Introduction

Table of Contents

XRF (X-ray fluorescence) analysis is a powerful technique used in various industries for material analysis. One crucial step in the XRF analysis process is the preparation of high-quality XRF pellets. These pellets serve as the sample for analysis and need to be properly pressed to ensure accurate results. In this comprehensive guide, we will explore the use of the KinTek Automatic Hydraulic Press for XRF pellet pressing. We will delve into the process, tips for success, and the importance of using this advanced press for reliable XRF analysis. So, let's dive in and master the art of XRF pellet pressing!

Defining XRF Pellet Pressing

Understanding XRF pellet pressing

XRF pellet pressing is the process of converting powdered samples into flat discs for chemical analysis. These discs are then used for X-ray fluorescence (XRF) analysis, which is a non-destructive method of identifying the elements present in a sample. XRF pellet pressing is crucial in ensuring accurate results for XRF analysis.

The process of making pressed pellets for XRF analysis involves grinding the sample to a fine particle size, mixing it with a binder/grinding aid, pouring the mixture into a pressing die, and then pressing the sample at a pressure of between 15 and 35T. The resulting pellet or tablet is then ready for analysis.

Importance of XRF pellet pressing for XRF analysis

XRF analysis requires instruments that are sensitive and stable to achieve accurate results. While advances in technology have improved the performance of XRF instruments, sample preparation techniques remain a common source of error in XRF analysis.

XRF pellet pressing offers a cost-effective, quick, and high-quality method of preparing samples for analysis. Pressed pellets ensure accurate quantification of sample composition, leading to more reliable results.

Key considerations for XRF pelletizing include the particle size of the sample, the choice of binder, the dilution ratio, the amount of pressure applied to the sample, the thickness of the final pellet, and the prevention of sample contamination. By carefully considering these factors and using high-quality pelletizing products, such as pellet binders, dies, and hydraulic presses, laboratories can ensure that their XRF analysis applications are carried out to the highest standard.

In conclusion, XRF pellet pressing is an essential process for many industries. By following the steps outlined in this guide and considering the key factors in XRF pelletizing, laboratories can produce accurate and consistent XRF pellets for chemical analysis using a KinTek Automatic Hydraulic Press.

Exploring the Automatic Hydraulic Press

An automatic hydraulic press is a valuable tool in laboratories, offering improved workflow and increased accuracy in various tasks. Unlike manual counterparts, automatic hydraulic presses can operate autonomously once programmed, allowing technicians to focus on other tasks. These presses are designed to be less laborious and more consistent, eliminating variable factors during use.

Hydraulic Mini Press

A hydraulic mini press is a compact and portable version of a hydraulic press. It utilizes hydraulic power to generate force. The press works by utilizing pressure generated by a pump to move an oil-filled plunger. This plunger then compresses fluids or gases, exerting force on an object. The pressure in the system is regulated by valves that can be adjusted based on the specific requirements of the task at hand.

Types of Hydraulic Press Explained

Laboratory presses come in various sizes and configurations, and the choice of which one to use depends on the intended application, workflow compatibility, and user requirements.

Manual Hydraulic Press

A manual hydraulic press operates using a hand-operated lever to apply load to a sample. It features a mechanical lever that controls a piston within a cylinder containing hydraulic oil. This piston exerts pressure on a die or head containing the desired material. By manipulating the lever, the pressure from the cylinder can be increased or decreased until the optimal amount of force is achieved for a specific task.

Automatic Hydraulic Press

Automatic hydraulic presses are commonly used in industrial XRF applications and other laboratory sample manipulation activities. They are also suitable for small and large-scale manufacturing practices, including hot embossing, laminating, and melting polymers for thin films. These presses offer versatility and efficiency in sample preparation.

KINTEK's automatic laboratory press is a prime example, featuring a sleek design with an LED touchscreen interface for easy operation. Its hydraulic system generates precise and consistent force, enhancing the efficiency of sample preparation. Unlike manual hydraulic presses, automatic presses are operated through a button. The general mechanics of both types are similar, where the desired load is set and fulfilled by the pump. However, an automatic press often includes automated actions for pressing and releasing the die.

Hydraulic mini presses and automatic hydraulic presses are valuable tools in laboratories, offering efficiency, accuracy, and versatility in various applications. Their ability to generate precise and consistent force enhances workflow and productivity. Whether in small-scale tasks or large-scale manufacturing, automatic hydraulic presses prove to be valuable assets.

Process of Pressing XRF Pellets Using the KinTek Automatic Hydraulic Press

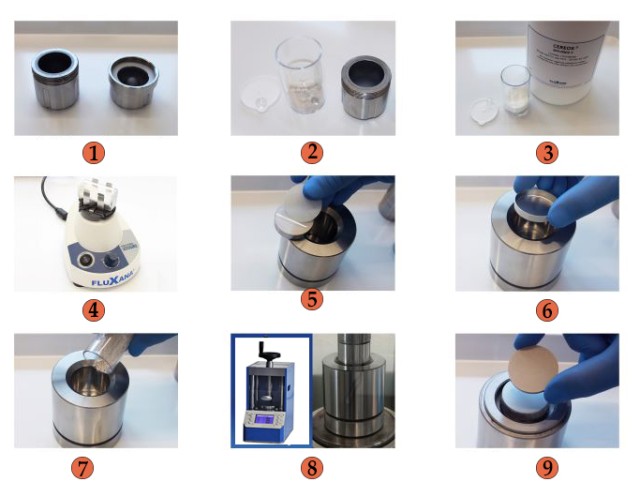

XRF pellet pressing is an essential process for many industries, including mining, geology, and metallurgy. It involves converting powdered samples into flat discs for chemical analysis using a KinTek Automatic Hydraulic Press. This press utilizes hydraulic pressure to compress the sample into a small, flat disc. Here is a step-by-step guide on how to press XRF pellets using the KinTek Automatic Hydraulic Press.

Preparation for the process

Before you begin the XRF pellet pressing process, gather all the necessary equipment. You will need a KinTek Automatic Hydraulic Press, XRF pellet dies, a pellet pressing lubricant, and a powdered sample.

Setting up the press

- Place the KinTek Automatic Hydraulic Press on a stable and level surface.

- Ensure that the press is connected to a reliable power source.

- Familiarize yourself with the press's control panel and functions.

Sample preparation

- Prepare the powdered sample according to the specific requirements of your analysis.

- Ensure that the sample is finely ground and homogeneous for accurate results.

- Measure the appropriate amount of sample for the desired pellet size.

Loading the die

- Insert the desired XRF pellet die into the press.

- Place a piece of clean, lint-free paper or film on the bottom of the die cavity.

- Carefully pour the prepared sample into the die cavity, ensuring it is evenly distributed.

Application of lubricant

- Apply a small amount of pellet pressing lubricant to the top of the sample in the die cavity.

- The lubricant helps reduce friction during the pressing process and aids in easy pellet removal.

Executing the pressing cycle

- Close the press and secure it properly.

- Set the desired pressure and duration on the control panel.

- Start the pressing cycle by activating the press.

- The press will automatically apply the programmed pressure and duration to the sample.

Pellet removal

- Once the pressing cycle is complete, release the pressure and open the press.

- Carefully remove the XRF pellet from the die using a non-metallic tool.

- Handle the pellet with care to avoid any damage or contamination.

Procedure repetition

- Clean the die cavity and remove any residue before repeating the pressing process.

- Repeat the steps for each additional XRF pellet required.

By following these steps, you can successfully press XRF pellets using the KinTek Automatic Hydraulic Press. Remember to use high-quality dies, prepare the sample properly, and follow the manufacturer's instructions for the press. With these tips, you'll be able to produce accurate and consistent XRF pellets for chemical analysis.

Tips for Successful XRF Pellet Pressing

XRF pellet pressing is an essential process in many industries for accurate chemical analysis. To ensure successful XRF pellet pressing, there are several key tips that you should follow:

1. Use of high-quality XRF pellet dies

Always use high-quality XRF pellet dies to ensure consistent pellet shapes and sizes. The dies should be constructed from high-quality stainless steel, with the pressing face perfectly flat and smooth. This ensures that the sample is pressed uniformly and accurately.

2. Ensuring homogeneity and clump-free nature of the sample

Before loading the sample into the die, make sure that it is homogeneous and free of any clumps. This can be achieved by grinding the sample into a fine powder and thoroughly mixing it. Homogeneity ensures that the analysis results are representative of the entire sample.

3. Application of pellet pressing lubricant

To prevent the sample from sticking to the die, apply a small amount of pellet pressing lubricant to the top of the sample. This lubricant reduces friction during the pressing process and allows for easy removal of the pellet from the die.

4. Adherence to manufacturer’s instructions for the KinTek automatic hydraulic press

If you are using a KinTek automatic hydraulic press for XRF pellet pressing, it is important to follow the manufacturer’s instructions. This ensures that you are using the press correctly and optimizing the pressing parameters for accurate results.

5. Usage of appropriate personal protective equipment

Always wear appropriate personal protective equipment, such as gloves and safety glasses, when working with powdered samples. This protects you from potential hazards and ensures a safe working environment.

By following these tips, you can achieve successful XRF pellet pressing and obtain accurate and consistent results for your chemical analysis. Remember to use high-quality dies, prepare the sample properly, and follow the manufacturer’s instructions for the press. With these guidelines, you can ensure the quality of your XRF analysis.

Conclusion

Pressing XRF pellets using a KinTek Automatic Hydraulic Press is a crucial step in XRF analysis. It ensures accurate and reliable results by creating homogeneous and clump-free pellets. The automatic hydraulic press simplifies the process with its user-friendly functionality and precise control. By following the proper procedure, including sample preparation, die loading, lubricant application, and pressing cycle execution, business professionals can achieve successful XRF pellet pressing. It is important to use high-quality XRF pellet dies, adhere to manufacturer's instructions, and wear appropriate personal protective equipment for a safe and efficient pressing process.

Related Products

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

- kbr pellet press 2t

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- XRF & KBR steel ring lab Powder Pellet Pressing Mold for FTIR

Related Articles

- Understanding Cold Isostatic Pressing: Process, Comparisons, and Applications

- Why Your Sample Prep Fails: The Hidden Flaw in Your Hydraulic Press

- Understanding Cold Isostatic Pressing (CIP) and Its Advantages

- What is xrf analysis and how to making pressed xrf pellets

- Effective Preparation of Samples for XRF Analysis via Pressed Pellets Method