Introduction

Table of Contents

Welcome to our comprehensive guide to heat press machines! Whether you're a business professional or a hobbyist, understanding the world of heat presses can be a game-changer. In this guide, we'll walk you through everything you need to know about heat presses, from their definition and uses to the different types of machines available in the market. We'll also explore the various design types and construction elements that make up a heat press. By the end of this guide, you'll be equipped with the knowledge to choose the best heat press for your needs and take your projects to the next level. So, let's dive in!

Definition and Uses of a Heat Press

Understanding the function of a heat press

A heat press is a machine designed to imprint a design or graphic on a substrate, such as a t-shirt, using heat and pressure for a specific duration. It is not limited to fabric applications; specialized heat presses can also imprint designs on mugs, plates, jigsaw puzzles, caps, and other products. Essentially, a heat press heats and presses materials, making it a valuable and versatile tool for any printing business.

Diverse applications of heat presses on different substrates

Sublimation

Heat presses can be used for sublimation printing, a method that involves using specialized inks printed onto paper via a transfer. This transfer is then heat pressed onto a poly-coated substrate or a polyester garment. Sublimation printing offers various uses and benefits and is commonly used for customizing garments and other polyester-based products.

Vinyl

Heat presses are also commonly used for applying vinyl designs onto garments. This method is often used for printing names and numerals on sports t-shirts and other clothing items. There are different types of heat presses available, each suitable for specific applications and substrates. Some heat presses are designed for t-shirt fronts, hats, tagless labels, and even large format prints like signs or art prints.

Overall, heat presses offer a wide range of uses and can be adapted to various substrates. They provide reliable, professional results that can last for the lifetime of the garment or product. Heat presses are essential equipment for printing businesses, allowing for new product channels and increased functionality.

Types of Heat Press Machines

Introduction to manual and automatic heat presses

Both manual and automatic heat presses are widely available. A manual heat press requires manual closing and opening of the press, while an automatic heat press has an automatic, electromagnetic opening. Manual heat presses are generally more affordable and suitable for small-scale operations. Automatic heat presses are more efficient and faster, making them ideal for high-volume production.

Insights on the new semi-automatic heat press

A new style of heat press, known as the semi-automatic heat press, has entered the market. These machines offer a combination of manual closing and automatic opening. This design allows for easier operation and increased productivity. With the semi-automatic heat press, users can manually close the press and let the machine automatically open after the desired heat and pressure are applied.

Role of digital technology in modern heat press machines

Digital technology has revolutionized heat press machines, enabling precise control of heat, pressure levels, and timing. Newer machines feature digital displays and controls that allow users to set and monitor the temperature and pressure accurately. This technology ensures consistent and high-quality results, making it easier for businesses to achieve professional-looking prints.

Different types of heat press designs

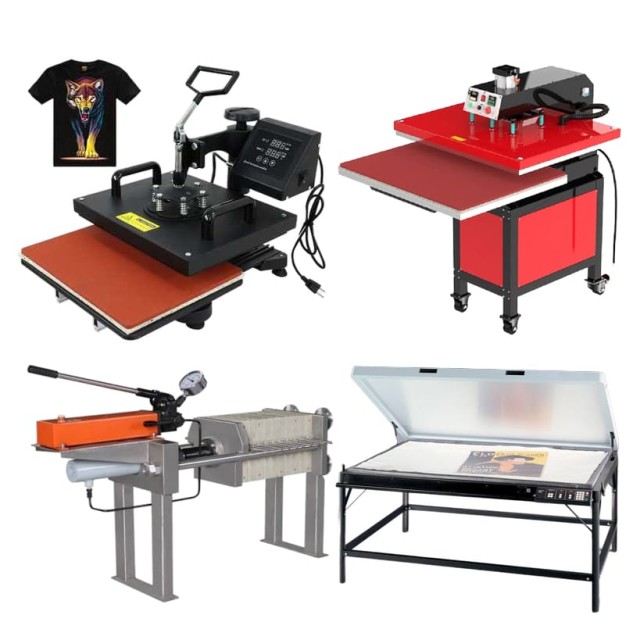

The most common types of heat press machines employ a flat platen to apply heat and pressure to the substrate. Here are a few design variations:

-

Clamshell design: In this design, the upper heat element opens like a clamshell, providing easy access to the lower platen. It is a popular choice due to its compact size and ease of use.

-

Swing-away design: The heat platen swings away from the lower platen in this design. This allows for more space and flexibility when placing and removing garments or other substrates. It also reduces the risk of accidental burns.

-

Draw style press: This design allows the bottom platen to be pulled out like a drawer. This feature makes it convenient to prepare the graphic or substrate before applying heat and pressure.

-

Vacuum press: Vacuum presses utilize air pressure to provide the necessary force for heat transfer. They can achieve high psi ratings, making them suitable for demanding applications.

Choosing the right heat press machine

When selecting a heat press machine, consider the following factors:

-

Substrate compatibility: Different heat presses work best for specific substrates. Some are suitable for t-shirts, hats, tagless labels, or large format prints. Ensure that the machine you choose matches your customization needs.

-

Functionality and features: Look for heat presses with swappable lower platens, as they allow for printing on various items. Consider additional features like digital controls, adjustable pressure, and temperature settings for enhanced customization options.

Remember, the right heat press machine will depend on your specific requirements and the types of items you plan to customize. Take the time to research and choose a reliable machine that fits your business needs.

Design Types of Heat Press

Understanding the 'clamshell' design

The "clamshell" design is one of the most common types of heat press. In this design, the upper heat element of the press opens and closes like a clamshell. This design is popular because it takes up less space and is easy to use. It is ideal for flat substrates like t-shirts and bags.

Exploration of the 'swing-away' design

The "swing-away" design is another popular type of heat press. In this design, the heat platen swings away from the lower platen. This design allows for easier access to the lower platen, making it easier to place and remove substrates. It is ideal for substrates that require precise positioning, such as hats and mugs.

Discussion on 'draw style press' design

The "draw style press" design is a unique type of heat press. In this design, the bottom platen can be pulled out like a drawer away from the heat for preparation of the graphic. This design is beneficial for substrates that require pre-pressing or positioning before applying heat, such as large art prints or signs.

Introduction to vacuum presses

Vacuum presses are a specialized type of heat press that utilize air pressure to provide the necessary force for pressing. These presses can achieve high psi ratings, making them suitable for substrates that require a high level of pressure, such as coated metal blanks. Vacuum presses are also commonly used for 3D sublimation printing.

Everything You Need to Know About A Heat Press

What exactly is a heat press machine?

A heat press machine is a type of equipment that uses heat and pressure to apply designs onto various substrates. It consists of an upper platen and a lower platen, with the heat being generated by the upper platen.

How does a heat press work?

A heat press works by applying a transfer under pressure and at a high temperature for a pre-set amount of time. The heat and pressure allow the design to adhere to the substrate, creating a permanent bond. This results in a professional and long-lasting application.

Classification of heat presses

Heat presses can be classified into various types based on their functionality and medium of application. Some common classifications include thermostatic heat presses, pulse heat presses, duplex heat presses, dual head pulse heat presses, benchtop heat presses, and swing-away heat presses. Each type has its own advantages and is suitable for different applications.

Choosing the right heat press

When choosing a heat press, consider the substrates you will be customizing. There are presses specifically designed for t-shirts, hats, tagless labels, and even large art prints. It is also important to consider the size, configuration, and features of the heat press. Many heat presses offer swappable lower platens, allowing for customization of various substrates.

Designing artwork for a heat press

Designing artwork for a heat press involves using software like Adobe Illustrator or CorelDraw to create and process graphics. Different transfer manufacturers may have specific requirements for file types and colors. It is important to follow these guidelines to ensure the best results.

In conclusion, heat presses come in various designs, each with its own advantages and applications. Understanding the different types of heat presses and selecting the right one for your needs is crucial for achieving high-quality and professional results.

Heat Press Construction and High-Volume Operations

Structure of the upper-heating element

Most heat presses currently on the market use an aluminium upper-heating element with a heat rod cast into the aluminium or a heating wire attached to the element. This design ensures efficient heat transfer and durability for high-volume operations.

Understanding automatic shuttle and dual platen transfer presses

For high-volume operations involving the continuous imprinting of items, automatic shuttle and dual platen transfer presses are used. These presses are ideal for businesses that require fast and efficient heat pressing. The substrates to be imprinted are continuously loaded onto the lower platen and shuttled under the heat platen, which then applies the necessary heat and pressure. This automation allows for increased productivity and reduces manual labor.

Insights into high-volume operations

In high-volume operations, it is crucial to have heat presses that can handle the demands of continuous imprinting. Digital technology in newer machines enables precise control of heat and pressure levels and timing. This ensures consistent and high-quality results. Additionally, many heat presses feature swappable lower platens, allowing for customization of various substrates such as t-shirts, hats, tagless labels, and more.

Overall, heat press construction and high-volume operations go hand in hand. The structure of the upper-heating element in heat presses ensures efficient heat transfer and durability. Automatic shuttle and dual platen transfer presses are ideal for high-volume operations, offering automation and increased productivity. Understanding the different options available and choosing the right heat press for your needs is crucial for achieving consistent and high-quality results in your customization business.

Overview of the best heat press options in the current market

When choosing the best heat press machine, several factors come into play. It heavily depends on what you plan to produce and sell. Consider the following characteristics that are universally good for business uses:

-

Heat Plate Size: The size of the heat plate determines the maximum printing area. Make sure to choose a heat press with a plate size that suits your needs.

-

Even Heat: Look for a heat press that provides even heat distribution across the entire plate. This ensures consistent and high-quality prints.

-

Heat Settings: A heat press with adjustable heat settings allows you to customize the temperature based on the material you're working with. This flexibility ensures optimal results.

-

Price: Consider your budget when selecting a heat press. While quality and features are important, it's essential to find a machine that offers the best value for your money.

Overall, a heat press machine is a valuable investment for expanding your business or indulging in creative hobbies. The customization options it offers are vast, and with a professional-grade machine, you can expect a return on your investment for decades to come.

Conclusion

In conclusion, heat press machines have revolutionized the world of garment decoration and customization. With their versatility and efficiency, they have become an essential tool for businesses in various industries. Whether you're in the fashion industry, creating promotional products, or starting your own t-shirt printing business, a heat press machine can greatly enhance your productivity and profitability. From manual to automatic and digital technology advancements, the options available in the market cater to different needs and budgets. So, if you're looking to take your business to the next level, investing in a high-quality heat press machine is definitely worth considering.

If you are interested in this product you can browse our company website:https://kindle-tech.com/product-categories/heated-lab-press, we always insist on the principle of quality first. During the production process, we strictly control every step of the process, using high quality materials and advanced production technology to ensure the stability and durability of our products. to ensure that their performance meets the highest standards. We believe that only by providing customers with excellent quality can we win their trust and long-term cooperation.

Related Products

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Manual Lab Heat Press

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press