Automatic Heated Lab Press

Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

Item Number : PPL

Price varies based on specs and customizations

- Cylinder stroke

- 80mm

- Heating temperature

- Up to 1000℃

- Sample size

- Φ10-30mm

- Pressure Range

- 0-10T

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Introduction

The Automatic heated hydraulic lab press is a sophisticated hydraulic hot press designed for efficient temperature control and product quality processing. It features advanced heating methods, including oil heating, which ensures uniform temperature distribution and minimizes heat loss, thereby reducing production costs. The press is equipped with an automated control panel, offering three heat settings for versatile applications, and is ideal for craft enthusiasts and small-scale production needs.

Applications

The Automatic high temperature heat press application is versatile and can be utilized in various fields, including industrial manufacturing, educational research, and small-scale crafting. This technology is particularly beneficial for high-volume operations, precision temperature control, and the sintering of diverse materials under controlled conditions.

- Industrial Manufacturing: Ideal for continuous imprinting of items in high-volume operations, utilizing automatic shuttle and dual platen transfer presses.

- Educational and Scientific Research: Used in laboratories for hot-press sintering experiments of nonmetal materials, carbon composite materials, ceramic materials, and metal powder materials under vacuum or protected atmospheres.

- Crafting and Small-scale Production: Suitable for craft enthusiasts, students, and housewives for producing unique and interesting items with precise temperature control and even heat distribution.

Detail & Parts

- Set:In operation interface, press the SET button to enter the interfac, and then press the SET button to move the cursor; when thecursor is moved to Die Diameter , you can press the SET button again to return to the operation interface.

- +:In operation interface, press the + button to increase the value;

- -:In operation interface, press the - button todecrease the value;

- Stop:When the equipment is running,press the STOP buttonto stop motor running and open the pressure relief valve to release the pressure.

- Release:The equipment starts running when theRELEASE button is pressed down; when the pressure exceeds the specified value or the limit switch is pressed, the equipment stops automatically and releases pressure . The operation also can be stopped manually.

- Sample:The equipment starts running when theSAMPLE button is pressed down; when the pressure exceeds the specified value, the pressurizing stops and maintains the pressure ; when the pressure is lower than the lower limit , the equipment compensates automatically; when the timing ends, the equipment releases pressure automatically

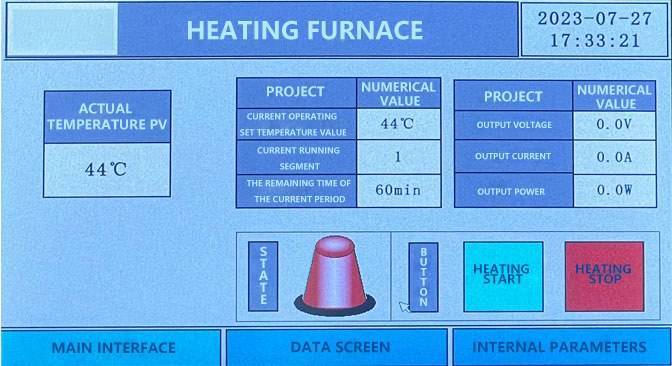

- Step 1: Select the data screen to enter the settings interface

- Step 2: Select "Program Control Section Settings"

- Step 3: There are 20 temperature control programs in the program. Select the first section.

- Step 4: Set the temperature and speed of the first section according to the experimental requirements.

- Step 5: If multiple temperature control programs are needed, you can set the 20 section program.

- Step 6: After setting, press the main interface to return to the operation interface

- Step 7: On the main interface, press "heating start".

- Step 8: The device starts to heat up according to the program.

- Step 9: The equipment will automatically stop after heating up. If the setting is incorrect, such as not reaching the set temperature within the specified time, the device will automatically terminate

Features

The Automatic high temperature heat press is a cutting-edge solution for high-volume operations, offering a range of features designed to enhance productivity, safety, and cost-efficiency. This machine stands out with its advanced heating methods, automated controls, and safety features, making it a top choice for businesses looking to streamline their production processes.

-

Advanced Heating Technology: Unlike traditional steam or electric heating methods, this heat press utilizes a heating oil method that ensures high heat capacity and uniform temperature distribution. This not only reduces heat loss but also significantly lowers production costs, ensuring optimal hot pressing results.

-

Automated Control Panel: The machine features an automated control panel that simplifies operation, allowing for single-person operation and reducing labor costs. This feature enhances efficiency and allows for precise temperature selection and technical control, crucial for maintaining product quality.

-

Safety and Energy Efficiency: Equipped with an auto shut-off feature, the machine automatically turns off after 10 minutes of inactivity, ensuring energy efficiency and safety. Additionally, it includes an insulated safety base to prevent accidental burns, making it a secure choice for busy production environments.

-

Premium Quality Construction: Built with a robust aluminum upper-heating element and capable of operating at 220v, this heat press is designed for durability and high performance. It supports continuous imprinting tasks with features like automatic shuttle and dual platen transfer, ideal for high-volume operations.

Principle

The Automatic High Temperature Heat Press operates by integrating positive pressure with negative pressure and specialized adhesive to process equipment. It features high pressure, low temperature, and brief film pressure durations, effectively minimizing workpiece deformation during processing with negative pressure equipment, thereby enhancing product quality and performance.

Advantages

The Automatic High Temperature Heat Press offers numerous advantages that enhance productivity, safety, and environmental sustainability in various industrial and craft applications. Here are some of the key benefits:

-

Enhanced Heating Efficiency: This heat press ensures uniform heating of both the internal and external surfaces of workpieces, leading to superior quality and improved adhesive curing strength. The even distribution of heat prevents excessive heat generation in the workpiece, optimizing the curing process.

-

Eco-Friendly Operation: In line with modern environmental standards, the heat press is designed to be eco-friendly, ensuring hygiene and safety while maintaining high heating efficiency. This feature is crucial for industries focusing on sustainability and regulatory compliance.

-

Advanced Automation Features: The integration of digital technology allows for precise control over heat, pressure, and timing settings. This automation not only improves the consistency and quality of the output but also reduces the risk of human error.

-

Versatile Design Options: With various design types available, such as clamshell, swing-away, and draw style presses, users can choose the most suitable configuration based on their specific needs. This versatility ensures that the heat press can be adapted to a wide range of applications.

-

Safety Enhancements: The Automatic High Temperature Heat Press includes safety features such as an insulated safety base to prevent accidental burns and an auto shut-off function after 10 minutes of inactivity. These features ensure operator safety and reduce the risk of machine-related accidents.

-

Energy Efficiency: The auto shut-off feature not only enhances safety but also contributes to energy savings by automatically turning off the machine when not in use, reducing unnecessary power consumption.

-

Premium Quality Construction: Built to withstand high temperatures and continuous use, the heat press is designed for durability and reliability, ensuring long-term performance and minimal downtime.

These advantages make the Automatic High Temperature Heat Press an essential tool for industries and crafts requiring precise and efficient heat application, while also prioritizing safety and environmental responsibility.

Technical specifications

| Instrument model | PP-900L |

| Pressure Range | 0-10T |

| Pressurization process | Program pressurization-program pressure-timed pressure relief |

| Pressure retention time | 1 second ~ oseconds |

| Cylinder stroke | 80mm |

| Heatingtemperature | Upto 1000℃ |

| Mold material | Nickel-based alloy (high temperature resistant material) |

| Sample size | Φ10-30mm |

| Mold shape | Φ50x90mm |

| The caliber of thefurnace | Φ60mm |

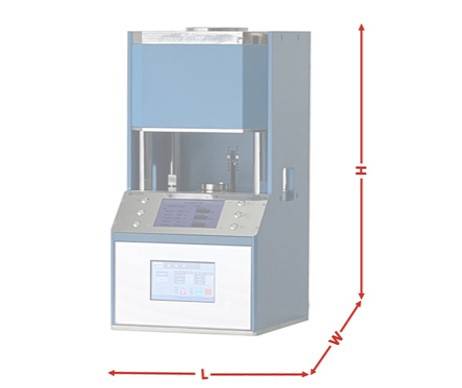

| Size of the whole machine | 400x380x780(LxWxH) |

| power supply | 220V 50Hz |

| Dimensional diagram of powder tablet press |  |

Operation steps

1.Insert the sample into the mold.

2.Putthe mold into the hot press.

3.Set the required pressure and holding time.

4.Pre press the sample well.

5.Enter the data screen, set the heating temperature and time, and set up to 20 heating programs at most.

6.Return to the main interface, click on heating to start heating.

7.After reaching the set temperature, start pressurizing.

8.Take out the sample.

Trusted by Industry Leaders

FAQ

What Is A Lab Press?

What Are The Advantages Of Using A Hydraulically Heated Laboratory Press?

What Is The Purpose Of A Hydraulic Press In Lab?

What Does A Hydraulic Lab Heat Press Do?

What Are Different Type Of Lab Presses?

What Types Of Samples Or Materials Can Be Processed In A Hydraulically Heated Laboratory Press?

How Does A Hydraulically Heated Laboratory Press Work?

How Can The Performance Of A Hydraulically Heated Laboratory Press Be Optimized?

4.7 / 5

Incredible precision and durability. A game-changer for our lab!

4.8 / 5

Fast delivery and excellent value for money. Highly recommend!

4.9 / 5

Top-notch quality and user-friendly interface. Best purchase ever!

4.7 / 5

Technologically advanced and reliable. Perfect for high-volume tasks.

4.8 / 5

Ergonomic design and efficient heating modes. A must-have for labs!

4.9 / 5

Superb build quality and safety features. Very impressed!

4.7 / 5

Quick setup and easy operation. Great for our research needs.

4.8 / 5

Outstanding performance and energy efficiency. Very satisfied!

4.9 / 5

Impressive automation and control. A significant upgrade for our lab.

4.7 / 5

Durable and versatile. Handles all our heat press needs flawlessly.

4.8 / 5

Excellent support and quick delivery. Highly reliable product!

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

30T 40T Split Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

Discover our split automatic heated lab press 30T/40T for precise sample preparation in material research, pharmacy, ceramics, and electronics industries. With a small footprint and heating up to 300°C, it's perfect for processing under vacuum environment.

Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

Efficiently prepare your samples with our Automatic Heated Lab Press. With a pressure range up to 50T and precise control, it's perfect for various industries.

Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

The Manual Heat Press is a versatile piece of equipment suitable for a variety of applications, operated by a manual hydraulic system that applies controlled pressure and heat to the material placed on the piston.

Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

Enhance your lab's precision with our lab press for vacuum box. Press pills and powders with ease and precision in a vacuum environment, reducing oxidation and improving consistency. Compact and easy to use with a digital pressure gauge.

Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

Efficiently process heat-pressing samples with our Integrated Manual Heated Lab Press. With a heating range up to 500°C, it's perfect for various industries.

Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

The lab press for vacuum box is a specialized piece of equipment designed for laboratory use. Its main purpose is to press pills and powders according to specific requirements.

Electric Heated Hydraulic Vacuum Heat Press for Lab

The Electric Vacuum Heat Press is a specialized heat press equipment that operates in a vacuum environment, utilizing advanced infrared heating and precise temperature control for high quality, rugged and reliable performance.

Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

Efficiently prepare your samples with our Split Manual Heated Lab Press. With a pressure range up to 40T and heating plates up to 300°C, it's perfect for various industries.

Special Heat Press Mold for Lab Use

Square, round and flat plate forming dies for hot presses.

Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

Experience efficient sample preparation with our Automatic Lab Press Machine. Ideal for material research, pharmacy, ceramics, and more. Features a compact size and hydraulic press functionality with heating plates. Available in various sizes.

Laboratory Manual Hydraulic Pellet Press for Lab Use

Efficient sample preparation with small footprint Manual Lab Hydraulic Press. Ideal for material researching labs, pharmacy, catalytic reaction, and ceramics.

Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

Controlled environment lab press machine for glove box. Specialized equipment for material pressing and shaping with high precision digital pressure gauge.

Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

Fast and easy xrf sample pellet preparation with KinTek Automatic Lab Pellet Press. Versatile and accurate results for X-ray fluorescence analysis.

kbr pellet press 2t

Introducing the KINTEK KBR Press - a handheld laboratory hydraulic press designed for entry-level users.

Laboratory Manual Hydraulic Pellet Press for Lab Use

Efficient Manure Lab Hydraulic Press with Safety Cover for sample preparation in material research, pharmacy, and electronic industries. Available in 15T to 60T.

Vacuum Hot Press Furnace Machine for Lamination and Heating

Experience clean and precise lamination with Vacuum Lamination Press. Perfect for wafer bonding, thin-film transformations, and LCP lamination. Order now!

Ball Press Mold for Lab

Explore versatile Hydraulic Hot Press molds for precise compression molding. Ideal for creating various shapes and sizes with uniform stability.

Laboratory Hydraulic Press Lab Pellet Press for Button Battery

Efficiently prepare samples with our 2T Button Battery Press. Ideal for material research labs and small-scale production. Small footprint, lightweight, and vacuum-compatible.

Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

Efficiently prepare samples with the Electric Hydraulic Press. Compact and portable, it's perfect for labs and can work in a vacuum environment.

Related Articles

More Than a Squeeze: The Physics and Psychology of the Hydraulic Hot Press

An insight into the hydraulic hot press, where Pascal's Law meets thermodynamics to reshape materials. A story of force, heat, and control.

Precision Under Pressure: The Physics and Psychology of the Hydraulic Hot Press

Discover how the synergy of heat and pressure in a hydraulic hot press transforms materials, guided by the elegant physics of Pascal's Law.

The Physics of Flawless Materials: Deconstructing the Hydraulic Hot Press

Discover how the synergy of Pascal's Law and thermal energy in a hydraulic hot press enables precise, repeatable material bonding and forming.

Why Your Composite and Polymer Parts Keep Failing: The Secret Is Simultaneous Heat and Pressure

Struggling with inconsistent composite or polymer bonding? Discover why separate heating and pressing fails and how a hot hydraulic press ensures repeatable, high-quality results.

Pressure and Heat: Forging Certainty into Matter

A hot press doesn't just shape materials; it eliminates hidden flaws and forges atomic-level trust. Learn the physics of material integrity.

Why Your Molded Parts Fail: The Hidden Truth About Heat and Pressure

Struggling with warped or inconsistent parts? Learn why pressure isn't the problem and how precise thermal control in a hydraulic press is the key.

Force and Fire: A Guide to Material Transformation with Hot and Cold Pressing

Hot and cold pressing aren't just about temperature; they are different philosophies of material creation. Learn when to use force vs. force and fire.

Optimizing Laboratory Analysis with Split Automatic Heated Lab Pellet Press

Explore the advanced features and benefits of split automatic heated lab pellet presses for precise pellet preparation in various analytical applications. Ideal for high-throughput laboratories.

Why Your Molding & Curing Results Are Inconsistent—And How to Fix It

Frustrated with warped parts and failed molding? Discover the hidden reason your hydraulic press may be the problem and how the right tool ensures consistent results.

Beyond Brute Force: The Controlled Physics of Perfect Material Bonding

A hot press isn't just a heater and a press. It's a system where controlled heat and force unite for flawless, repeatable material bonding.

Manual Lab Hydraulic Pellet Press: Comprehensive Guide to High-Quality Pellet Preparation

Explore the detailed guide on using a Manual Lab Hydraulic Pellet Press for high-quality pellet preparation in spectral analyses. Learn about features, operation, and maintenance for optimal performance.

Understanding Hot Presses and Safety Considerations

An overview of hot presses, their applications, advantages, and safety precautions.