Manual Lab Press

Manual Lab Heat Press

Item Number : PCHP

Price varies based on specs and customizations

- Pressure range

- 0-30T

- Temperature control accuracy

- 0.1℃

- Max temperature

- Room temperature -800 °C

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Applications

Manual hydraulic presses are mainly used in laboratories for various applications such as forging, molding, stamping, riveting and other operations. It allows the creation of complex shapes while saving material.

Frequency of use is an important factor to consider when deciding to use a manual hydraulic press. If the press is not used regularly, manual operation will not cause much inconvenience. However, if the press needs to be used frequently, it can become labor-intensive due to the physical strength required to operate it.

The use of manual hydraulic presses in the laboratory depends on factors such as cost, frequency of use, and the level of repeatability required. It may be a suitable option for laboratories with limited budgets and infrequent use, but may not be ideal for workflows that require high precision and consistent results.

Feature

The parts of a manual hydraulic press include:

- Mainframe: The mainframe provides the structure and support for the press.

- Safety Door: The safety door is a correction gate that ensures safe operation and prevents accidents.

- Limit Switch: The limit switch limits the amount of movement past a certain point, providing control over the press's operation.

- Manual Control Valve: The manual control valve allows for manual control of the press's operation, such as adjusting the pressure or speed.

- Relief Valve: The relief valve controls the hydraulic pressure by regulating the flow of hydraulic fluid. It ensures that the press does not exceed the desired pressure level.

- Pressure Gauge: The pressure gauge gives a reading of the hydraulic pressure, allowing the operator to monitor and adjust the pressure as needed.

- Hydraulic Cylinder: The hydraulic cylinder applies unidirectional stroke force to the press. It is responsible for generating the force needed to press materials.

- Oil Tank: The oil tank stores the hydraulic fluid, which is essential for the operation of the press. The hydraulic fluid is pumped into the cylinders to generate the necessary force.

- Pressing Plate: The pressing plate is the component that applies pressure to the workpiece. It is attached to the hydraulic cylinder and moves up and down to exert force on the material being pressed.

These are the main components of a manual hydraulic press. It is important to note that manual hydraulic presses require physical effort from the operator to operate, making them harder to use consistently for each task compared to automatic hydraulic presses.

Detail & Parts

Technical specifications

The main technical parameters are different

| Product model | PCHP-600C | PCHPH-600C |

|---|---|---|

| Pressure range | 24T | 24T |

| Temperature control range | Room temperature -800 °C | Room temperature -600 °C |

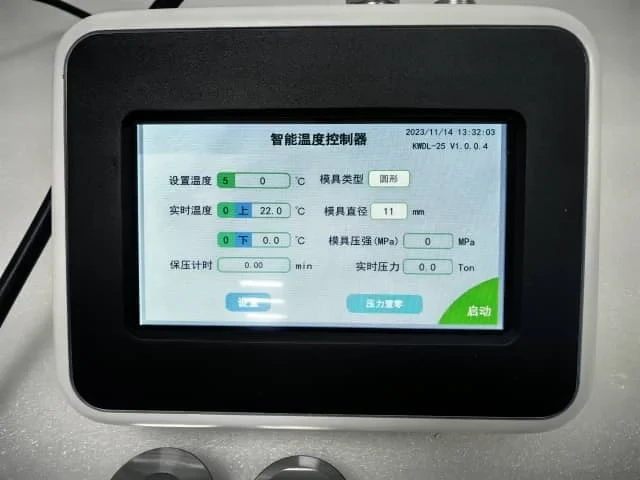

| Temperature control method | The intelligent 5-stage adjustable continuous temperature control and different holding time can be set | 1 stage of temperature control and heat preservation time |

| Mold heating range | Room temperature -300 °C | Room temperature -300 °C |

| Mold size | 100*100mm | 100*100mm |

| Temperature control accuracy | 0.1℃ | 0.1℃ |

| Real-time vs. actual temperature | ±1℃ | Unknown |

| Temperature calibration | Self-calibrating | not |

| Pressure control accuracy | 0.1T [can be customized and set by yourself] | 0.1T |

| Display mode and settings | 7-inch touch LCD screen, click to enter the setting value directly, and the brightness of the screen can be adjusted | The setting can only be set by continuously clicking the button on the side of Pingmu |

| Mold pressure conversion | The program automatically converts/directly displays the pressure on the sample (Mpa) | not |

| Heating safety tips | After heating, the real-time temperature of the mold is displayed and attention is paid to prevent soup | not |

| Data management | It can be managed, stored, and viewed | not |

Main technical indicators

|

Product model

|

PCHP-600D1 | PCHP-600D2 | PCHP-600DG1 | PCHP-600DG2 |

|---|---|---|---|---|

|

Pressure range

|

0-30T | 0-30T | ||

|

Cylinder diameter

|

Ф110mm | Ф110mm | ||

| Cylinder stroke | 30mm | 30mm | ||

| The temperature control range of the intelligent thermostat | Room temperature -800 °C | Room temperature -800 °C | ||

| Intelligent thermostat temperature control mode | 5 levels of adjustable continuous temperature control | 5 levels of adjustable continuous temperature control | ||

| Mold heating range | Room temperature -300 °C | Room temperature -300 °C | ||

| Mould size: | 180*180mm | 200*200mm | 180*180mm | 200*200mm |

| Temperature control accuracy | 0.1℃ | 0.1℃ | ||

| Pressure control accuracy |

0.1T [can be customized and set by yourself]

|

0.1T [can be customized and set by yourself]

|

||

| Dwell time | Unlimited time (manual pressure relief) | Unlimited time (manual pressure relief) | ||

| How it is displayed | 7 inch touch LCD screen | 7 inch touch LCD screen | ||

| Mold pressure conversion | The program automatically converts/directly displays the pressure on the sample (Mpa) | The program automatically converts/directly displays the pressure on the sample (Mpa) | ||

| Heating safety tips | The program automatically converts/directly displays the pressure on the sample (Mpa) | The program automatically converts/directly displays the pressure on the sample (Mpa) | ||

| Data management | It can be managed, stored, and viewed | It can be managed, stored, and viewed | ||

| Device power | 220V(50Hz/60Hz) | 220V(50Hz/60Hz) | ||

Advantages

- One advantage of using a manual hydraulic press in a laboratory is its cost-effectiveness. Manual presses are typically less expensive than their automatic counterparts, as they do not require electronic power.

- A manual hydraulic press can be a cost-effective addition to a laboratory setup, especially for infrequent use. It can still provide the necessary force for sample preparation and other applications.

Trusted by Industry Leaders

4.9 / 5

This Manual Lab Heat Press is a game-changer for my lab. It's so easy to use and has helped us improve the efficiency of our sample preparation process.

4.8 / 5

I'm so impressed with the quality of this press. It's built to last and has all the features I need for my research.

4.7 / 5

The customer service at KINTEK SOLUTION is top-notch. They were very helpful in answering my questions and ensuring that I got the right press for my needs.

4.9 / 5

This press is a great value for the price. It's affordable and has all the features I need for my lab.

4.8 / 5

I'm very happy with my purchase of this Manual Lab Heat Press. It's a great addition to my lab and has helped me improve the quality of my research.

4.9 / 5

This press is easy to use and has helped me save time in my lab. I highly recommend it to other researchers.

4.7 / 5

I'm so glad I bought this Manual Lab Heat Press. It's a great tool for my lab and has helped me improve the efficiency of my research.

4.8 / 5

This press is a great investment for my lab. It's durable and has all the features I need for my research.

4.9 / 5

I'm very impressed with the quality of this press. It's built to last and has all the features I need for my research.

4.7 / 5

This press is easy to use and has helped me save time in my lab. I highly recommend it to other researchers.

4.8 / 5

I'm so glad I bought this Manual Lab Heat Press. It's a great tool for my lab and has helped me improve the efficiency of my research.

4.9 / 5

This press is a great investment for my lab. It's durable and has all the features I need for my research.

4.7 / 5

I'm very impressed with the quality of this press. It's built to last and has all the features I need for my research.

4.8 / 5

This press is easy to use and has helped me save time in my lab. I highly recommend it to other researchers.

4.9 / 5

I'm so glad I bought this Manual Lab Heat Press. It's a great tool for my lab and has helped me improve the efficiency of my research.

4.7 / 5

This press is a great investment for my lab. It's durable and has all the features I need for my research.

4.8 / 5

I'm very impressed with the quality of this press. It's built to last and has all the features I need for my research.

4.9 / 5

This press is easy to use and has helped me save time in my lab. I highly recommend it to other researchers.

4.7 / 5

I'm so glad I bought this Manual Lab Heat Press. It's a great tool for my lab and has helped me improve the efficiency of my research.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Electric Heated Hydraulic Vacuum Heat Press for Lab

The Electric Vacuum Heat Press is a specialized heat press equipment that operates in a vacuum environment, utilizing advanced infrared heating and precise temperature control for high quality, rugged and reliable performance.

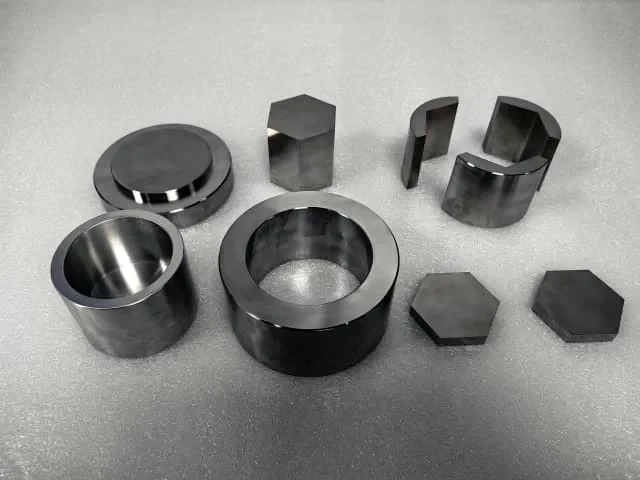

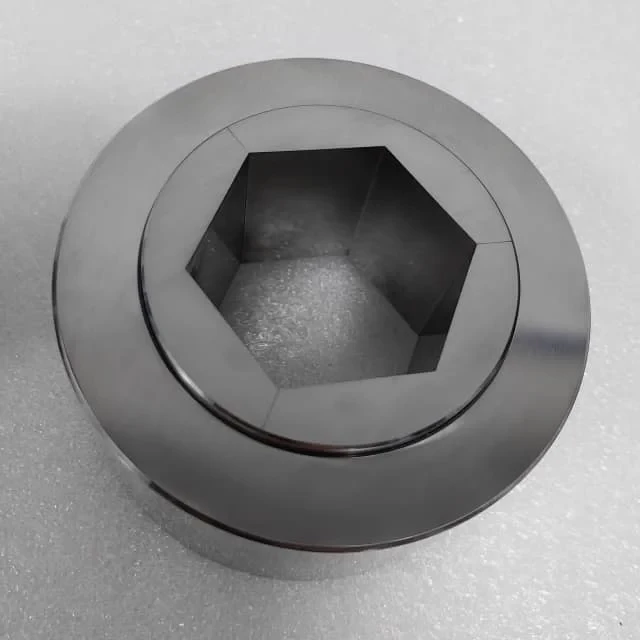

Double Plate Heating Press Mold for Lab

Discover precision in heating with our Double Plate Heating Mold, featuring high-quality steel and uniform temperature control for efficient lab processes. Ideal for various thermal applications.

Anti-Cracking Press Mold for Lab Use

The anti-cracking press mold is a specialized equipment designed for molding various shapes and sizes of film using high pressure and electric heating.

Special Heat Press Mold for Lab Use

Square, round and flat plate forming dies for hot presses.

Rubber Vulcanizer Vulcanizing Machine Plate Vulcanizing Press for Lab

The Plate vulcanizing press is a kind of equipment used in the production of rubber products, mainly used for the vulcanization of rubber products. Vulcanization is a key step in rubber processing.

Assemble Lab Cylindrical Press Mold

Get reliable and precise molding with Assemble Lab Cylindrical Press Mold. Perfect for ultra-fine powder or delicate samples, widely used in material research and development.

Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

Hydraulic diaphragm lab press filter is one type lab scale filter press, it takes small footprint, and higher pressing power.

600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

Discover the 600T Vacuum Induction Hot Press Furnace, designed for high-temperature sintering experiments in vacuum or protected atmospheres. Its precise temperature and pressure control, adjustable working pressure, and advanced safety features make it ideal for nonmetal materials, carbon composites, ceramics, and metal powders.

Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

The air pressure sintering furnace is a high-tech equipment commonly used for the sintering of advanced ceramic materials. It combines vacuum sintering and pressure sintering techniques to achieve high-density and high-strength ceramics.

Special Shape Press Mold for Lab

Discover high-pressure special shape press molds for diverse applications, from ceramics to automotive parts. Ideal for precise, efficient molding of various shapes and sizes.

Ring Press Mold for Lab Applications

Ring Press Dies, also known as Circular Pellet Press Die Sets, are integral components in various industrial and laboratory processes.

No Demolding Lab Infrared Press Mold for Laboratory Applications

Effortlessly test your samples with no demolding required using our lab infrared press mold. Enjoy high transmittance and customizable sizes for your convenience.

Related Articles

Applications and Importance of Hydraulic Press in Laboratories

A hydraulic press is a machine that uses the pressure generated in a confined fluid to configure metals, plastics, rubber, and other materials. Its operation is governed by Pascal’s principle, which states that pressure applied to a confined fluid is transmitted unaltered throughout the fluid.

Hydraulic Presses vs. Mechanical Presses Which is Right for Your Laboratory

Hydraulic and mechanical presses are two commonly used types of presses, each with its own set of advantages and disadvantages. Hydraulic presses use hydraulic cylinders to apply force, while mechanical presses use a mechanical lever or cam to apply force.

The Science Behind Hydraulic Presses and Their Applications

Hydraulic presses are machines that use hydraulic pressure to compress, mold, or shape a material. The basic concept of hydraulic presses is Pascal’s principle, which states that a pressure applied to an enclosed fluid is transmitted uniformly in all directions.

Comprehensive Guide to Hydraulic Hot Press: Function, Features and Applications

Hydraulic hot press is equipped with advanced electronic controls that allow for precise temperature selection and technical control. This enables the machine to automatically carry out processes such as stage temperature adjustment and film pressure control.

What is lab hydraulic press

A lab hydraulic press is a machine that uses a fluid to generate a force. The force is generated by a piston that is moved by the fluid. The fluid can be water, oil, or a synthetic fluid. The force generated by the press can be used to compress a variety of materials.

Understanding the Importance and Applications of Laboratory Presses

Laboratory presses play a vital role in various industries, providing precision and consistency in demanding operations. These versatile machines are used for testing, compacting, and molding materials in sectors such as pharmaceutical, laminating, rubber, and plastic molding. Whether it's for R&D, limited production, or lean manufacturing, laboratory presses offer durability and rigorous demand fulfillment.

An Insight into Hydraulic Presses: Versatility, Efficiency, and Industrial Applications

Hydraulic presses have become an integral part of various industries due to their versatility and efficiency. These powerful machines utilize hydraulic systems to generate force, allowing them to perform a wide range of industrial applications effectively. From metalworking and plastics processing to woodworking, hydraulic presses play a crucial role in numerous industrial processes.

Understanding Hydraulic Pellet Press: Working Mechanism and Applications

A hydraulic press, also known as a Bramah press, is a machine that uses fluid pressure to generate a force. This force can be used to compress or mold materials. Hydraulic presses are commonly used in manufacturing and industrial applications due to their ability to exert a large amount of force while still being easy to operate.

Comprehensive Guide on Pellet Press Dies and Their Applications

Circular Pellet Press Die Sets are essential tools used to create round pellets with precise diameters. These die sets are designed to accommodate pellets ranging from very thin to over 2 inches in length. The meticulous machining and use of high-quality materials make these die sets the best in the market.

Automatic Hydraulic Press: The Ultimate Guide for Efficient Sample Preparation and Industrial Processes

Discover the world of automatic hydraulic presses, from their versatile applications in industrial XRF and laboratory sample manipulation to their role in large-scale manufacturing, hot embossing, laminating, and polymer melting. Learn about their benefits, features, and how they revolutionize sample preparation and industrial processes.

Comprehensive Guide to Manual Hydraulic Pellet Press

A manual hydraulic pellet press is a valuable tool in the laboratory for preparing pellets with a smooth and homogeneous surface for spectral analyses. It is commonly used in applications such as X-ray fluorescence analysis or infrared spectroscopy for elemental analysis.

How to choose a laboratory hot press

The laboratory hot pressing machine is suitable for laboratory users who are strict about sample pressing temperature, pressure control accuracy and need a wide size mold for pressing samples. The new lab hot press of KINDLE TECH has a double-plate structure and a pressing force of 0~40 tons.