Customer-made Press

Electric Heated Hydraulic Vacuum Heat Press for Lab

Item Number : PPZ

Price varies based on specs and customizations

- Pressure Range

- 0-25T

- Heating temperature

- Up to 500℃

- Cooked tablet

- 180x180mm,200x200mm

- Vacuum box material

- SUS 304 (stainless steel)

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Introduction

The Electric Vacuum Heat Press is a specialized hot pressing device that operates within a vacuum environment, utilizing advanced infrared heating and precise temperature control for high-quality, robust, and reliable performance. This equipment, designed for longevity and low maintenance, offers both manual and automatic operation modes, with innovative semi-automatic models also available. It features a variety of designs, including clamshell, swing-away, and draw style presses, and utilizes air pressure for effective force application.

Applications

The Electric Vacuum Heat Press is a versatile tool used in various industries for precise heating and pressure application under controlled vacuum conditions. This technology is particularly beneficial in processes that require high purity, uniform heating, and the removal of trapped gases or liquids. The applications of this equipment span across multiple sectors, including advanced materials processing, semiconductor manufacturing, and aerospace engineering.

- Advanced Materials Processing: Used for sintering and densifying advanced ceramics and composites, ensuring uniform heating and pressure distribution to achieve high-quality, high-performance materials.

- Semiconductor Manufacturing: Essential in the fabrication of semiconductor devices where precise control of heat and vacuum conditions is crucial for the integrity of thin films and wafers.

- Aerospace Engineering: Employed in the production of aerospace components that require high strength and lightweight properties, often involving the consolidation of composite materials under vacuum.

- Research and Development: Widely used in laboratories for experimental purposes, particularly in materials science where the effects of vacuum and heat on various substances are studied.

- Medical Device Manufacturing: Used in the production of medical implants and devices where sterilization and the absence of contaminants are critical.

- Optoelectronics: Involved in the manufacturing of optical components and devices where precise temperature control and the absence of impurities are necessary.

Detail & Parts

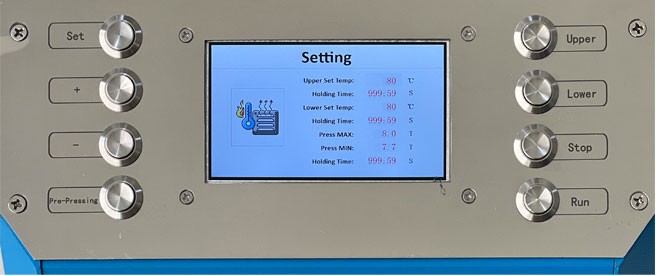

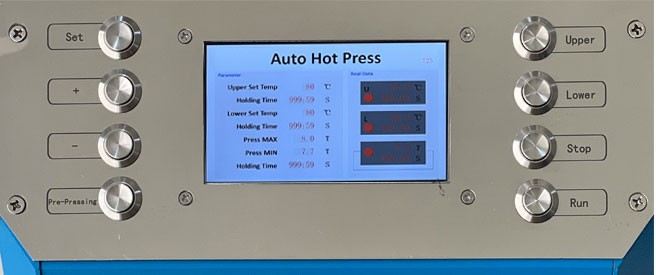

-Sample Preparation Process -Release Process

- Set:In the operation interface, press the settings button to enter the settings interface, then press the settings button to move the settings content. After moving to the mold diameter, press the settings button again to return to the operation interface. Note: When the time is set to "0", it means that the time is set to infinity

- +:In the operation interface, press the "+" key to increase the setting number

- -:In the operation interface, press the "_" key to reduce the number of settings

- Pre-Pressing:Press the pre pressing button to close the upper and lower heating plates together

- Upper:Press the "Upper Plate" button on the operation interface, and the upper plate will start heating to the set temperature. After the timing and constant temperature timer are completed, the heating will stop. Or press the "Upper Plate" button again to stop heating the upper plate. During the heating process, all setting buttons are invalid.

- Lower:Press "Lower Board" on the operation interface to stop heating after the timer ends. Or press the "Lower Plate" button again to stop heating the lower plate.

- Stop:When the device is in operation, pressing the "Stop" button will stop the motor from running and open the pressure relief valve to release the pressure

- Run:Press the "pressurization" button, and the equipment will start. When the pressure reaches the set pressure, stop pressurization and time to maintain pressure. When it is below the lower limit of pressurization, it will automatically replenish pressure. After the timing is completed, it will automatically release pressure

Features

The Electric Vacuum Heat Press is a cutting-edge solution for precise and efficient hot pressing, designed to operate within a vacuum environment. This machine is a testament to over five decades of expertise in cabin interior work, ensuring high quality and reliability. Its features are not only robust but also user-friendly, making it an ideal choice for both professional and hobbyist applications.

- Quick, Minimum-Fuss Installation: Simplifying the setup process, this feature ensures that users can start their projects without any hassle, saving time and effort.

- Designed for Longevity: Built to last, the machine is engineered for a very long life, reducing the need for frequent replacements and ensuring consistent performance over the years.

- High Quality and Robust Construction: The robust design guarantees reliability and durability, making it a dependable tool for demanding applications.

- Low Maintenance: With minimal maintenance requirements, the machine offers a cost-effective solution by reducing the time and resources needed for upkeep.

- Supplied Worldwide: Accessible globally, this feature ensures that users from different regions can benefit from the advanced capabilities of the Electric Vacuum Heat Press.

- Highly Responsive Infrared Heating: This technology provides rapid and even heating, enhancing the efficiency and quality of the pressing process.

- Class-Leading Temperature Control: Precise temperature regulation ensures optimal results, allowing for fine-tuning according to specific project requirements.

- Excellent Vacuum Press Power with Integral Vacuum Pump: The integral vacuum pump enhances the machine's functionality, providing powerful and effective vacuum press capabilities.

- Versatile Temperature Settings: With three heat settings (Low: 284℉, Medium: 320℉, High: 374℉), the Mini Easy Press machine caters to a wide range of heat transfer needs, ensuring versatility and adaptability.

- Ceramic Coated Dry Heat Plate: The ceramic coating on the sole plate ensures even heat distribution, leading to superior results in various projects.

- Compact and Portable Design: The Mini Easy Press machine is designed to be small and easy to carry, making it convenient for users who need to work in different locations or have limited workspace.

- Included Accessories: The package comes with a water spray bottle and a small canvas bag, enhancing the user experience by simplifying the ironing process and providing storage convenience.

This machine is particularly suited for craft enthusiasts, students, and housewives, enabling them to bring their creative ideas to life with precision and ease.

Principle

The Electric Vacuum Heat Press operates by applying electrical heat to materials within a vacuum environment, facilitating off-gassing and lowering the boiling point of trapped liquids. This process enhances product quality during drying and high-purity processing. The press utilizes pulse heating, where voltage and current are alternated to rapidly generate heat, optimizing the welding head's temperature.

Advantages

The Electric Vacuum Heat Press stands out as a superior choice for various applications, particularly in the realm of crafting and industrial processes. Here are some of its key advantages:

-

Highly Responsive Infrared Heating: This feature ensures rapid and even heating, which is crucial for maintaining the integrity of materials being processed. The infrared heating system is not only efficient but also conserves energy, making it an eco-friendly choice.

-

Class-Leading Temperature Control: With advanced temperature control mechanisms, the Electric Vacuum Heat Press offers precise temperature regulation. This is essential for achieving consistent results and preventing material degradation during the pressing process.

-

Excellent Vacuum Press Power: Equipped with an integral vacuum pump, this heat press provides powerful vacuum sealing capabilities. This ensures that the materials are held firmly in place, reducing the risk of air bubbles or uneven pressing.

-

Low Maintenance: Designed for longevity and reliability, this heat press requires minimal maintenance. This not only saves time but also reduces the overall cost of ownership, making it a cost-effective solution for both hobbyists and professionals.

-

Quick, Minimum-Fuss Installation: The ease of installation is another significant advantage. Users can quickly set up the machine and start their projects without any hassle, which is ideal for those who value efficiency and convenience.

-

Designed for Long Life: Built with durability in mind, the Electric Vacuum Heat Press is constructed to withstand heavy use over an extended period. This makes it a wise investment for those looking for a machine that will serve them well into the future.

-

Supplied Worldwide: Availability on a global scale ensures that users from different parts of the world can access this high-quality equipment. This international supply chain also supports a wide range of customer needs and applications.

-

Great Practicality: Despite its robust features, the machine is compact and versatile, making it suitable for a variety of heat transfer projects. Whether it's transferring designs onto T-shirts, bags, or other materials, the mini heat press offers great practicality and flexibility.

-

Honed and Refined: With over 50 years of experience in cabin interior work, the design and functionality of the Electric Vacuum Heat Press have been meticulously refined to meet the highest standards of quality and performance.

These advantages make the Electric Vacuum Heat Press an indispensable tool for anyone involved in crafting, manufacturing, or any process that requires precise and efficient heat pressing under controlled vacuum conditions.

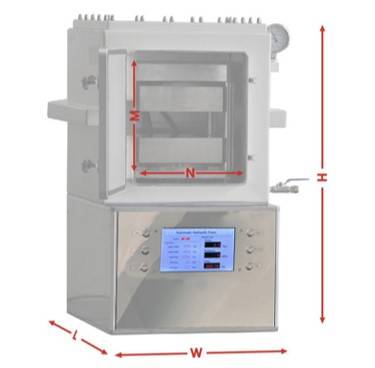

Technical specifications

| Instrument model | PPZ-600 |

|---|---|

| Pressure Range | 0-25T |

| Pressurization process | Program pressurization-program pressure-timed pressure relief |

| Pressure retention time | 1 second~0 seconds |

| Heating temperature | Up to 500℃ |

| Cooked tablet | 180x180mm,200x200mm |

| Vacuum box material | SUS 304 (stainless steel) |

| Studio size | 400x400x400mm |

| Door size | 300x350mm |

| Vacuum degree | -0.1MPa |

| Size of the whole machine | 450x550x850(LxWxH) |

| pawer supply | 220V50Hz(support110V) |

| Dimensional diagram of powder tablet press |  |

Operation steps

1.Open the hatch and place the sample in the tablet press.

2.Set the pressure and time for pressurization.

3.Adjust the heating temperature of the upper and lower heating plates.

4.Pressurize the sample to the required pressure.

5.Close the cabin door and open the vacuum pump.

6.Extract the vacuum box to the required pressure.

7.Heat the sample to the desired temperature and maintain pressure for a period of time.

8.Open the vent valve ofthe vacuum box.

9.Open the door of the vacuum box and release the pressure.

10.Open the door of the vacuum box and release the pressure

Trusted by Industry Leaders

FAQ

What Is A Lab Press?

What Are The Advantages Of Using A Hydraulically Heated Laboratory Press?

What Is The Purpose Of A Hydraulic Press In Lab?

What Does A Hydraulic Lab Heat Press Do?

What Are Different Type Of Lab Presses?

What Types Of Samples Or Materials Can Be Processed In A Hydraulically Heated Laboratory Press?

How Does A Hydraulically Heated Laboratory Press Work?

How Can The Performance Of A Hydraulically Heated Laboratory Press Be Optimized?

4.7 / 5

Incredible precision and durability. A game-changer for our lab!

4.8 / 5

Fast delivery and excellent value for money. Highly recommend!

4.9 / 5

Top-notch quality and technological advancement. Very satisfied!

4.7 / 5

Efficient and reliable. Perfect for our research needs.

4.8 / 5

Outstanding performance and low maintenance. A great investment!

4.9 / 5

Superb vacuum press power. Makes our processes much smoother.

4.7 / 5

Quick installation and easy to use. Very pleased with the purchase.

4.8 / 5

Highly responsive heating. Great for our precision requirements.

4.9 / 5

Durable and robust construction. Handles our workload effortlessly.

4.7 / 5

Excellent value. The technology is ahead of its time.

4.8 / 5

Compact design yet powerful. Ideal for our lab space.

4.9 / 5

Superior temperature control. Consistently delivers high-quality results.

4.7 / 5

Great practicality and versatility. A must-have for any lab.

4.8 / 5

Hassle-free installation. Started using it right away!

4.9 / 5

Designed for longevity. Expecting many years of reliable service.

4.7 / 5

Excellent customer service and support. Very happy with the purchase.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

The lab press for vacuum box is a specialized piece of equipment designed for laboratory use. Its main purpose is to press pills and powders according to specific requirements.

Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

The Automatic High Temperature Heat Press is a sophisticated hydraulic hot press designed for efficient temperature control and product quality processing.

Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

Enhance your lab's precision with our lab press for vacuum box. Press pills and powders with ease and precision in a vacuum environment, reducing oxidation and improving consistency. Compact and easy to use with a digital pressure gauge.

Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

Efficiently process heat-pressing samples with our Integrated Manual Heated Lab Press. With a heating range up to 500°C, it's perfect for various industries.

Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

Efficiently prepare your samples with our Automatic Heated Lab Press. With a pressure range up to 50T and precise control, it's perfect for various industries.

Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

Efficiently prepare your samples with our Split Manual Heated Lab Press. With a pressure range up to 40T and heating plates up to 300°C, it's perfect for various industries.

Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

The Manual Heat Press is a versatile piece of equipment suitable for a variety of applications, operated by a manual hydraulic system that applies controlled pressure and heat to the material placed on the piston.

Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

Efficiently prepare samples with the Electric Hydraulic Press. Compact and portable, it's perfect for labs and can work in a vacuum environment.

Anti-Cracking Press Mold for Lab Use

The anti-cracking press mold is a specialized equipment designed for molding various shapes and sizes of film using high pressure and electric heating.

Laboratory Manual Hydraulic Pellet Press for Lab Use

Efficient sample preparation with small footprint Manual Lab Hydraulic Press. Ideal for material researching labs, pharmacy, catalytic reaction, and ceramics.

kbr pellet press 2t

Introducing the KINTEK KBR Press - a handheld laboratory hydraulic press designed for entry-level users.

Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

Controlled environment lab press machine for glove box. Specialized equipment for material pressing and shaping with high precision digital pressure gauge.

Laboratory Hydraulic Press Split Electric Lab Pellet Press

Efficiently prepare samples with a split electric lab press - available in various sizes and ideal for material research, pharmacy, and ceramics. Enjoy greater versatility and higher pressure with this portable and programmable option.

Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

Reduce forming pressure & shorten sintering time with Vacuum Tube Hot Press Furnace for high-density, fine-grain materials. Ideal for refractory metals.

Vacuum Hot Press Furnace Machine for Lamination and Heating

Experience clean and precise lamination with Vacuum Lamination Press. Perfect for wafer bonding, thin-film transformations, and LCP lamination. Order now!

Ball Press Mold for Lab

Explore versatile Hydraulic Hot Press molds for precise compression molding. Ideal for creating various shapes and sizes with uniform stability.

600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

Discover the 600T Vacuum Induction Hot Press Furnace, designed for high-temperature sintering experiments in vacuum or protected atmospheres. Its precise temperature and pressure control, adjustable working pressure, and advanced safety features make it ideal for nonmetal materials, carbon composites, ceramics, and metal powders.

Laboratory Manual Hydraulic Pellet Press for Lab Use

Efficient Manure Lab Hydraulic Press with Safety Cover for sample preparation in material research, pharmacy, and electronic industries. Available in 15T to 60T.

Special Heat Press Mold for Lab Use

Square, round and flat plate forming dies for hot presses.

Related Articles

More Than Heat and Pressure: Why Your Material Bonding Fails and How to Fix It

Struggling with inconsistent results from your hot press? Discover why the root cause isn't your process but a lack of precision, and how to solve it.

Engineered Certainty: Why Your Lab Bench Isn't Made of Solid Oak

Explore the engineering of hot pressed boards like MDF and HDF, and why their stability and consistency often trump solid wood in precision environments.

Beyond Sintering: The Brutal Elegance of Hot Pressing

Explore how hot pressing forges ultra-dense materials by conquering porosity, creating components with superior strength and wear resistance.

The Physics of Permanence: How Hot Presses Forge the Modern World

Hot presses use controlled heat and pressure to create permanent bonds. Discover how this transformative technology enables everything from electronics to advanced materials.

The Unseen Physics of Perfection: Mastering Heat, Pressure, and Time

A deep dive into how hot press machines work, exploring the critical interplay of heat, pressure, and time that defines quality and prevents failure.

The Physics of Perfection: How Hot Pressing Overcomes the Limits of Sintering

Hot pressing uses intense pressure and heat to eliminate porosity, creating ultra-dense materials for critical, high-performance applications.

Density at Any Cost: The Beautiful, Flawed Process of Hot Pressing

Hot pressing delivers unmatched material density, but its high costs, slow speed, and hidden inconsistencies create a complex trade-off for engineers.

When Failure is Not an Option: The Physics of Hot Press Forging

Hot press forging trades dimensional precision for superior strength, creating complex, failure-resistant metal parts for critical applications.

Forging Perfection in a Void: The Physics of Ultra-Dense Materials

Discover how vacuum hot pressing furnaces use heat, pressure, and a pure vacuum to forge ultra-dense, high-purity advanced materials.

Beyond the Furnace: How Pressure Unlocks Ultimate Ceramic Performance

Hot pressing combines heat and pressure to overcome the limits of traditional sintering, creating near-perfectly dense ceramics with superior strength.

Why Your Lab-Scale Bonding Fails: The Hidden Physics of Heat and Pressure

Struggling with delamination or voids in your laminates and composites? Discover the root cause and how to finally achieve perfect, repeatable results.

Beyond the Furnace: How Hot Pressing Unlocks Near-Perfect Material Density

Explore how hot pressing combines heat and pressure to overcome traditional sintering, achieving superior density and strength in advanced materials.