Introduction to FTIR Spectroscopy Analysis

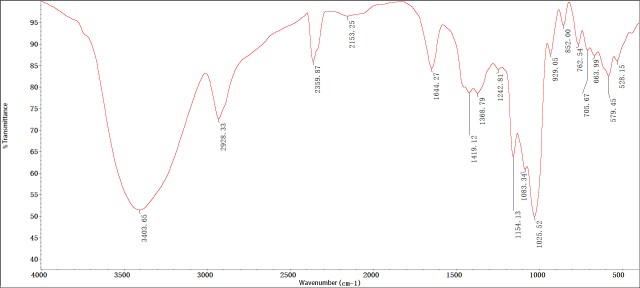

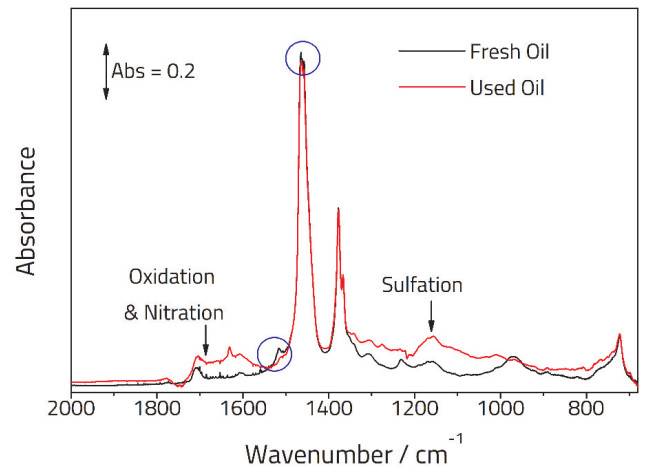

FTIR (Fourier Transform Infrared) spectroscopy is a powerful analytical technique for identifying and characterizing chemical compounds based on their infrared absorption spectra. FTIR analysis provides a unique "fingerprint" of a sample, which can be used to identify unknown materials or to monitor changes in chemical composition. This non-destructive technique has applications in a wide range of fields, including chemistry, materials science, pharmaceuticals, and environmental science. Proper sample preparation is essential for accurate FTIR analysis, as the quality of the sample can affect the accuracy and reproducibility of the results.

Table of Contents

Importance of Sample Preparation in FTIR

FTIR spectroscopy is a powerful analytical technique that can be used to identify and quantify chemical compounds in a sample. However, the accuracy and reliability of FTIR analysis depend on the quality of sample preparation. Here are some important aspects of sample preparation that highlight its importance in FTIR analysis:

Sample Homogeneity

The FTIR pellet press is a laboratory equipment used to prepare highly uniform and homogeneous pellets of solid samples for FTIR spectroscopy analysis. The process involves crushing the sample into a fine powder and mixing it with a binding agent such as potassium bromide (KBr) to form a pellet. The pellet is then placed in the FTIR spectrometer for analysis. The importance of sample preparation using FTIR pellet press lies in the fact that it ensures that the sample is uniformly distributed in the pellet, which reduces the effects of inhomogeneity and enables accurate and reproducible analysis.

Reduction of Interference

The use of KBr as a binding agent ensures that the infrared spectrum of the sample is not affected by interfering absorption bands from the binder. This is important because the presence of interfering absorption bands can make it difficult to identify and quantify the components of the sample.

Transparency to IR Radiations

The sample should be transparent to IR radiations so it allows the radiations to pass through them. Salts like KBr, NaCl, AgCl are used for mixing of the sample to obtain the accurate IR spectrum of a sample with sharp peaks, good intensity, and high resolution.

Correct Sample Amount

The amount of sample used for analysis is also important. FTIR is a very sensitive technique, so you only need a few mg of your sample, and the vast majority of your pellet is KBr (or another IR-transparent material). The typical ratio of KBr to sample is 100:1.

Pellet Thickness

Pellets for FTIR are typically required to be within 3 mm up to 13 mm, the exact diameter will depend on the manufacturer of your FTIR equipment. The goal is to create a thin, transparent pellet that contains the sample you are interested to characterize held in an IR transparent medium (typically KBr), thus these are also known as KBr Pellets.

In conclusion, sample preparation using FTIR pellet press is crucial for obtaining reliable and accurate results in FTIR spectroscopy analysis. Proper sample preparation allows for the reduction of interference and ensures sample homogeneity and correct sample amount. Ultimately, the quality of sample preparation will impact the accuracy and reliability of FTIR analysis.

How FTIR Pellet Press Works

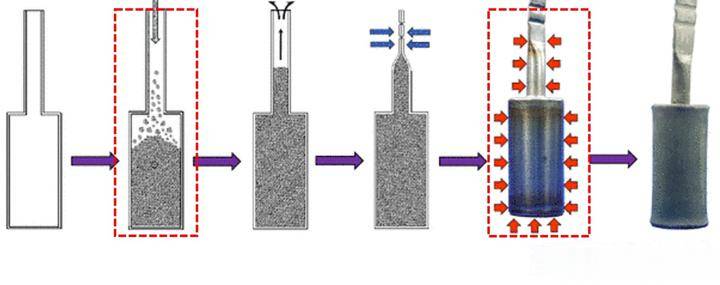

The process of making the FTIR pellet involves placing a small amount of the sample material into the die cavity of the press. Here's how FTIR Pellet Press works in sample preparation for spectroscopy analysis:

Mixing the sample with potassium bromide (KBr)

To prepare the sample for analysis, it is first mixed with potassium bromide (KBr). The sample material is typically a solid or semi-solid material, but can also be a liquid that has been dried into a solid form. KBr is transparent to infrared light, making it a practical method of getting the right amount of sample in the system.

Grinding the mixture

The mixture of KBr and the sample is then ground to a fine powder using a pestle and mortar. The powder should be as fine as possible but also with consistent particle size to provide an optimal distribution and evenness of any x-ray fluorescence sample, which offers better accuracy, repeatability, and consistency of results.

Placing the mixture in the pellet die

The mixture is then put inside a durable container called a ‘pellet die’. There are two types of dies, namely flat disc and cylinder types. The type to be used depends on the characteristic of the powder sample. The die cavity is where the sample mixture is placed before pressing.

Applying pressure

A hydraulic press is used to apply pressure to the sample, which compresses it into a thin, uniform pellet. The FTIR Pellet Press is an important tool in the field of spectroscopy, as it enables researchers to analyze the chemical composition of a wide range of materials, including polymers, pharmaceuticals, foods, and environmental samples.

Removing the pellet

The pellet is then removed from the die cavity and placed into the FTIR Spectrometer for analysis. The hydraulic press makes producing these discs quick, easy, and repeatable, for reliable and efficient test conditions.

Benefits of using FTIR Pellet Press

The FTIR Pellet Press is a reliable and efficient method for preparing samples for spectroscopy analysis, allowing researchers to obtain accurate and precise results. It is also a time-saving method compared to other sample preparation techniques such as hand press. The use of FTIR Pellet Press in sample preparation is a crucial step in the analysis of various materials using FTIR spectroscopy, ensuring that researchers obtain reliable and accurate results.

In conclusion, FTIR Pellet Press is a laboratory equipment that is used to prepare samples for infrared spectroscopy analysis. It works by compressing a small amount of sample material into a thin pellet, which is then analyzed using Fourier Transform Infrared (FTIR) Spectroscopy. The use of FTIR Pellet Press in sample preparation is a crucial step in the analysis of various materials using FTIR spectroscopy, ensuring that researchers obtain reliable and accurate results.

Potassium Bromide (KBr) and Its Role

Introduction

In order to analyze a sample using FTIR spectroscopy, the sample must be prepared in a specific way. This is where the FTIR pellet press comes in. A specialized piece of laboratory equipment, the press is used to prepare solid samples for spectroscopy analysis. One of the most commonly used materials for making these pellets is potassium bromide (KBr).

KBr Properties

KBr is used because it is transparent in the infrared region of the spectrum and does not interfere with the analysis of the sample. Additionally, KBr is easy to handle and can be ground into a fine powder, making it ideal for use in the pellet press. KBr is also hygroscopic, which means it can absorb moisture from the air. Hence, it must be well-purified before use.

KBr's Role in Sample Preparation

The role of KBr in the sample preparation process is to act as a binder, holding the sample particles together in a solid form. When a mixed sample and KBr powder are compressed inside a die using a hydraulic press, the uniform force produces a solid pellet that is mostly transparent to infrared light. The pellet contains a dilute quantity of sample, which is within the detection range of an FTIR instrument.

Sample/KBr Ratio

The concentration of the sample in KBr should be in the range of 0.2 to 1 percent. The pellet is much thicker than a liquid film, hence a lower concentration in the sample is required (Beer's Law). Too high a concentration usually causes difficulties obtaining clear pellets. The IR beam is absorbed completely, or scattered from the sample, which results in very noisy spectra.

Sample Preparation

Although a homogeneous mixture will give the best results, excessive grinding of the potassium bromide is not required. The finely powdered potassium bromide will absorb more humidity (it is hygroscopic) from the air and therefore lead to an increased background in certain ranges. The sample must be very finely ground as in the Nujol mulling technique to reduce scattering losses and absorption band distortions.

KBr Pellet Method

This method is used to prepare a KBr pellet. Approximately 0.1 to 1.0 % sample is well mixed into 200 to 250 mg fine alkali halide (KBr) powder and then finely pulverized and put into a pellet-forming die. A force of approximately 8 tons is applied under a vacuum of several mm Hg for several minutes to form transparent pellets. Degassing is performed to eliminate air and moisture from the KBr powder. Inadequate vacuum may result in easily broken pellets that scatter light. Before forming the KBr powder into pellets, pulverize it to 200 mesh max. and then dry at approximately 110 °C for two to three hours.

Conclusion

In conclusion, potassium bromide (KBr) plays a critical role in the preparation of solid samples for FTIR spectroscopy analysis. KBr is used as a binder to hold the sample particles together in a solid form. It is transparent in the infrared region of the spectrum and does not interfere with the analysis of the sample. When KBr and the sample are compressed inside the die, the uniform force produces a solid pellet that is mostly transparent to infrared light. By using a FTIR pellet press and KBr, scientists and researchers can obtain high-quality spectroscopic data that can be used to study the molecular structure and properties of a wide range of materials, including polymers, pharmaceuticals, and biomolecules.

Using the Hydraulic Press to Compress the Sample

To prepare a sample for FTIR analysis, it needs to be in the form of a solid pellet. This is where the FTIR Pellet Press comes into play. The Pellet Press uses a hydraulic press mechanism to compress the sample into a pellet. Here's how it works:

Step 1: Mixing the Sample with a Binding Agent

Before the sample can be compressed, it needs to be mixed with a binding agent such as KBr. The mixing ratio is typically 1 part sample to 100 parts KBr. The sample and KBr are then well mixed to ensure uniform distribution.

Step 2: Placing the Sample into a Die

Once the sample is mixed with KBr, it is placed into a pellet die. The die is typically made of steel and comes in different sizes and shapes depending on the application.

Step 3: Applying Pressure with a Hydraulic Press

The die containing the sample and KBr mixture is then placed under the hydraulic press. The press mechanism applies pressure to the die, compressing the sample and KBr mixture into a pellet. The hydraulic press allows for precise control over the pressure applied, ensuring reliable and repeatable results.

Step 4: Obtaining a Solid Pellet

The resulting pellet is highly uniform, ensuring consistent results during spectroscopy analysis. The uniform force of the press produces a solid pellet that is mostly transparent to the infrared light but contains a dilute quantity of sample which is within the detection range of the FTIR instrument.

Step 5: Testing the Pellet

After obtaining the pellet, it is tested to ensure that it meets the required specifications. The pellet must be transparent and uniform in order to provide accurate and reliable results during spectroscopy analysis.

In conclusion, the hydraulic press mechanism of the FTIR Pellet Press plays a crucial role in preparing samples for spectroscopy analysis. By following the above steps, the sample can be compressed into a uniform pellet that provides reliable and repeatable results during FTIR analysis. The FTIR Pellet Press is an essential tool for any laboratory involved in FTIR analysis as it provides accurate and reliable results.

Standardizing Pressure Load with a Pressure Gauge

Before analyzing a sample using FTIR spectroscopy, it needs to be prepared in a specific form that will provide consistent and reproducible results. One of the most popular ways to prepare a sample for FTIR analysis is by making a pellet using a FTIR pellet press. This technique involves compressing a small amount of the sample into a thin, flat disc that can be easily analyzed by the FTIR instrument.

To ensure that the sample pellet is properly formed, it is important to standardize the pressure load applied during the pressing process. This is achieved by using a pressure gauge, which measures the amount of force that is applied to the sample. The pressure gauge can be adjusted to achieve the desired level of pressure, which will ensure that the sample pellet is consistent in size and shape.

A standard pressure range for FTIR pellet pressing is between 10 and 20 tons. This range is ideal for most samples, including organic and inorganic compounds. However, some samples require a higher pressure load to achieve the desired results.

Using a pressure gauge is essential for achieving accurate and reproducible results. Without it, the pressure load applied to the sample may vary from sample to sample, leading to inconsistent results. A pressure gauge ensures that the pressure load is standardized, which is essential for achieving accurate and reproducible results.

It is important to note that the pressure gauge should be calibrated regularly to ensure accurate measurements. Calibration should be performed by a qualified technician using a calibration standard.

In addition to using a pressure gauge, it is also important to use a consistent amount of sample for each pellet. This ensures that the pellet size and shape are consistent from sample to sample.

Overall, standardizing pressure load with a pressure gauge is a critical step in sample preparation for FTIR analysis. It ensures that the sample pellet is consistent in size and shape, which is essential for achieving accurate and reproducible results.

Conclusion on the Importance of Sample Preparation

In conclusion, sample preparation is a critical aspect of FTIR spectroscopy analysis that requires careful attention. The quality of the sample preparation can significantly affect the accuracy and reliability of the results obtained from the analysis. The use of the FTIR pellet press for sample preparation provides a reliable and effective method for producing high-quality samples. Furthermore, the use of accessories such as the pressure gauge helps ensure that the correct pressure load is applied during sample preparation, which is essential for obtaining accurate and consistent results. Overall, proper sample preparation is crucial for achieving reliable and meaningful results in FTIR spectroscopy analysis.

Related Products

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Lab Infrared Press Mold

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

Related Articles

- Operating of Automatic Lab xrf Pellet Press

- Why Your Sample Prep Fails: The Hidden Flaw in Your Hydraulic Press

- Effective Preparation of Samples for XRF Analysis via Pressed Pellets Method

- Understanding the Technical Aspects of Cold Isostatic Pressing

- Understanding Cold Isostatic Pressing (CIP) and Its Advantages