Molds & Accessories

Lab Infrared Press Mold

Item Number : PMID

Price varies based on specs and customizations

- Material

- Carbide YT15

- Sample size

- φ13 mm

- Cavity depth

- 20 mm

- External dimensions

- φ43×78 mm

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Applications

After the mold is pressed, the sample needs to be released from the mold, placed on the magnetic sample holder for testing, and then placed in the sample chamber of the infrared spectrometer for testing.

The mold is widely used in battery, superconductor, cement, ceramics, catalysis, silicate, powder metallurgy, sea mud analysis, biochemical analysis and new material sample preparation research and development. In addition, the product can also be used with calcium iron, infrared, X-ray fluorescence and other testing instruments.

Special sizes press molds can be customized according to customer requirements.

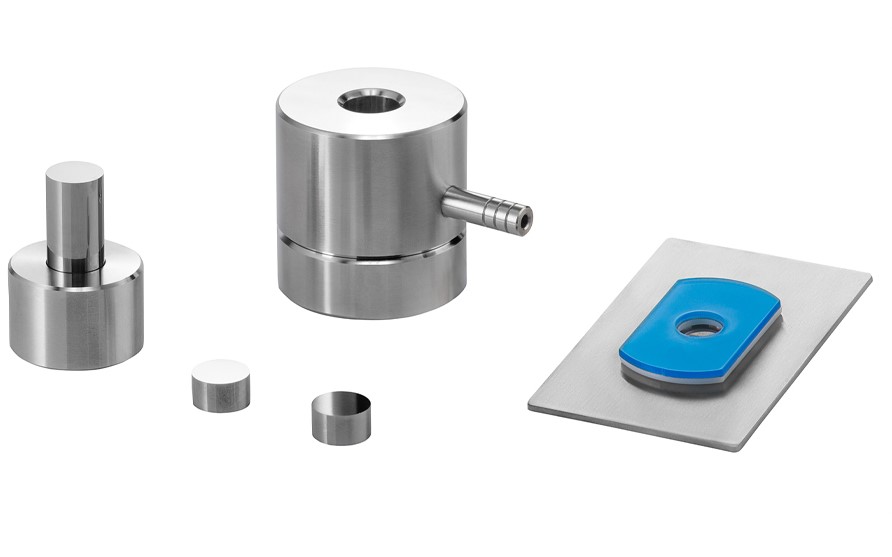

Detail & Parts

Technical specifications

| Instrument model | PMID | |

| Sample shape |  |

|

| Die material | Tungsten carbide | |

| Indenter hardness | HRC68-HRC85 | |

| Sample size | Φ13 mm(M) | |

| Cavity depth | 20mm(N) | |

| Dimensions | Φ43*78mm(L*H) | |

| Weight | 0.76Kg | |

| Diagram of hydraulic powder press size |  |

|

Operation steps

After forming, take out the sample from the infrared release die, put it on the magnetic sample stand, and then put it in the sample warehouse of infrared spectrometer for testing. Die size: Diameter 13mm; Die sheet thickness: 0.5~1mm.

Step 1: Assemble the die according to the operation diagram and install the sample in the cavity.

Step 2: Put the die in the center of the hydraulic press and pressurize to required pressure.

Step 3: Assemble the die according to the release diagram , eject the sample out of the die bushing with the screw rod.

Step 4: Take out the die from the hydraulic press , and remove the sample gently.

Precautions for mold maintenance

To ensure accurate test results, clean the mold surface with dust-free paper before each use to avoid the anti-rust oil from affecting the sample. Avoid exceeding the maximum pressure when applying pressure. Clean the mold and samples after use to prevent corrosion. Apply anti-rust oil and store the mold in a dry environment if not used for a long time to prevent damage.

Step 1: Placing the Mold.

To begin, place the mold in the center of the tablet press. It is important to note that the maximum pressure of the mold cannot be exceeded when pressurized. This will prevent any damage to the mold and ensure accurate test results.

Step 2: Cleaning the Mold.

After each use, it is essential to clean the mold to prevent any contamination of the sample. Using dust-free paper, wipe the surface of the mold clean. If there are sample residues on the surface that cannot be removed, please do not use chemical reagents to clean and soak. This could potentially damage the mold and impact the accuracy of the test results.

Step 3: Applying Anti-Rust Oil.

If the mold is not used for an extended period, it is recommended to apply anti-rust oil on the surface of the mold to prevent rusting. This step will help prolong the life of the mold and ensure that it remains in good condition for future use.

Step 4: Storing the Mold.

Lastly, if the mold is not used for a long time, it needs to be stored in a dry environment. This will prevent any moisture from accumulating on the mold and causing damage.

Full range of lab press types

Click to view our full range of lab press products.

Any question? Our experts have helped many laboratories choose their lab press, contact us now!

Full range of types of laboratory press molds

We have a full range of molds for you to choose from, and the molds fit the body perfectly.

If you need molds with special shapes, we can also customize them for you.

Warnings

Operator safety is the top important issue! Please operate the equipment with cautions. Working with inflammable& explosive or toxic gases is very dangerous, operators must take all necessary precautions before starting the equipment. Working with positive pressure inside the reactors or chambers is dangerous, operator must fellow the safety procedures strictly. Extra caution must also be taken when operating with air-reactive materials, especially under vacuum. A leak can draw air into the apparatus and cause a violent reaction to occur.

Designed for You

KinTek provide deep custom made service and equipment to worldwide customers, our specialized teamwork and rich experienced engineers are capable to undertake the custom tailoring hardware and software equipment requirements, and help our customer to build up the exclusive and personalized equipment and solution!

Would you please drop your ideas to us, our engineers are ready for you now!

Trusted by Industry Leaders

FAQ

What Is A Press Mold?

What Is Press Mould In Ceramics?

How Are Pellet Molds Used?

What Types Of Materials Can Be Pelletized Using Pellet Molds?

How Can One Select The Appropriate Pellet Mold For Their Specific Application?

4.8 / 5

The lab infrared press mold is a game-changer for our research. It's incredibly precise and durable, giving us consistent results every time.

4.9 / 5

The customer service at KinTek Solution is top-notch. They were very helpful and responsive when I had questions about the lab press.

4.7 / 5

KinTek's lab infrared press mold is a great value for the price. It's a high-quality product that has saved us a lot of time and money.

4.8 / 5

The lab infrared press mold is easy to use and maintain. It's a great addition to our lab, and we're very happy with it.

5.0 / 5

The delivery of the lab infrared press mold was incredibly fast. We received it within a few days of ordering it.

4.6 / 5

The lab infrared press mold is a great investment for any lab. It's durable and reliable, and it produces high-quality results.

4.9 / 5

KinTek's lab infrared press mold is a must-have for any lab that needs to press samples. It's a high-quality product that produces excellent results.

4.7 / 5

The lab infrared press mold from KinTek Solution is a great addition to our lab. It's easy to use and produces great results.

5.0 / 5

The lab infrared press mold is a great tool for preparing samples for analysis. It's easy to use and produces high-quality results.

4.8 / 5

The lab infrared press mold is a valuable addition to our lab. It's a versatile tool that can be used for a variety of applications.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

No Demolding Lab Infrared Press Mold for Laboratory Applications

Effortlessly test your samples with no demolding required using our lab infrared press mold. Enjoy high transmittance and customizable sizes for your convenience.

Infrared Heating Quantitative Flat Plate Press Mold

Discover advanced infrared heating solutions with high-density insulation and precise PID control for uniform thermal performance in various applications.

Round Bidirectional Press Mold for Lab

The round bidirectional press mold is a specialized tool used in high-pressure molding processes, particularly for creating intricate shapes from metal powders.

Special Heat Press Mold for Lab Use

Square, round and flat plate forming dies for hot presses.

Ball Press Mold for Lab

Explore versatile Hydraulic Hot Press molds for precise compression molding. Ideal for creating various shapes and sizes with uniform stability.

Assemble Lab Cylindrical Press Mold

Get reliable and precise molding with Assemble Lab Cylindrical Press Mold. Perfect for ultra-fine powder or delicate samples, widely used in material research and development.

Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

Controlled environment lab press machine for glove box. Specialized equipment for material pressing and shaping with high precision digital pressure gauge.

Multi-Punch Rotary Tablet Press Mold Ring for Rotating Oval and Square Molds

The multi-punch rotary tablet press mold stands as a pivotal component in pharmaceutical and manufacturing industries, revolutionizing the process of tablet production. This intricate mold system comprises multiple punches and dies arranged in a circular fashion, facilitating rapid and efficient tablet formation.

Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

Efficiently prepare your samples with our Automatic Heated Lab Press. With a pressure range up to 50T and precise control, it's perfect for various industries.

Infrared High Resistance Single Crystal Silicon Lens

Silicon (Si) is widely regarded as one of the most durable mineral and optical materials for applications in the near-infrared (NIR) range, approximately 1 μm to 6 μm.

High Energy Planetary Ball Mill Milling Machine for Laboratory

The biggest feature is that the high energy planetary ball mill can not only perform fast and effective grinding, but also has good crushing ability

High Energy Vibratory Ball Mill for Lab Use

The high-energy vibrating ball mill is a high-energy oscillating and impacting multifunctional laboratory ball mill. The table-top type is easy to operate, small in size, comfortable and safe.

kbr pellet press 2t

Introducing the KINTEK KBR Press - a handheld laboratory hydraulic press designed for entry-level users.

Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

The Manual Heat Press is a versatile piece of equipment suitable for a variety of applications, operated by a manual hydraulic system that applies controlled pressure and heat to the material placed on the piston.

Related Articles

Infrared Press Mold Techniques for Non-Demolding Applications

Explore advanced infrared press mold techniques without demolding. Learn about the benefits, applications, and best practices for non-demolding lab processes.

Pressing Powder Samples and Molding Polymer Films: A Comprehensive Guide

Pressing powder samples is done to create a solid material that remains intact even after the load is removed. This process involves pushing the powder grains closer together, closing the gaps between them and forcing them to flow and rearrange themselves into a more compact arrangement. As the available volume reduces, the flow of particles stops, and they undergo plastic and elastic deformations that result in bonding between the grains.

How to Use FTIR Pellet Press to Prepare Samples for Analysis

Fourier Transform Infrared (FTIR) spectroscopy is a powerful analytical technique used to identify and quantify chemical compounds in a wide range of samples. FTIR analysis requires the sample to be in the form of a pellet, which is prepared by compressing the sample with a suitable matrix material.

How FTIR Pellet Press Works in Sample Preparation for Spectroscopy Analysis

FTIR (Fourier Transform Infrared) spectroscopy is a powerful analytical technique for identifying and characterizing chemical compounds based on their infrared absorption spectra.

CIP vs. Metal Mold Pressing What's the Difference

CIP and Metal Mold Pressing are used to create high-density components, but they differ in terms of the level of complexity required and the final outcome. Understanding these differences can help manufacturers determine which method is best suited for their needs.

FTIR Pellet Press The Game-Changer in Spectroscopy Analysis

Fourier Transform Infrared Spectroscopy (FTIR) is a widely used analytical technique in the field of chemistry and materials science. It is a non-destructive method that allows the identification and quantification of chemical compounds in a sample.

Techniques for Sample Preparation in X-Ray Fluorescence Analysis: Pressed and Loose Powder Methods

X-ray fluorescence (XRF) analysis is a common technique used for analyzing powders in various industries. When it comes to preparing powder samples for XRF analysis, there are two main methods: pressed powder method and loose powder method.The pressed powder method involves compressing the sample into a pellet or disk, while the loose powder method involves simply placing the sample into a cup or container. Each method has its advantages and disadvantages, and the choice of method depends on the specific requirements of the analysis.

A Guide To PREPARE SAMPLES FOR XRF ANALYSIS

There are many ways to prepare samples for XRF analysis. The choice of method will also affect the time it takes to get results and the cost of the analysis.

Guide for Xrf Pellet Press

An XRF tablet press is a machine used to prepare samples for X-ray fluorescence (XRF) analysis by pressing them into a uniform tablet or pellet form.

Operating of Automatic Lab xrf Pellet Press

How to use the Automatic Lab xrf Pellet Press, including steel ring, plastic ring, boric acid mold

An In-Depth Guide on Laboratory Presses and KBr Pellets Production

In the world of scientific research and analysis, laboratory presses and KBr pellet production play a crucial role. These tools are essential in the preparation of samples for various analytical techniques, such as infrared spectroscopy and XRF spectroscopy.

Operating steps and precautions for electric isostatic press

Relevant introduction to the operating steps and precautions of the electric isostatic press.