Manual Lab Press

Laboratory Manual Hydraulic Pellet Press for Lab Use

Item Number : PCMP

Price varies based on specs and customizations

- Working pressure

- 0-40 T

- Piston diameter

- Φ70-Φ130 mm

- Piston stroke

- 30 mm

- Gauge range

- 0-40 Mpa

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Applications

Lab Hydraulic press is widely used in material researching labs,pharmacy,catalytic reaction,ceramics, electronic industries, it is one high efficient equipment for the sample preparing, due to its small footprint, it easy to carry and move, can work inside the vacuum glove box for processing under vacuum environment.

Feature

Manual Lab Hydraulic Press above 60T can be designed according to your needs.

- Small footprint, light weight, easy to carry and move, nice fitting vacuum glove box

- Pressure gauge with double pressure indicator, save pressure converting time

- 12-24T model machine output sample can meet requirement of infrared spectrometer

- 24-40T model machine output sample can meet requirement of fluorescence spectrometer

- Double scale dial to avoid complicated conversions

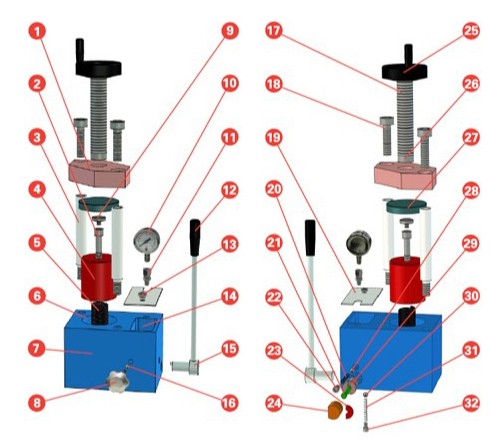

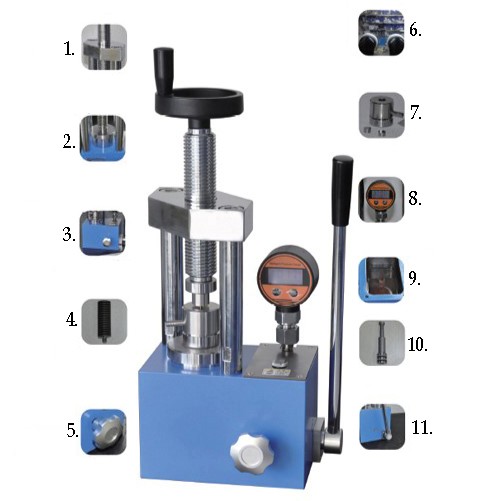

Detail & Parts

- Top board uses electroplated countersunk socket head cap screws, which are beautiful, space saving and smooth.

- Chrome-plated oil cylinder features smooth surface, rust prevention, excellent rubber gasket sealing and leakage-proof.

- Oil sump, mainboard and oil cylinder are integrated on the same mainboard, and no sealing connection is needed.

- Extended tension spring with excell-entresilience ensures that the oil cylinder won't deform easily in 30mm return trip.

- Aluminum alloy hand-wheel,beautiful,practical,sturdy and durable.

- Small size, light weight,leak-proof, easy to handle,suitable for use in glove box.

- Dies are made of quick-cutting steel imported from Japan, featuring quality material, high hardness, non-deformation and long life.

- Digital pressure gauge offers pressure control as accurate as 0.01MPa.

- 0il sump is on the surface of the main unit to facilitate oil cha -nging, and hydraulic filter is installed in the oil circuit.

- Dedicated plunger uses specially customized structure to ensure sealing effect and prevent leakage.

- Pressure device Is placed in the bottom of the main unit, which ensures reasonable angle and saves pressurizing force.

Advantages

- The upper plate adopts electroplated countersunk head hexagonal screws, beautiful and space-saving

- Chrome-plated cylinder, smooth surface, no rust, good sealing rubber ring, no oil leakage

- One-piece main board structure, oil pool, main board, oil cylinder in a body, no seal connection

- Extended pulling spring, good rebound effect, not easy to deformation, can achieve the cylinder 30mm return without deformation

- All aluminum alloy hand wheel, beautiful, practical, not easy to break

- Small size, light weight, no oil leakage, can be used in the glove box

- Mold using Japanese high-speed steel, good material, high hardness, no deformation, long service life

- Digital display pressure gauge, more accurate pressure control, pressure display accuracy of 0.01MPa

- Oil pool outside the host, easy to replace the oil, and the oil circuit increased the hydraulic oil filtration device

- Special plunger, using special custom sealing structure, excellent sealing effect

- Pressurizing device, placed in the lowermost corner of the mainframe, the angle is reasonable, pressurizing force does not tilt back

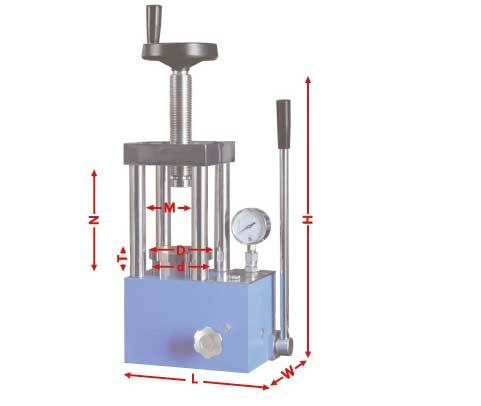

Technical specifications

| Instrument model | PCMP-2T | PCMP-5T | PCMP-12T | PCMP-15T | PCMP-24T | PCMP-30T | PCMP-40T |

|---|---|---|---|---|---|---|---|

| Pressure range | 0-2T (25MPa) | 0-5T(0-31.4MPa) | 0-12T(0-30MPa) | 0-15T(0-30MPa) | 0-24T(0-34MPa) | 0-30T(0-31.5MPa) | 0-40T(0-30MPa) |

| Piston diameter | Φ32mm (d) | Φ45mm (d) | Φ70mm (d) | Φ80mm (d) | Φ95mm (d) | Φ110mm (d) | Φ130mm (d) |

| Integral structure | No sealing connection, oil leakage reduced | No sealing connection, oil leakage reduced | No sealing connection, oil leakage reduced | No sealing connection, oil leakage reduced | No sealing connection, oil leakage reduced | No sealing connection, oil leakage reduced | No sealing connection, oil leakage reduced |

| Pressure gauge | Pressure and pressure intensity display | Pressure and pressure intensity display | Pressure and pressure intensity display | Pressure and pressure intensity display | Pressure and pressure intensity display | Pressure and pressure intensity display | Pressure and pressure intensity display |

| Maximum pressure (T) | 30mm | 30mm | 30mm | 30mm | 30mm | 40mm (T) | 50mm (T) |

| Pressure stability | ≤1MPa/10min | ≤1MPa/10min | ≤1MPa/10min | ≤1MPa/10min | ≤1MPa/10min | ≤1MPa/10min | ≤1MPa/10min |

| Workbench diameter | Φ50mm (D) | Φ80mm (D) | Φ80mm (D) | Φ90mm (D) | Φ105mm (D) | Φ120mm (D) | Φ140mm (D) |

| Number of columns | Two | Two | Two | Two | Four | Four | Four |

| Working space | 85×120mm(M×N) | 96×130mm(M×N) | 96×130mm(M×N) | 140×150mm(M×N) | 80×150mm(M×N) | 92×160mm(M×N) | 106×185mm(M×N) |

| Dimensions | 210×150×350mm(L×W×H) | 225×155×380mm(L×W×H) | 225×155×380mm(L×W×H) | 245×175×390mm(L×W×H) | 245×175×415mm(L×W×H) | 275×195×420mm(L×W×H) | 295×215×500mm(L×W×H) |

| Weight | 12 Kg | 28Kg | 28Kg | 38Kg | 42Kg | 56Kg | 75Kg |

Operation

How to replace accessories and precautions

Before we dive into the step-by-step instructions, it's essential to note that safety is of utmost importance when operating the Manual lab press machine. Always wear protective gloves and eye goggles when handling the machine, and make sure to read the user manual carefully before use.

Step 1: Place the mold in the center of the tablet press

Step 2: Tighten the tablet press oil drain valve clockwise

Step 3: Tighten the screw to fix the mold

Step 4: Shake the handle pressure rod back and forth to reach the required pressure

Step 5: Loosen the oil drain valve counterclockwise to release the pressure

Step 6: Remove the pressed mold from the tablet press

Full range of lab press types

Click to view our full range of lab press products.

Any question? Our experts have helped many laboratories choose their lab press, contact us now!

Full range of types of laboratory press molds

We have a full range of molds for you to choose from, and the molds fit the body perfectly.

If you need molds with special shapes, we can also customize them for you.

Warnings

Operator safety is the top important issue! Please operate the equipment with cautions. Working with inflammable& explosive or toxic gases is very dangerous, operators must take all necessary precautions before starting the equipment. Working with positive pressure inside the reactors or chambers is dangerous, operator must fellow the safety procedures strictly. Extra caution must also be taken when operating with air-reactive materials, especially under vacuum. A leak can draw air into the apparatus and cause a violent reaction to occur.

Designed for You

KinTek provide deep custom made service and equipment to worldwide customers, our specialized teamwork and rich experienced engineers are capable to undertake the custom tailoring hardware and software equipment requirements, and help our customer to build up the exclusive and personalized equipment and solution!

Would you please drop your ideas to us, our engineers are ready for you now!

Trusted by Industry Leaders

FAQ

What Is A Lab Press?

What Are The Advantages Of Using A Manual Press?

How Does A Manual Press Work?

What Types Of Tasks Can Be Performed Using A Manual Press?

What Is The Purpose Of A Hydraulic Press In Lab?

What Are The Applications Of Pellet Presses?

What Are Different Type Of Lab Presses?

How Does A Pellet Press Work?

What Is Manually Operated Lab Press?

What Are The Benefits Of Using A Pellet Press?

What Factors Should Be Considered When Selecting A Pellet Press?

4.9 / 5

This hydraulic press is an excellent choice for lab applications. It's simple to operate and provides precise pressure control, ensuring consistent and repeatable results.

4.8 / 5

The manual hydraulic pellet press is a valuable addition to our lab. It's easy to use and delivers accurate results, making it an essential tool for sample preparation.

4.7 / 5

The hydraulic press is a reliable and durable piece of equipment. We've been using it for several years without any issues, and it continues to perform flawlessly.

4.8 / 5

The manual hydraulic pellet press is an excellent investment for any lab. It's affordable, easy to use, and produces high-quality results.

4.9 / 5

We've been using the hydraulic press for over a year now, and it's been an invaluable tool in our research. It's easy to operate and provides precise pressure control, which is crucial for our experiments.

4.7 / 5

The hydraulic press is a great addition to our lab. It's compact and easy to use, and it produces consistent results. We're very happy with our purchase.

4.8 / 5

The hydraulic press is a great choice for labs with limited space. It's small and lightweight, yet it still delivers powerful and precise pressing.

4.7 / 5

We recently purchased the hydraulic press for our lab, and we're very impressed with its performance. It's easy to use and maintain, and it produces high-quality results.

4.9 / 5

The hydraulic press is a must-have for any lab that needs to prepare samples for analysis. It's easy to operate and provides consistent and accurate results.

4.8 / 5

The hydraulic press is a great investment for any lab. It's durable, reliable, and produces high-quality results. We're very happy with our purchase.

4.7 / 5

The hydraulic press is a valuable addition to our lab. It's easy to use and provides precise pressure control, making it ideal for a variety of applications.

4.9 / 5

The hydraulic press is a great choice for labs that need a reliable and affordable solution for sample preparation. It's easy to use and produces consistent results.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Laboratory Manual Hydraulic Pellet Press for Lab Use

Efficient Manure Lab Hydraulic Press with Safety Cover for sample preparation in material research, pharmacy, and electronic industries. Available in 15T to 60T.

kbr pellet press 2t

Introducing the KINTEK KBR Press - a handheld laboratory hydraulic press designed for entry-level users.

Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

Controlled environment lab press machine for glove box. Specialized equipment for material pressing and shaping with high precision digital pressure gauge.

Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

Efficiently prepare samples with the Electric Hydraulic Press. Compact and portable, it's perfect for labs and can work in a vacuum environment.

Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

Efficiently prepare your samples with our Automatic Heated Lab Press. With a pressure range up to 50T and precise control, it's perfect for various industries.

Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

Efficiently process heat-pressing samples with our Integrated Manual Heated Lab Press. With a heating range up to 500°C, it's perfect for various industries.

Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

Efficiently prepare your samples with our Split Manual Heated Lab Press. With a pressure range up to 40T and heating plates up to 300°C, it's perfect for various industries.

Laboratory Hydraulic Press Lab Pellet Press for Button Battery

Efficiently prepare samples with our 2T Button Battery Press. Ideal for material research labs and small-scale production. Small footprint, lightweight, and vacuum-compatible.

Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

The Manual Heat Press is a versatile piece of equipment suitable for a variety of applications, operated by a manual hydraulic system that applies controlled pressure and heat to the material placed on the piston.

Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

Enhance your lab's precision with our lab press for vacuum box. Press pills and powders with ease and precision in a vacuum environment, reducing oxidation and improving consistency. Compact and easy to use with a digital pressure gauge.

Electric Heated Hydraulic Vacuum Heat Press for Lab

The Electric Vacuum Heat Press is a specialized heat press equipment that operates in a vacuum environment, utilizing advanced infrared heating and precise temperature control for high quality, rugged and reliable performance.

Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

The Automatic High Temperature Heat Press is a sophisticated hydraulic hot press designed for efficient temperature control and product quality processing.

Laboratory Hydraulic Press Split Electric Lab Pellet Press

Efficiently prepare samples with a split electric lab press - available in various sizes and ideal for material research, pharmacy, and ceramics. Enjoy greater versatility and higher pressure with this portable and programmable option.

Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

The lab press for vacuum box is a specialized piece of equipment designed for laboratory use. Its main purpose is to press pills and powders according to specific requirements.

Ball Press Mold for Lab

Explore versatile Hydraulic Hot Press molds for precise compression molding. Ideal for creating various shapes and sizes with uniform stability.

Laboratory Vertical Water Circulating Vacuum Pump for Lab Use

Looking for a reliable water circulating vacuum pump for your lab or small-scale industry? Check out our Vertical Water Circulating Vacuum Pump with five taps and a larger air sucking amount, perfect for evaporation, distillation, and more.

1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

KT-17A Controlled atmosphere furnace: 1700℃ heating, vacuum sealing technology, PID temperature control, and versatile TFT smart touch screen controller for laboratory and industrial use.

Related Articles

Manual Hydraulic Presses for Laboratory Use: A Comprehensive Guide

Explore the intricacies of manual hydraulic presses in labs, including operation, benefits, and comparison with automatic models. Ideal for those seeking detailed insights on sample preparation and cost-effectiveness.

Manual Lab Hydraulic Pellet Press: Comprehensive Guide to High-Quality Pellet Preparation

Explore the detailed guide on using a Manual Lab Hydraulic Pellet Press for high-quality pellet preparation in spectral analyses. Learn about features, operation, and maintenance for optimal performance.

Comprehensive Guide to Manual Hydraulic Pellet Press

A manual hydraulic pellet press is a valuable tool in the laboratory for preparing pellets with a smooth and homogeneous surface for spectral analyses. It is commonly used in applications such as X-ray fluorescence analysis or infrared spectroscopy for elemental analysis.

Manual Hydraulic Pellet Press: An Efficient Tool for Spectral Analyses Preparation

The manual hydraulic pellet press offers several key features that make it a valuable tool for laboratory applications. Some of the main features include:Availability of pressing tools in different diameters: 40mm, 32mm, and 15mm;Availability of pressing tools in different diameters: 40mm, 32mm, and 15mm;Designed pressure force display in 10 kN steps;Ease of operation via hand lever;Convenience in cleaning;Single-stage piston stroke of maximum 25mm ect.

Understanding Hydraulic Pellet Press: Working Mechanism and Applications

A hydraulic press, also known as a Bramah press, is a machine that uses fluid pressure to generate a force. This force can be used to compress or mold materials. Hydraulic presses are commonly used in manufacturing and industrial applications due to their ability to exert a large amount of force while still being easy to operate.

Automatic Hydraulic Press: The Ultimate Guide for Efficient Sample Preparation and Industrial Processes

Discover the world of automatic hydraulic presses, from their versatile applications in industrial XRF and laboratory sample manipulation to their role in large-scale manufacturing, hot embossing, laminating, and polymer melting. Learn about their benefits, features, and how they revolutionize sample preparation and industrial processes.

Operating of Automatic Lab xrf Pellet Press

How to use the Automatic Lab xrf Pellet Press, including steel ring, plastic ring, boric acid mold

Applications and Importance of Hydraulic Press in Laboratories

A hydraulic press is a machine that uses the pressure generated in a confined fluid to configure metals, plastics, rubber, and other materials. Its operation is governed by Pascal’s principle, which states that pressure applied to a confined fluid is transmitted unaltered throughout the fluid.

A Comprehensive Guide on Pressing XRF Pellets Using a KinTek Automatic Hydraulic Press

XRF (X-ray fluorescence) analysis is a powerful technique used in various industries for material analysis. One crucial step in the XRF analysis process is the preparation of high-quality XRF pellets. These pellets serve as the sample for analysis and need to be properly pressed to ensure accurate results.

Understanding the Functioning and Applications of a Hydraulic Pellet Press

A hydraulic press is a compression device that makes use of an exerted force placed upon a fluid, to create a resulting force according to Pascal’s Law. It was actually invented by Joseph Bramah, so is also known as the Bramah Press.

What is lab hydraulic press

A lab hydraulic press is a machine that uses a fluid to generate a force. The force is generated by a piston that is moved by the fluid. The fluid can be water, oil, or a synthetic fluid. The force generated by the press can be used to compress a variety of materials.

Hydraulic Presses vs. Mechanical Presses Which is Right for Your Laboratory

Hydraulic and mechanical presses are two commonly used types of presses, each with its own set of advantages and disadvantages. Hydraulic presses use hydraulic cylinders to apply force, while mechanical presses use a mechanical lever or cam to apply force.