In the cutting-edge landscape of laboratory technology, the automated XRF and KBR pellet press stand as a testament to precision and efficiency. With programmed pressurization and streamlined operations, these fully automatic desktop presses redefine the standards for high-end laboratories. Join us as we navigate through the automated operating procedures, unveiling a world where loading and ejection are simplified, operating time is shortened, and work efficiency reaches unprecedented heights.

Operation steps

1.Open the upper cantilever.

2.Remove the upper pressure rod.

3.Load the sample into the built-in mold.

4.Put on the push rod.

5.Close the boom.

6.Tighten the screw to hold the mold.

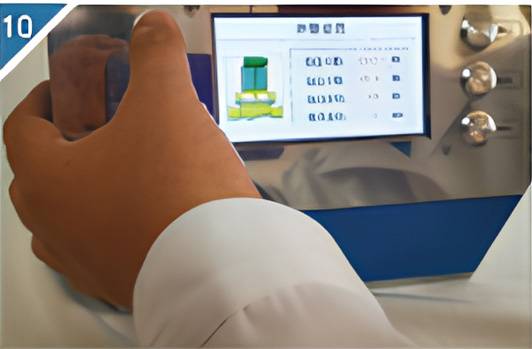

7.Press the (Settings) button to enter the setting interface.

Press the "+" key to increase the parameter value.

9.Press the "-" key to reduce the parameter value.

10.Press the "Settings" key repeatedly to return to the operation interface.

11.Press the "Preparation" key to start pressurization.

12.The equipment automatically releases pressure after being pressurized according to the set parameters.

13.In case of emergency, press the "Stop" button to terminate the operation.

14.Open the upper cantilever.

15.Press the "Eject" button to eject the sample.

16.Remove the sample.

As we conclude our journey through the automated laboratory XRF and KBR pellet press operating procedures, the fully automatic desktop press emerges as a game-changer. Programmed pressurization not only simplifies the complex but also shortens operating time, enhancing work efficiency. The LCD display serves as a beacon of intuitiveness, providing a clear interface for users. In the realm of high-end laboratories, these automated procedures not only streamline operations but also set a new standard for precision and convenience. The automated XRF and KBR pellet press revolutionize laboratory work, showcasing a future where technology meets efficiency seamlessly.

Related Products

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

- kbr pellet press 2t

- XRF & KBR plastic ring lab Powder Pellet Pressing Mold for FTIR

- XRF & KBR steel ring lab Powder Pellet Pressing Mold for FTIR

Related Articles

- A Comprehensive Guide on Pressing XRF Pellets Using a KinTek Automatic Hydraulic Press

- Understanding Cold Isostatic Pressing: Process, Comparisons, and Applications

- Guide for Xrf Pellet Press

- Why Your Sample Prep Fails: The Hidden Flaw in Your Hydraulic Press

- Understanding the Technical Aspects of Cold Isostatic Pressing