The Controlled Chaos of the Lab

A laboratory is a place of paradox. It is a space of immense creativity and potential chaos, yet it demands absolute control and precision. A beaker of acid is knocked over. A sharp instrument is scraped across a benchtop. A sensitive culture requires a perfectly sterile environment.

In this high-stakes environment, the surfaces we work on are not passive bystanders. They are active participants. They are the first line of defense against accidents, the foundation for reproducible results, and the unseen guardians of safety and sterility. The choice of material for a lab bench is not an aesthetic decision; it's a functional one with deep consequences.

More Than a Surface: A Fused Guardian

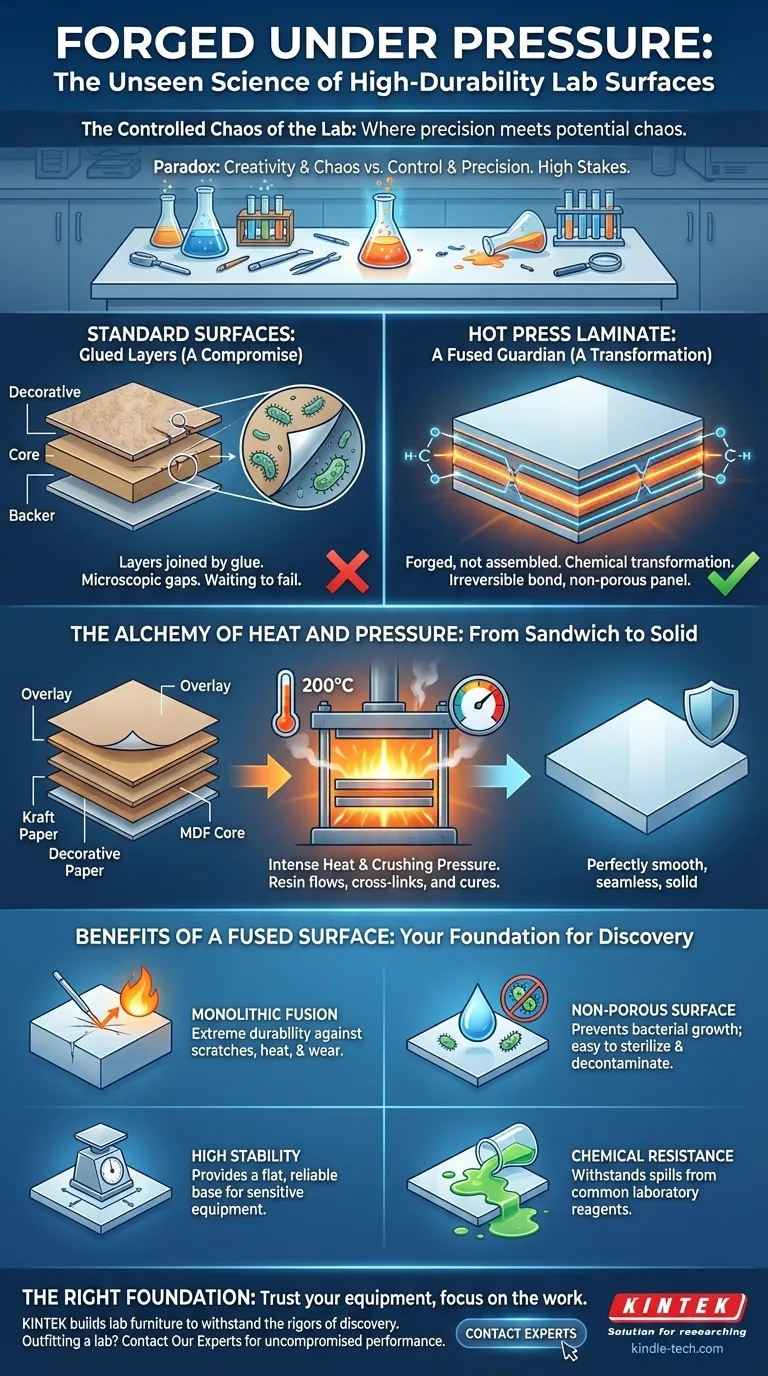

Many surfaces are simply layers held together by glue. They look solid, but at a microscopic level, they are a compromise waiting to fail. Hot press laminate is different. It's born from a more violent and definitive process.

At its core, it is a material forged, not assembled. Layers of resin-impregnated paper are fused to a rigid substrate under immense heat and pressure. This isn’t adhesion; it’s a chemical transformation. The process creates an irreversible bond, turning separate layers into a single, monolithic, and non-porous panel.

It’s the difference between stacking bricks and casting concrete. One is a collection of parts; the other is a unified whole.

The Alchemy of Heat and Pressure

The process is an act of industrial alchemy, transforming simple components into something far stronger.

-

The Components: It begins with a "sandwich." A stable core of MDF or particleboard provides the structure. This is topped with decorative paper (for aesthetics) and impact-resistant Kraft paper, all saturated with thermosetting melamine resins.

-

The Forge: The sandwich is placed into a press where it is subjected to intense heat (up to 200°C) and crushing pressure.

-

The Transformation: The heat and pressure trigger a molecular chain reaction. The resin flows and then cures, cross-linking to form a single, incredibly hard, and seamless surface that is permanently fused to its core. The result is a material that is fundamentally new.

The Psychological Comfort of an Engineered Surface

The properties of this fused surface provide a profound psychological benefit to the user in a lab setting: peace of mind. You can trust it, allowing you to focus on the work that matters.

Resilience as a Default State

The cured melamine surface is relentlessly durable. It shrugs off the scratches, stains, and heat that are daily realities in a research environment. This isn't a delicate surface to be coddled; it’s a workhorse engineered for abuse. This ruggedness allows scientists to work with confidence, not fear.

The Enemy of Contamination

Because the lamination process creates a completely sealed, non-porous finish, there are no microscopic crevices for chemicals or bacteria to hide. This is its superpower in a lab. A surface that can be wiped clean isn't just a convenience; it is a prerequisite for sterile work and easy decontamination. It’s a bulwark against the invisible threats of contamination.

Predictability in a World of Variables

Scientific experiments are about controlling variables. A warped or unstable work surface is an unacceptable variable. The fused panel construction of hot press laminate provides exceptional stability, resisting warping and staying perfectly flat over time. For sensitive equipment and precise measurements, this reliability is non-negotiable.

Why Industrial Constraints Create the Perfect Lab Material

Hot press lamination is an industrial process. It cannot be done on-site. This seeming limitation is actually its greatest strength.

The factory setting ensures absolute control over the heat, pressure, and curing time. This guarantees a level of consistency and quality that on-site applications could never achieve. While its rigidity makes it unsuitable for complex curves, laboratories thrive on functional, flat, and stable planes. The form perfectly follows the function of scientific inquiry.

| Feature | Laboratory Benefit |

|---|---|

| Monolithic Fusion | Extreme durability against scratches, heat, and wear. |

| Non-Porous Surface | Prevents bacterial growth; easy to sterilize & decontaminate. |

| High Stability | Provides a flat, reliable base for sensitive equipment. |

| Chemical Resistance | Withstands spills from common laboratory reagents. |

The Right Foundation for Discovery

In the end, a lab bench is more than furniture. It is a critical piece of scientific equipment. Its reliability directly impacts the integrity of the work conducted upon it. For environments where durability, hygiene, and chemical resistance are paramount, the choice is clear. The forged, fused, and stable nature of hot press laminate surfaces makes them the unequivocal standard.

At KINTEK, we understand that the foundation of great research is equipment you can trust. That's why we build our laboratory furniture and work surfaces to withstand the rigors of discovery, providing the stability and resilience your work demands. If you are outfitting a lab where performance cannot be compromised, Contact Our Experts.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Double Plate Heating Press Mold for Lab

Related Articles

- Comprehensive Guide to Heat Press Machines

- WIP – Warm Isostatic Press Equipment: Design, Features, and Benefits

- Comprehensive Guide to Hydraulic Hot Press: Function, Features and Applications

- The Physics of Permanence: How Hot Presses Forge the Modern World

- A Comprehensive Guide to Hot Press Machines: Functionality, Application, Features, Principles, Classification, and Technical Requirements