Main Features of Manual Hydraulic Pellet Press

Table of Contents

- Main Features of Manual Hydraulic Pellet Press

- Availability of pressing tools in different diameters: 40mm, 32mm, and 15mm

- Variable pressure force up to 250 kN

- Designed pressure force display in 10 kN steps

- Ease of operation via hand lever

- Convenience in cleaning

- Single-stage piston stroke of maximum 25mm

- Automatic pressure relief in case of overstress

- Solid and compact with impact-resistant cladding

- Procedure of Using Manual Hydraulic Pellet Press

- Recommendation for Comminution of Solid Samples

The manual hydraulic pellet press offers several key features that make it a valuable tool for laboratory applications. Some of the main features include:

Availability of pressing tools in different diameters: 40mm, 32mm, and 15mm

The manual hydraulic pellet press provides pressing tools in different diameters, allowing for flexibility in pellet size. With options of 40mm, 32mm, and 15mm, researchers can choose the appropriate diameter for their specific needs.

Variable pressure force up to 250 kN

The manual hydraulic pellet press offers variable pressure force of up to 250 kN. This allows for precise control over the pressure applied during pellet formation, ensuring consistent and reliable results.

Designed pressure force display in 10 kN steps

To enhance ease of use and accuracy, the manual hydraulic pellet press features a clearly designed pressure force display in 10 kN steps. This allows researchers to monitor and adjust the pressure force with precision.

Ease of operation via hand lever

Operating the manual hydraulic pellet press is made simple and convenient with the use of a hand lever. This ergonomic design allows for effortless pressing of pellets, reducing user fatigue and improving overall efficiency.

Convenience in cleaning

The manual hydraulic pellet press is designed for easy cleaning. Its compact and solid construction, along with impact-resistant cladding, ensures that cleaning is quick and hassle-free, saving valuable time in the laboratory.

Single-stage piston stroke of maximum 25mm

With a single-stage piston stroke of up to 25mm, the manual hydraulic pellet press offers sufficient depth for pellet formation. This allows researchers to create pellets of the desired thickness for their specific applications.

Automatic pressure relief in case of overstress

To ensure safety and prevent damage, the manual hydraulic pellet press is equipped with an automatic pressure relief mechanism in case of overstress. This feature protects both the equipment and the user, providing peace of mind during operation.

Solid and compact with impact-resistant cladding

The manual hydraulic pellet press is built to withstand the demands of laboratory use. Its solid and compact design, coupled with impact-resistant cladding, ensures durability and longevity, making it a reliable tool for pellet pressing.

In conclusion, the manual hydraulic pellet press offers a range of features that make it an essential tool for laboratory applications. With its variable pressure force, ease of operation, and convenient cleaning, researchers can achieve precise and consistent results in pellet formation. The automatic pressure relief and solid construction further enhance the safety and durability of the equipment. Whether for FTIR analysis, XRF sample preparation, or other applications, the manual hydraulic pellet press is a valuable asset in any laboratory setting.

Procedure of Using Manual Hydraulic Pellet Press

1. Fill in the sample

Before using the manual hydraulic pellet press, it is important to prepare the working area. Check the hydraulic oil quantity to ensure it is sufficient for operation. The hydraulic oil should be filled up to 2/3 of the height of the lower frame. If the oil quantity is insufficient, add hydraulic oil to the oil injection hole of the lower stand until it reaches 2/3 of the height of the lower stand. Additionally, check the lubrication between the column shaft and the guide frame and apply lubrication if necessary for smooth operation.

2. Close the magnetically-held door

To operate the manual hydraulic pellet press, start by ensuring that the area around the press is clear and free of obstructions. Place the workpiece, such as a pellet die containing a sample material, on the piston. Make sure the workpiece is centered on the piston. Then, slowly turn the leadscrew at the top of the press to bring the nose of the leadscrew onto the top of the workpiece. This will help align the workpiece properly.

3. Build-up the desired pressure using the hand lever

Once the workpiece is properly positioned, use the handle to pump hydraulic oil into the piston and start applying a load. Pump the handle slowly until the desired load or pressure is reached. The pressure force can be varied up to a maximum of 250 kN. A clearly designed pressure force display in 10 kN steps is provided to help monitor the pressure.

When the desired load has been achieved, turn the release valve to release the pressure. This will ensure the safe removal of the workpiece. The manual hydraulic pellet press allows for a single-stage piston stroke of up to 25 mm.

It is important to note that the procedure for using the manual hydraulic pellet press is the same regardless of the object being pressed. Paying attention to the positioning of the workpiece and the applied load is crucial for successful operation.

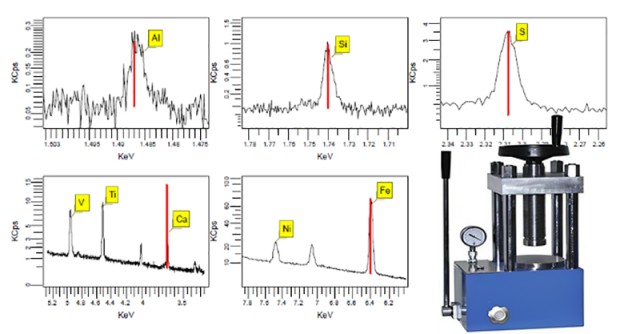

The manual hydraulic pellet press is an ideal tool for preparing pellets with a smooth and homogeneous surface for spectral analyses such as X-ray fluorescence analysis or infrared spectroscopy for elementary analysis. It is suitable for manufacturing both solid and highly permeable pellets of solid samples. The press offers variable pressure force up to 250 kN and features a simple operation via a hand lever. It is also easy to clean and has a solid and compact design with impact-resistant cladding. Pressing tools with different diameters are available for different pellet sizes.

Recommendation for Comminution of Solid Samples

Use of Vibrating Cup Mill for extremely fast size-reduction of hard, brittle and fibrous materials down to analytical fineness

Pressing powder into pellets is a more rigorous sample preparation than pouring loose powders into a sample cup. The process includes grinding a sample into a fine powder, ideally to a grain size of < 75um, mixing it with a binding/grinding aid, and then pressing the mixture in a die at between 20 and 30T to produce a homogeneous sample pellet. The binding/grinding aid is usually a cellulose wax mixture and combines with the sample in a proportion of 20%-30% binder to sample.

Grinding machines

The two most common types of grinding equipment are vibratory mills and planetary mills. Both types of grinding equipment can grind samples to a fine powder and are suitable for different industries. The type of vibratory mill is usually expressed in terms of sample size, with 300g, 200g, 100g, 50g, 10g, etc. They are also available in 1 sample, 2 samples, and 3 samples at a time.

Grinding bowl

The choice of a suitable mortar vessel is important when crushing and grinding, especially when analyzing trace elements. Commonly used materials are generally classified as: hard chromium steel (affecting Fe, Cr, Ni, Mn, Si, etc.), tungsten carbide (affecting W, Co, etc.), agate (affecting Si), zirconium oxide (affecting Zr), hot-pressed sintered corundum (affecting Al), etc.

It's as easy as this:

- Fill in the sample

- Close the magnetically-held door

- Build-up the desired pressure using the hand lever - that's it.

For the comminution of the solid samples - dry or in suspension - KinTek recommends the Vibrating Cup Mill – ideal for extremely fast size-reduction of hard, brittle and fibrous materials down to analytical fineness.

Samples can be classified as solids, powders, and liquids according to the original form of the sample, and samples are processed in different ways. We will present a series on: powder pressed flake preparation, powder fused flake preparation, and block sample preparation. This article introduces a few of the common methods used in powder compacting, plastic ring compacting, boric acid rimmed priming compacting, and steel ring compacting.

Sample preparation process

Powder compacting is a common method of sample preparation for X-ray fluorescence spectroscopy. The general sample preparation procedure is that the sample is crushed, dried, processed to a certain particle size by grinding equipment, and finally pressed into a stable disc by pressing equipment.

If you are interested in this product you can browse our company website:https://kindle-tech.com/thematics/lab-hydraulic-press, as an industry-leading laboratory equipment manufacturer, we are committed to providing the most advanced and high-quality laboratory equipment solutions. Whether you are engaged in scientific research, teaching or industrial production, our products will meet your needs for accurate and reliable laboratory equipment.

Related Products

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

Related Articles

- Operating of Automatic Lab xrf Pellet Press

- Understanding the Functioning and Applications of a Hydraulic Pellet Press

- A Comprehensive Guide on Pressing XRF Pellets Using a KinTek Automatic Hydraulic Press

- Automatic Hydraulic Press: The Ultimate Guide for Efficient Sample Preparation and Industrial Processes

- Applications and Importance of Hydraulic Press in Laboratories