Introduction

Table of Contents

Laboratory presses play a vital role in various industries, providing precision and consistency in demanding operations. These versatile machines are used for testing, compacting, and molding materials in sectors such as pharmaceutical, laminating, rubber, and plastic molding. Whether it's for R&D, limited production, or lean manufacturing, laboratory presses offer durability and rigorous demand fulfillment. In industrial research, these presses are essential for high-demand operations and material testing. With programmable controls and a variety of designs to choose from, including countertop and floor standing presses, finding the right laboratory press that meets your requirements is crucial.

The Role of Laboratory Presses in Various Industries

Pharmaceutical, Laminating, Rubber and Plastic Molding Industries

A laboratory press, also known as a laboratory platen press, is a device used to press different types of sample materials, such as rubbers, polymers, and composites. These presses are essential in various industries, including pharmaceutical, laminating, rubber, and plastic molding industries.

Laboratory presses play a crucial role in preparing samples for a wide range of tests conducted in these industries. These tests include elongation tests, Mooney viscosity, tensile strength, and more. In order to ensure accurate and reliable test results, it is important to create consistent and well-made specimens.

One of the key advantages of using a laboratory press is its ability to quickly change settings and switch between different sample types and materials. For example, if you need to prepare PP-samples and then switch to PE-samples, a laboratory press allows for easy and efficient transitions. This is in contrast to production presses or injection molding machines, which can be more time-consuming and cumbersome for such changes.

Laboratory presses also have a small footprint, making them convenient to be housed inside the lab where testing is conducted. Scientists and researchers prefer working with laboratory platen presses due to their precision and ability to provide reliable and consistent results over time.

R&D, Testing, Short Runs, Limited Production, Cell Manufacturing, Lean Manufacturing

Laboratory presses are not limited to specific industries but are used across various sectors for different purposes. They are commonly used for research and development (R&D) work, testing, short production runs, limited production, cell manufacturing, and lean manufacturing.

These presses are equipped with hydraulic systems that can generate up to 1,000 pounds per square inch (psi) of pressure. This pressure can be applied to a variety of materials, including powders, sheet materials, and polymer beads.

The durability and precision of laboratory presses make them highly preferable for scientists and researchers in meeting rigorous demands and achieving accurate results. These presses have a long life in the lab and provide consistent results, making them an integral part of industrial inquiries.

In addition to the aforementioned industries, laboratory presses are also used in other material categories such as ceramics, wood, thermoplastic resins, textiles, laminating, and pharmaceutical applications. They are versatile machines that find applications in educational and research purposes in universities as well.

To summarize, laboratory presses are essential tools in a wide range of industries. They play a crucial role in preparing samples for tests, ensuring accuracy and consistency. With their ability to switch between different sample types and materials, laboratory presses offer convenience and efficiency. Their durability and precision make them highly sought after by scientists and researchers in meeting the demands of research and development, testing, and production.

Advantages of Laboratory Presses

Precision and Rigorous Demand Fulfillment

Laboratory presses are essential tools for preparing samples with reproducible characteristics. They offer uniform temperature distribution over the platen surface and mechanical solidity, ensuring a constant thickness of the sample and consistent closure force. This precision is crucial for meeting the rigorous demands of scientific research and experimentation.

A dedicated laboratory platen press allows researchers to quickly change settings and easily switch between different sample types and materials. This flexibility is highly beneficial, as it saves time and allows for efficient workflow. Unlike production presses or injection molding machines, laboratory presses offer convenience and versatility.

Furthermore, laboratory presses have a small footprint, making them ideal for housing inside the lab where testing is conducted. This proximity to the testing area eliminates the need for transporting samples, reducing the risk of contamination and ensuring accurate results.

Durability and Consistency

Laboratory presses are designed to withstand the demands of continuous use in research and development environments. Their durability ensures long life in the lab, providing consistent and reliable results over the years. Scientists and researchers prefer working with laboratory platen presses because of their ability to deliver precise and consistent results consistently.

Laboratory platen presses are widely used in various industries and material categories for preparing samples for R&D and quality tests. Industries such as pharmaceuticals, laminating, rubber, plastic molding, and more benefit from the use of laboratory presses.

In addition to their precision and durability, laboratory presses offer ease of use and maintenance. They are designed with programmable controls, allowing for accurate and consistent pressing according to specific requirements. The presses are also easy to clean and maintain, with simple designs that are easy to disassemble and reassemble.

Overall, laboratory presses offer a range of advantages, including precision, ease of use, durability, and versatility. They are essential tools for scientists and researchers in various industries, providing the reliable and consistent results needed for successful research and development.

Importance of Laboratory Presses in Industrial Research

High Demand Operations

A dedicated laboratory platen press is essential in industrial research due to its ability to handle high-demand operations. These presses allow researchers to quickly change settings and switch between different sample types and materials with ease. Unlike production presses or injection molding machines, laboratory presses offer convenience and efficiency in sample preparation. They have a small footprint, making them suitable for placement inside the lab where testing is conducted.

Scientists and researchers prefer working with laboratory platen presses because of their precision and ability to provide reliable and consistent results over the years. These presses play a crucial role in various industries and material categories, enabling R&D and quality tests. However, manual hydraulic presses can be laborious for labs that require recurrent production of pressed samples. In such cases, automatic presses are more convenient and enable a faster pace of work.

If you are looking for the right hydraulic press for your laboratory application, it is crucial to choose the equipment that ensures accurate results. KinTek offers a range of hydraulic presses suitable for a variety of applications. With their help, you can find the ideal press that meets your needs and delivers accurate and repeatable results.

Essential for Testing and Compacting Materials

Laboratory hydraulic presses are indispensable for testing and compacting various materials in industrial research. These heavy-duty machines are particularly important for materials such as rubber, plastic, and laminate materials. They allow researchers to analyze material performance during manufacturing processes by creating test substances. Hydraulic presses assess blocking resistance by testing the print material's ability to adhere to itself under pressure.

Moreover, laboratory hydraulic presses are used in power compaction to create a wide range of composite materials. The process is similar to sample preparation for spectroscopy, but it results in lightweight yet sturdy composite materials used in studying ferromagnetics and metal matrix composites.

Hydraulic presses also find application in prototyping microfluidic devices, which are in high demand for handling tiny liquid amounts. By creating precise prototypes, hydraulic presses ensure the correct functionality of the final devices.

Laboratory presses come in various types and are designed to apply pressure to compress or compact samples. Equipped with a hydraulic system capable of generating up to 1,000 pounds per square inch (psi) of pressure, these presses can handle powders, sheet materials, and polymer beads. They find uses in pharmaceutical, laminating, rubber and plastic molding industries, as well as in R&D work, testing, short runs, limited production, cell manufacturing, and lean manufacturing.

The undeniable precision and durability of laboratory presses make them a preferred choice for scientists and researchers. These presses deliver long-lasting and consistent results, ensuring the success of industrial inquiries and research operations.

If you are in need of a laboratory press for your research or testing needs, consider KinTek's range of hydraulic presses. They offer a variety of sizes and configurations to suit different applications, ensuring accurate and repeatable results.

Design and Manufacturing of Laboratory Presses

Types of Hydraulic Press Explained

Laboratory presses are available in a variety of sizes and configurations. Which one you need will usually be determined by the intended application – as well as how well it fits with your lab’s workflow and user requirements.

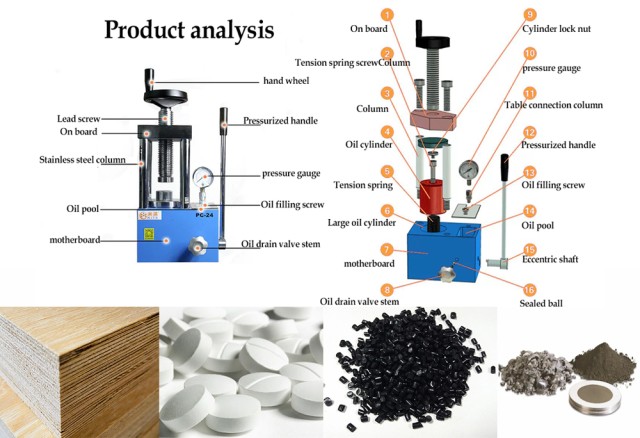

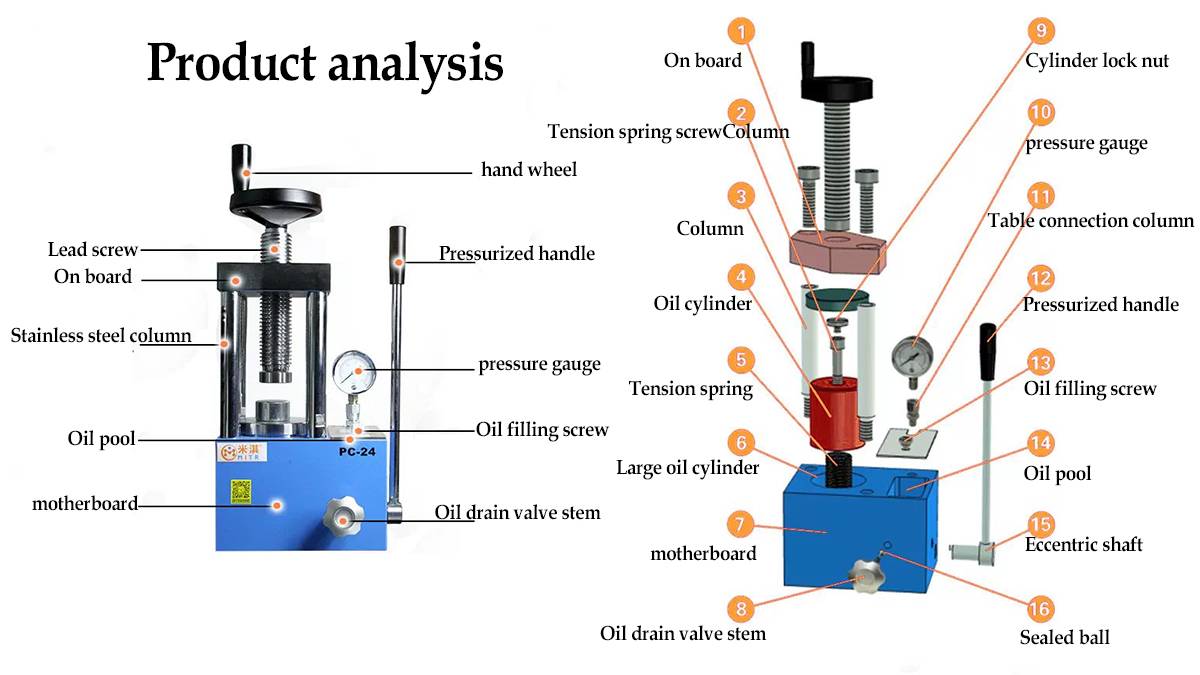

Manual Hydraulic Press

A manual hydraulic press uses a hand-operated lever to apply load to a sample. It consists of a mechanical lever that controls a piston which moves in a cylinder containing hydraulic oil, exerting pressure on a die or head containing the desired material. By turning the lever back and forth, pressure from the cylinder can be increased or decreased until an optimal amount of force is achieved for a given task.

Even though the LAB range is standard, we are dedicated to customizing our products on client request.

Hydraulic Laboratory Press for Sugar Cane Sucrose Determination

Our teams have designed and provided many laboratory presses for the sugar cane industry worldwide. These hydraulic presses, with a capacity from 125kN up to 700kN, are dedicated to sugar cane sucrose determination and analysis.

Custom Engineered Lab Presses & Small Production Systems

A new generation of automated machines has emerged on the market of composites. This type of machine allows composite parts manufacturers to be ready for high-rate production of composite parts. However, before launching the production, it is necessary to check and validate the process on laboratory machines. To do so, KinTek is able to design and deliver custom engineered laboratory presses and small production systems.

A benchtop press should be considered for laboratories with space restrictions. They provide the same customization options and high quality as alternative presses that are larger while having a smaller footprint.

The benchtop press range from KINTEK has both automatic and hand-operated models, with a variety of optional features for greater customization to the task at hand. The standard model on the manual side is available in 12, 25, and 35-ton capacities. It can be employed for tasks such as pelletizing, fluid extraction, pressure forming, destructive testing, and much more.

The design and manufacture of these presses typically include programmable controls, allowing users to press products more accurately, consistently, and according to specific requirements. Though many lab presses are fit for the countertop, there are also many floor-standing presses available. Either way, it is not uncommon to find laboratory presses designed with two-columns and four-columns and that press either manually or automatically.

With such a vast selection of laboratory presses out in the market, it could become confusing as to which one is best suited for a particular job. An important factor to remember when choosing this particular kind of hydraulic press is how much force is needed for a specific sample? It is also necessary to consider how much space is provided in the lab, how much energy and strength are required to pump the press, and whether or not the press will have to move.

Pharmaceutical, laminating, rubber, and plastic molding industries are among those that benefit from laboratory presses. Laboratory presses are also common among R&D work, testing, short runs, limited production, cell manufacturing, and lean manufacturing.

The main reason that scientists and researchers prefer these types of presses is because of their undeniable precision and their ability to meet rigorous demands. The durability of lab presses also ensures long life in the lab, providing long-lasting and consistent results.

Operations within research come with high demands, which is exactly why laboratory presses are an integral part of industrial inquiries. For testing and compacting materials such as rubber, plastic, and laminate materials, these heavy-duty machines are extremely important.

KinTek provides hand-actuated laboratory presses, which combine simplicity with excellence. Our presses, with a capacity from 20 to 200 kN and cylinders with return spring, are operator-friendly and require low maintenance, thanks to their trusted design. The standard press can heat up to 300 °C, for a 100 mm stroke, but we can adapt the stroke up to 200 mm, according to your needs.

Standard Laboratory Press Range (Lab Press)

To equip laboratories or really small production units, we have launched a varied range of standard laboratory presses. This new range allows the customer to choose the required performance while limiting the required investment. The LAB, LAB P (Programmable), and Lab PA (Programmable + data Acquisition) standard presses are equipped with high temperature heating and cooling platens (up to 450 °C) and apply up to a 1,000 kN effort. These machines can perform the following processes:

- Mechanical structure with 4 columns (with 60 mm diameter) and sliding platen driven by self-lubricating bushings

- Hydraulic system with 25 tons closure force

- 250x250 mm chrome plated steel platens with 40 mm thickness

- Specifically designed flat heating elements to ensure uniform temperature distribution over the platen surface

- Closed molding area for easy fume aspiration

- Protection doors with safety lock

- CE Labelling

Automatic Press Control: The PLC controller for the press is provided with a user-friendly Touch Screen Display and permits the free definition of the molding cycle by setting the displacements of the moving platen of the press, the thermal cycle (different temperatures of the platens and thermal gradients can be set within a molding cycle), and the pressure cycle (with the force control option installed). Three molding cycles can be stored. Each cycle includes 24 molding steps (including displacements, temperature setups, and pressure setups).

Cooling System: The cooling of the press platens during the molding cycle is necessary for the molding of thermoplastic materials because the material must be cooled to the solidification temperature before opening the mold.

Different Types of Hydraulic Presses

At KINTEK, we provide two types of powered (electric) hydraulic presses and two types of manual hydraulic presses. The manual presses available can be either full-size or handheld. The electric presses come either with or without LED touchscreens and custom programmable loads.

Choosing the Right Laboratory Press

Considerations: Force Required, Lab Space, Energy and Strength Required

When it comes to laboratory applications, selecting the right hydraulic press is crucial for obtaining accurate and reliable results. With a wide range of options available, KinTek offers hydraulic presses that cater to various needs and requirements.

Force Required

One of the key factors to consider when choosing a laboratory press is the amount of force required for your specific sample. Different applications may demand varying levels of clamping force, dwelling time, and temperature. It is essential to select a press that can generate the necessary force to achieve optimal results.

Lab Space

The available space in your laboratory is another important consideration. KinTek provides both countertop and floor-standing hydraulic presses, allowing you to choose the option that best fits your lab's dimensions. Whether you have limited space or ample room, there is a suitable press available.

Energy and Strength Required

The energy and strength required to operate the hydraulic press should also be taken into account. Manual hydraulic presses may be suitable for occasional use or smaller samples. However, if your lab staff needs to produce pressed samples regularly, an automatic press would be more convenient and efficient, enabling a quicker pace of work.

Mobility of the Press

Another factor to consider is whether or not the press needs to be mobile. If you anticipate the need to move the press within your lab or between different locations, it's important to select a press that offers easy mobility.

KinTek's Extensive Experience

With their extensive experience in the field, KinTek can assist you in selecting the right laboratory press for your application. Their sales team and engineers can use their expertise to provide you with a standard press or even customize one to meet your unique needs.

Why Choosing the Right Hydraulic Press Matters

Every laboratory application has specific requirements that need to be met in order to obtain accurate and successful results. Factors such as clamping force, dwelling time, and temperature play a crucial role in the creation of samples. Choosing the right hydraulic press ensures that these requirements are met, leading to the best possible outcome.

Do I Really Need a Hydraulic Press?

If your lab work involves briquetting for XRF or KBr pellets, a hydraulic press is essential. There is no alternative that can provide the same level of accuracy and precision. However, for other applications, such as smaller samples or occasional use, a hand press may be sufficient to meet your needs.

In conclusion, selecting the right laboratory press is vital for achieving accurate and repeatable results. Considerations such as the force required, lab space, energy and strength required, and mobility of the press are all important factors to take into account. With KinTek's extensive experience in the field, they can guide you in choosing the most suitable press for your specific application.

Conclusion

In conclusion, laboratory presses play a vital role in various industries, including pharmaceutical, laminating, rubber and plastic molding industries. They are also essential for R&D, testing, short runs, limited production, cell manufacturing, and lean manufacturing. The advantages of laboratory presses lie in their precision, durability, and consistency, making them suitable for fulfilling rigorous demands. These presses are of great importance in industrial research, especially in high-demand operations and material testing and compaction. When choosing a laboratory press, factors such as force required, lab space, energy and strength needed, and mobility should be considered. Overall, laboratory presses are indispensable tools in many industries, enabling efficient and precise operations.

If you are interested in our products, please visit our company website:https://kindle-tech.com/product-categories/heated-lab-press, where innovation has always been a priority. Our R&D team consists of experienced engineers and scientists who closely follow industry trends and are constantly pushing the boundaries of what is possible. Our laboratory equipment incorporates the latest technology to ensure that you can obtain accurate and repeatable results during your experiments. From high-precision instruments to intelligent control systems, our products will provide you with unlimited possibilities for your experimental work.

Related Products

- Manual Lab Heat Press

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Laboratory Manual Hydraulic Pellet Press for Lab Use

Related Articles

- Comprehensive Guide on Pellet Press Dies and Their Applications

- An Insight into Hydraulic Presses: Versatility, Efficiency, and Industrial Applications

- Understanding Hydraulic Pellet Press: Working Mechanism and Applications

- Applications and Importance of Hydraulic Press in Laboratories

- Hydraulic Presses vs. Mechanical Presses Which is Right for Your Laboratory