introduction

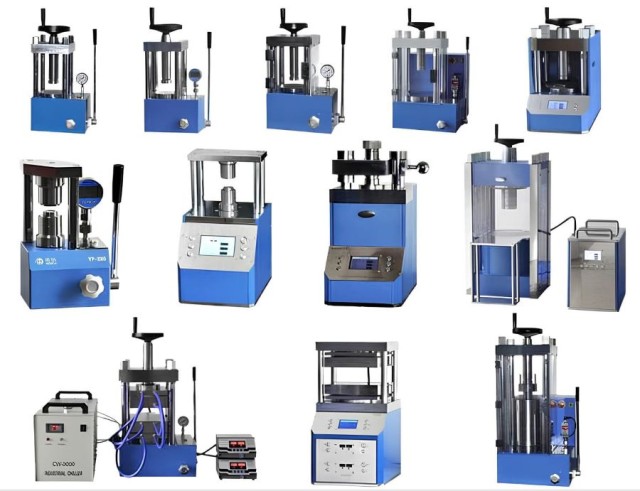

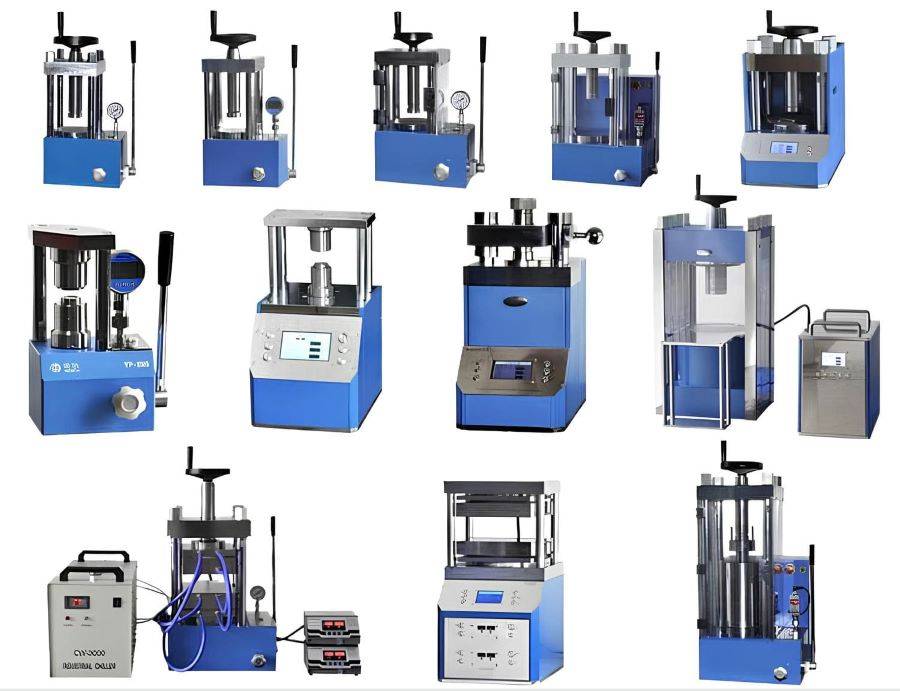

Hydraulic Lab Press is widely used in material researching labs,pharmacy,catalytic reaction,ceramics, electronic industries, it is one high efficient equipment for the sample preparing, due to its small footprint, it easy to carry and move, can work inside the vacuum glove box for processing under vacuum environment. Hydraulic Heat Lab Press can also process hot press function with heating plates, which can serve the particular material processing.

The Hydraulic Heat Lab Press can heat the sample during the pressing process to meet some laboratory sample preparation requirements.

Principle

Lab Hydraulic presses are used in a wide range of industries to assemble, bend, crush, or otherwise alter the shapes of materials.

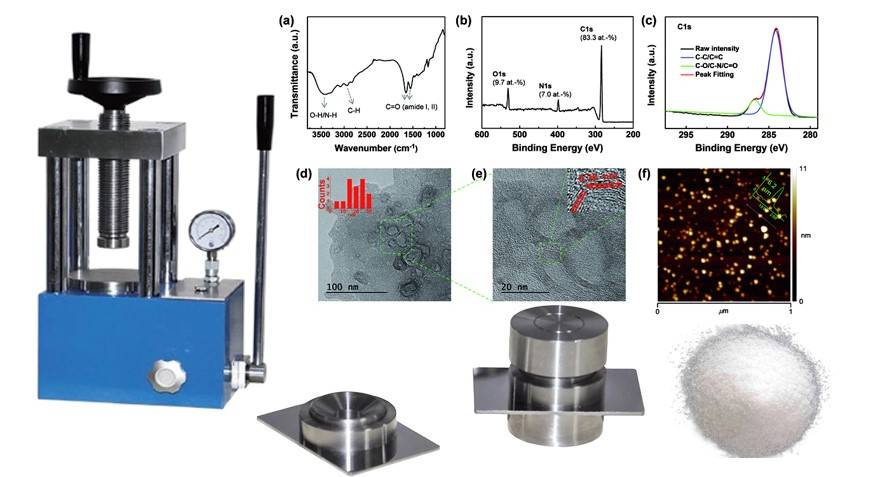

A lab hydraulic press is a machine that uses a fluid to generate a force. The force is generated by a piston that is moved by the fluid. The fluid can be water, oil, or a synthetic fluid. The force generated by the press can be used to compress a variety of materials.

Hydraulic presses can exert enormous force, often in the range of hundreds of tons. Hydraulic presses are used in a wide range of industries to assemble, bend, crush, or otherwise alter the shapes of materials. They are most often used to compact or crush objects into a denser form, such as with recycling. There are many different types of hydraulic presses, each designed for a specific purpose. Some common examples include assembly presses, which are used to put together parts or products; bending presses, which are used to change the shape of materials; and stamping presses, which are used to create indentations or impressions in materials.

With the help of dies, molds, or heavy duty tools and workpieces, these presses can be used to create an exceptional variety of objects.Hydraulic presses are powerful machines that can be used to straighten, bend, or stamp metal workpieces. With the help of dies, molds, or heavy duty tools, these presses can be used to create an exceptional variety of objects. Hydraulic presses have proven useful due to their ability to apply a substantial compressive force to workpieces, making them ideal for shaping metal billets into desired shapes.

Application

Laboratory Hydraulic press is widely used in:

- material researching labs

- pharmacy

- catalytic reaction

- ceramics

- electronic industries

- spectroscopy

Laboratory Hydraulic press is one high efficient equipment for the sample preparing, due to its small footprint, it easy to carry and move.

Laboratory Hydraulic press can work inside the vacuum glove box for processing under vacuum environment It is a versatile tool that can be used for a variety of tasks, from pressing samples to measuring pressures.

In the laboratory

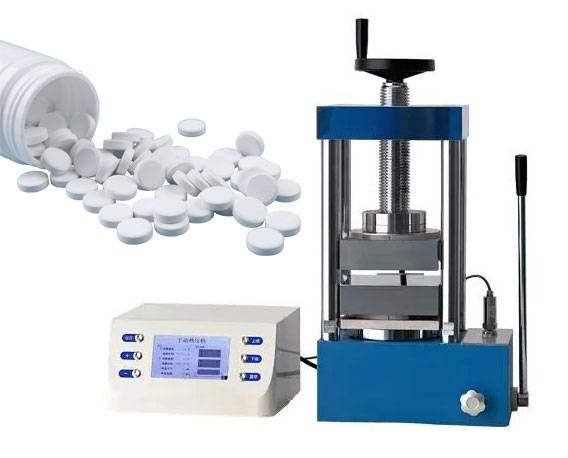

A laboratory press generally consists of a frame, a ram, and a baseplate, with the ram being driven by a hydraulic or pneumatic system. A laboratory press is a versatile tool that can be used in a variety of applications. In pharmaceutical development, for example, compressed pellets are used to create tablets. In spectroscopy, pellets are used to collect and study samples. And in ceramics, pellets are used to create detailed shapes and patterns.

Powders are placed into a die (or mold) of the laboratory press and are pressed into shape by hydraulic action. The laboratory press is a machine that uses a hydraulic system to generate a force that is transferred to the powder, which is then pressed into the desired shape.

The pellets produced by a laboratory press need to be of a consistent size and shape in order to be used in the intended application. The press can have a range of different pressures, depending on the material being pressed and the desired shape of the pellets.

Some laboratory presses come with the capability of accommodating a wide range of different-sized or customized dies. This can be a desirable feature for those who frequently need to change the size or shape of their products. It can also be helpful for those who want to experiment with different designs.

Some options for Laboratory Hydraulic press

Lab presses usually offer a handful of options with various ranges of temperature, pressure and platen sizes along with customization in order to meet particular processes.

Examples of some technical parameter options:

| Instrument model | PCH-24T1010 | PCH-30T2020 | PCH-60T1818 |

|---|---|---|---|

| Pressure Range | 0-24.0 tons | 0-30.0 tons | 0-60.0 tons |

| piston diameter | 95mm (d) in chrome plated oil cylinder | 110mm (d) in chrome plated oil cylinder | 150mm (d) in chrome plated oil cylinder |

| Main overall structure | Equipment without sealed connections to reduce oil leakage points | Equipment without sealed connections to reduce oil leakage points | Equipment without sealed connections to reduce oil leakage points |

| Mold heating temperature | Room temperature-300.0C/500.0C | Room temperature -300.0C/500.0C | Room temperature-300.0C/500.0C |

| Insulation method | Imported insulation board | Imported insulation board | Imported insulation board |

| Cooling method | Quick cooling with water cooling [optional water cooling machine] | Quick cooling with water cooling [optional water cooling machine] | Quick cooling with water cooling [optional water cooling machine] |

| Hot platen size | 100×100mm (M×N)with chamfer | 200×200mm(M×N) | 180×180mm (M×N) |

| Host size | 245×175×500mm(K×P×H) | 405×260×525mm(K×P×H) | 405 ×260×525mm(K×P×H) |

| Dimensions | 500×175×500mm(L×W×H) | 950×260×525mm(L×W×H) | 950×260×525mm(L×W×H) |

| power supply | 600 W(220V/110V can be customized) | 1200 W(220V/110V can be customized) | 1000 W(220V/110V can be customized) |

| Weight | 60 Kg | 180 Kg | 180 Kg |

Most laboratory press manufacturers design their products with low maintenance requirements, low noise levels, and a minimum use of space in mind. This allows for less disruptions in the workplace and a more efficient use of resources.

The main reason that scientists and researchers prefer these types of presses is because of their undeniable precision and their ability to meet rigorous demands. They are also said to be much easier to use than other types of presses, which is another big plus.

Laboratory presses are should also have a longer service life, providing consistent results over time. These presses can withstand the rigors of daily use in the lab, ensuring reliable operation for years to come.

Importance

Laboratory presses are versatile tools that can be used in a variety of industries. Pharmaceutical, laminating, and rubber and plastic molding are just a few of the industries that can benefit from the use of laboratory presses. Laboratory presses provide a controlled environment in which to test materials and prototypes before they are put into production. This allows for a higher degree of accuracy and quality control, which can save time and money in the long run.

Their abilities to withstand high temperatures and pressures allows for a consistent control over your research variables, which is especially important when your study requires a range of temperatures or pressures Operations within research come with high demands, which is exactly why laboratory presses are an integral part in industrial inquiries. Their abilities to withstand high temperatures and pressures allows for a consistent control over your research variables, which is especially important when your study requires a range of temperatures or pressures. By having this type of press within your laboratory, you can be sure that your research is as accurate as possible.

In industrial and commercial settings, heavy-duty testing and compaction machines are used to test and compact materials such as rubber, plastic, and laminate. These machines help ensure that these materials meet the required standards for strength and durability. Without these machines, it would be difficult to ensure the quality of these materials.

The design and manufacture of these presses typically includes programmable controls, allowing users to press products more accurately, consistently and according to specific requirements. By investing in a press with these capabilities, manufacturers can produce high-quality products while minimizing waste and maximizing efficiency.

How to choose laboratory press

Kindle Tech has compiled a list of the top five laboratory presses to make the decision easier. The first thing to consider is the size of the press. There are presses that range from small, manual presses to those that are large and automatic. The second thing to consider is the pressure that is needed for the job. There are presses that range from low pressure to high pressure. The third thing to consider is the type of material that will be pressed. There are presses that are designed for soft materials and those that are designed for hard materials. The fourth thing to consider is the speed at which the job needs to be done. There are presses that are designed for slow jobs and those that are designed for fast jobs. The fifth thing to consider is the safety features that are needed. There are presses that have safety features that are designed for specific jobs.

Knowing how much force is needed for a specific sample is critical when choosing a lab hydraulic press. If too much force is used, it can damage the sample. Not enough force will not provide an accurate reading.

Assuming that you are looking for information regarding how to choose an press for a laboratory: When choosing an press for a laboratory, it is necessary to consider how much space is provided in the lab, how much energy and strength is required to the press, and whether or not the press will have to move. Depending on the answer to these questions, different models of laboratory presses may be more or less appropriate. For example, a smaller laboratory press may be sufficient if space is limited, but a larger press may be necessary if the lab has a lot of space.

Related Products

- Manual Lab Heat Press

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

Related Articles

- Applications and Importance of Hydraulic Press in Laboratories

- Comprehensive Guide on Pellet Press Dies and Their Applications

- Understanding the Importance and Applications of Laboratory Presses

- Hydraulic Presses vs. Mechanical Presses Which is Right for Your Laboratory

- Automatic Hydraulic Press: The Ultimate Guide for Efficient Sample Preparation and Industrial Processes