to Cylindrical Lab Electric Heating Press Mold: Technology and Applications

Explore the advanced features and applications of cylindrical lab electric heating press molds. Learn about their working principles, types of heating technologies, and key benefits for precise sample preparation.

Pressure and Heat: Forging Certainty into Matter

A hot press doesn't just shape materials; it eliminates hidden flaws and forges atomic-level trust. Learn the physics of material integrity.

Automatic Hydraulic Press: The Ultimate Guide for Efficient Sample Preparation and Industrial Processes

Discover the world of automatic hydraulic presses, from their versatile applications in industrial XRF and laboratory sample manipulation to their role in large-scale manufacturing, hot embossing, laminating, and polymer melting. Learn about their benefits, features, and how they revolutionize sample preparation and industrial processes.

How to choose a laboratory hot press

The laboratory hot pressing machine is suitable for laboratory users who are strict about sample pressing temperature, pressure control accuracy and need a wide size mold for pressing samples. The new lab hot press of KINDLE TECH has a double-plate structure and a pressing force of 0~40 tons.

Vacuum Hot Press Furnace: A Comprehensive Guide

Gain in-depth knowledge of Vacuum Hot Press Furnaces, their components, benefits, and applications in various industries. Explore how these furnaces revolutionize material processing and achieve exceptional results.

Comprehensive Guide to Hydraulic Hot Press: Function, Features and Applications

Hydraulic hot press is equipped with advanced electronic controls that allow for precise temperature selection and technical control. This enables the machine to automatically carry out processes such as stage temperature adjustment and film pressure control.