Function of Hydraulic Hot Press

Table of Contents

- Function of Hydraulic Hot Press

- Temperature selection and technical control

- Processing of product quality

- Traditional heating methods: steam heating and electric heating

- Issues with traditional methods: non-uniform temperature, high power consumption, operating costs

- Introduction of heating oil heating method

- Benefits: high heat capacity, uniform temperature, low heat loss, reduced production cost, desired hot pressing effect

- Features of Hydraulic Hot Press

- Applications of Hydraulic Hot Press

Temperature selection and technical control

Hydraulic hot press is equipped with advanced electronic controls that allow for precise temperature selection and technical control. This enables the machine to automatically carry out processes such as stage temperature adjustment and film pressure control.

Processing of product quality

The hydraulic hot press plays a crucial role in ensuring the processing of high-quality products. It allows for precise control over temperature and pressure, leading to consistent and desired results.

Hot pressing process flow chart

Traditional heating methods: steam heating and electric heating

Traditionally, steam heating and electric heating have been the commonly used methods for heating in hot presses. Steam heating is simple but often results in non-uniform temperature distribution. On the other hand, electric heating consumes a large amount of power and leads to high operating costs.

Issues with traditional methods: non-uniform temperature, high power consumption, operating costs

The traditional heating methods used in hot presses have several drawbacks. Steam heating often leads to non-uniform temperature distribution across the board, affecting the quality of the final product. Electric heating, although widely used, consumes a significant amount of power, resulting in high operating costs for businesses.

Introduction of heating oil heating method

To overcome the limitations of traditional heating methods, the heating oil heating method has been introduced. This method offers several benefits, including high heat capacity, uniform temperature distribution, low heat loss, reduced production costs, and the ability to achieve the desired hot pressing effect.

Benefits: high heat capacity, uniform temperature, low heat loss, reduced production cost, desired hot pressing effect

The heating oil heating method in hydraulic hot presses provides several advantages. The high heat capacity of the oil allows for efficient and effective heating. The uniform temperature distribution ensures consistent results throughout the hot pressing process. The low heat loss reduces energy consumption and production costs. Ultimately, this method enables businesses to achieve the desired hot pressing effect while optimizing their operations.

In conclusion, the function of a hydraulic hot press is to offer precise temperature selection, technical control, and processing of high-quality products. By adopting the heating oil heating method, businesses can overcome the issues associated with traditional heating methods and enjoy the benefits of high heat capacity, uniform temperature distribution, and reduced production costs.

Features of Hydraulic Hot Press

Automated and easy-to-operate control panel

The hydraulic hot press is equipped with an automated control panel that is easy to operate. With just one person, the machine can be operated efficiently, saving on labor costs.

control panel

Use of well-known electronic components for stability and longevity

To ensure stability and longevity, the hydraulic hot press incorporates well-known electronic components. These components are known for their reliability and can withstand continuous use over an extended period of time.

Inclusion of hydraulic balance device for stability and quick movement

To enhance stability and enable quick movement, the hydraulic hot press is equipped with a hydraulic balance device. This feature ensures that the machine moves smoothly and efficiently during operation.

Efficient heating system to ensure fast heat conduction to each layer

The hydraulic hot press is equipped with an efficient heating system that facilitates fast heat conduction to each layer. This ensures uniform heating throughout the material being pressed, resulting in consistent and high-quality end products.

Our hot press machine advanced automatic system, automatic pressurization, pressure-holding, and pressure-replenishment so that the plate is subjected to uniform pressure from the beginning to the end.

The heat plate of the machine is made of solid longitudinal drilled steel plate, with good precision and durability of the pressure plate. Its hot pressing system heats up quickly. The pressure adjustment is also quite easy. And the heating system and heat conduction system are designed in sections, with low heat consumption and uniform heat conduction.

The machine has Haas' original full-automatic pressurization and replenishment function, no need for manual operation, and the pressure is controllable. The temperature control is imported from Japan, it ensures the accurate temperature of the hot press machine and saves electricity.

It is made of original steel to ensure that the equipment will never be deformed by high pressure.

Original steel

Hydraulic core system: heavy-duty hydraulic cylinder and hydraulic valve set are manufactured by the German Rexroth brand. The heavy-duty hydraulic pump station adopts the famous German brand, the cylinder adopts Taiwan heavy-duty hydraulic cylinder, the automatic hydraulic valve block relief valve, and the one-way pressure-keeping valve is made in Italy. The use of German imports of solid oil seals ensures that the service life is extended.

The heat hydraulic press adopts advanced electronic control, which can complete the processing process through the change. It is powered by oil pressure and compressed air, so there should be enough air pressure and air volume. The frame is made up of the whole processing with steel plate, and the whole structure is reasonable, and the two working tables can be used in the cycle.

Adopting four columns and three plate structures, the movable plate is parallel to the table and has high precision.

The heat press adopts pulse heating technology. Its temperature control is precise, and the temperature sampling frequency is 0.1s.

It uses a stroke adjustable cylinder with high accuracy of lower dead point positioning. Its stroke accuracy is optional at 0.01mm.

Single working platform, rotating working platform, left and right moving platform, and other diversified working modes.

Multi-stage temperature rises control.

Real-time temperature curve display.

The moulded board is divided into a standard upper heating zone and a lower cooling zone. The upper heating plate is built with multiple electric heat pipes, which can be heated stably and reliably. The lower cold pressing plate has a snake-like water cooling pipe, which can cool down quickly and forcefully. Electrical heating and water cooling integration of the layout, a wide range of applications.

The hydraulic system has the function of automatic pressure compensation, delay stop and pressure keeping, including at least two pressure sets and two units display, and multiple exhaust actions can be set arbitrarily. The optimized electro – hydraulic drive combination design reduces the energy consumption and efficiency of the product while improving the efficiency.

The electrical control system is distributed in accordance with CE or higher standards. All electrical components are of pure brand. Temperature control, time, and pressure can be set and displayed.

Applications of Hydraulic Hot Press

METAL PROCESSING: Hydraulic hot press is widely used in metal processing industry for manufacturing metal products, parts and tools. For example, it can be used for hot press molding of metal plates, tubes, profiles, casting parts, etc.

Plastic Molding: Hydraulic hot press can be used in plastic molding process, such as hot press molding, hot press molding, etc.. It can heat the plastic material to a molten state and then apply pressure through the hydraulic system to form the desired shape in the mold.

Rubber Processing: In the rubber industry, hydraulic hot presses can be used for molding and processing of rubber products, such as the production of rubber seals, rubber gaskets, rubber hoses and so on.

Wood processing: Hydraulic hot presses can also be used in the wood processing field. It can be used for hot press molding of wood, manufacturing of plywood, and texturing of wood.

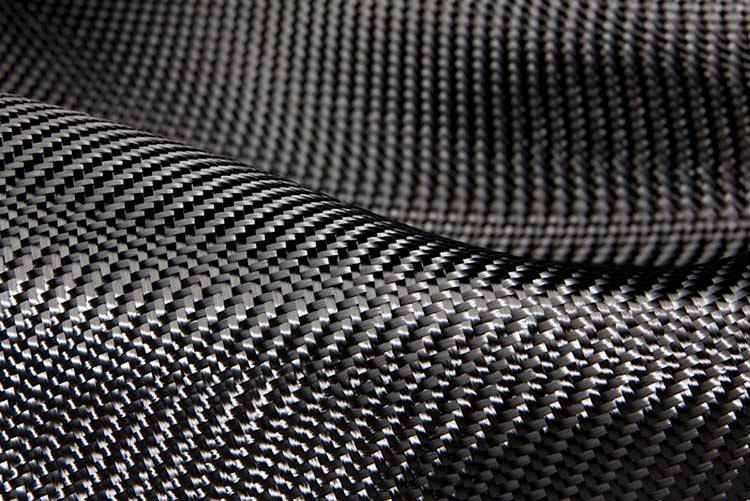

Composite Material Manufacturing: Hydraulic hot presses play an important role in the manufacturing of composite materials. It can be used to laminate different materials together to form high-strength, high-performance composite products, such as carbon fiber composite parts, glass fiber reinforced plastics and so on.

Overall, hydraulic hot presses have a wide range of applications in various industries for processing a variety of materials to improve productivity and product quality.

If you are interested in our products, please visit our company website:https://kindle-tech.com/product-categories/heated-lab-press, where innovation has always been a priority. Our R&D team consists of experienced engineers and scientists who closely follow industry trends and are constantly pushing the boundaries of what is possible. Our laboratory equipment incorporates the latest technology to ensure that you can obtain accurate and repeatable results during your experiments. From high-precision instruments to intelligent control systems, our products will provide you with unlimited possibilities for your experimental work.

Related Products

- Manual Lab Heat Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

- 30T 40T Split Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

Related Articles

- Understanding the Importance and Applications of Laboratory Presses

- Understanding Hydraulic Pellet Press: Working Mechanism and Applications

- Hydraulic Presses vs. Mechanical Presses Which is Right for Your Laboratory

- What is lab hydraulic press

- The Science Behind Hydraulic Presses and Their Applications