Introduction

Table of Contents

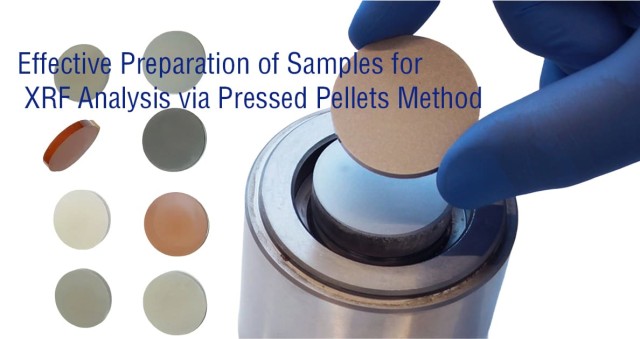

Welcome to our blog post on the effective preparation of samples for XRF analysis using the pressed pellets method. If you're involved in the field of analytical chemistry or materials analysis, then you probably understand the importance of sample preparation in obtaining accurate and reliable results. In this article, we will dive into the details of the pressed pellets method, its advantages, and the step-by-step procedure for creating high-quality pressed pellets. So, let's get started and learn how to optimize your sample preparation for XRF analysis!

Understanding the Pressed Pellets Method for XRF Analysis

Popularity and advantages of the method

The process of making pressed pellets for XRF analysis is a popular and widely used method. It offers several advantages over other sample preparation techniques. One of the main advantages is that it produces high-quality results. Pressed pellets have a higher signal-to-noise ratio compared to loose powder samples, allowing for the detection of even the lightest elements.

When quantifying the elemental composition, significant discrepancies can be observed between the expected values and the results obtained from loose powder samples. However, when the same batch of material is used to prepare a pressed pellet, these discrepancies disappear. This makes pressed pellets a more reliable and accurate method for XRF analysis.

Another advantage of using pressed pellets is the ease of automation and higher throughput in laboratories. This method lends itself well to simple and cost-effective automation, making it suitable for laboratories that require a higher sample throughput.

Detailed procedure for creating pressed pellets

The process of creating pressed pellets for XRF analysis involves several steps. Firstly, the sample is ground to a fine particle size. This can be done using a grinding or mixing vessel. The ground sample is then mixed with a binder or grinding aid. The choice of binder is important and should be selected based on the specific requirements of the analysis.

Once the sample is mixed with the binder, it is poured into a pressing die. The pressing die is then subjected to a pressure of between 15 and 35 tons. This pressure helps to compact the sample and form it into a pellet or tablet shape. The resulting pellet is then ready for analysis using XRF spectroscopic measurement.

It is important to note that the success and consistency of the pressed pellet method depend on several factors. These include the particle size of the sample, the choice of binder, the dilution ratio, the amount of pressure applied, and the thickness of the final pellet. Consistency in the preparation procedures is key to achieving reliable and accurate results.

In conclusion, the pressed pellets method for XRF analysis is a popular and advantageous technique. It offers high-quality results, better accuracy in elemental composition, and is suitable for automation in high-throughput laboratories. By following the proper procedure and considering important factors, such as particle size and binder choice, consistent and reliable results can be achieved.

Key Considerations for Pressed Pellets Sample Preparation

Importance of sample particle size

One of the key aspects of preparing pressed pellets is to make sure that the sample is ground to a particle size of < 75µm, but < 50µm is ideal. Small particle size is important in producing pellets that provide the best analytical results because it affects how the sample will compress and bind together when pressed. Samples with larger or variable particle sizes can lead to heterogeneities in the sample, which can result in inaccurate analysis. It is also important to note that the sampling depth or critical escape depth for elements contained in a sample is energy-dependent and different for every element. Longer wavelength elements such as Na will have smaller escape depths than shorter wavelength elements such as Fe. This means that Na analysis is only sampling the first 10µm or so of a sample and thus more susceptible to sample heterogeneities on that scale.

Choice of binder for the sample

The binder used in the sample preparation process is crucial for achieving accurate and consistent results. The binder helps to hold the sample particles together during the pressing process and prevents the pellets from breaking. A common binder used is a cellulose wax mixture, which is typically mixed with the sample in a proportion of 20%-30% binder to sample. Using a consistent amount of binder for every sample is important to ensure accuracy levels and avoid over-diluting a sample. Weak pellets can break, damaging the spectrometer and destroying the sample.

Determining the sample dilution ratio

In addition to the type of binder used, the quantity of binder is also important in sample preparation. The amount of binder used must remain the same for every sample to ensure accuracy levels and avoid over-diluting a sample. For most samples, a large amount of binder is used to ensure strong pellets that do not break during the pressing process.

Choosing the right pressure for pressing

The amount of pressure applied to the sample during the pressing process is another key consideration. The recommended pressure range for pressing is between 15 and 35T. The pressure applied should be consistent for every sample to ensure accurate and reproducible results. Pressing with too little pressure may result in weak pellets, while pressing with too much pressure can cause sample damage and affect the analysis.

Consideration of the pellet thickness

The thickness of the final pellet is also an important factor to consider. The pellet should be thick enough to provide a representative sample for analysis but not too thick that it affects the analysis. The recommended thickness for the pellet is typically around 4-5mm.

In summary, the key considerations for pressed pellets sample preparation include the particle size of the sample, the choice of binder, the dilution ratio, the amount of pressure applied to the sample, and the thickness of the final pellet. These factors play a crucial role in achieving accurate and reproducible results in XRF analysis.

Conclusion

In conclusion, the pressed pellets method is a highly effective technique for sample preparation in XRF analysis. Its popularity stems from the numerous advantages it offers, such as producing homogeneous pellets with consistent composition and reducing the risk of contamination. By following the detailed procedure, including the proper particle size, binder choice, dilution ratio, pressure, and pellet thickness, accurate and reliable results can be obtained. This method simplifies the preparation process, saves time, and ensures the integrity of the sample, making it a preferred choice for professionals in various industries.

If you are interested in this product you can browse our company website:https://kindle-tech.com/thematics/xrf-pellet-press, as an industry-leading laboratory equipment manufacturer, we are committed to providing the most advanced and high-quality laboratory equipment solutions. Whether you are engaged in scientific research, teaching or industrial production, our products will meet your needs for accurate and reliable laboratory equipment.

Related Products

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- XRF & KBR steel ring lab Powder Pellet Pressing Mold for FTIR

- XRF & KBR plastic ring lab Powder Pellet Pressing Mold for FTIR

- XRF Boric Acid Lab Powder Pellet Pressing Mold for Laboratory Use

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications