The Concept and Inventor of Hydraulic Press

Table of Contents

Understanding hydraulic press

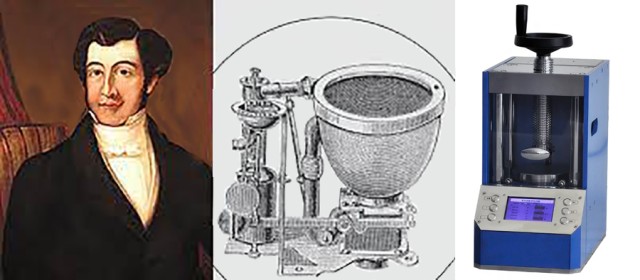

A hydraulic press, also known as a Bramah press, is a machine that uses fluid pressure to generate a force. This force can be used to compress or mold materials. Hydraulic presses are commonly used in manufacturing and industrial applications due to their ability to exert a large amount of force while still being easy to operate.

Laboratory hydraulic presses, on the other hand, are smaller and have a lower force capacity compared to industrial ones. However, they offer more precision, making them ideal for laboratory research and testing. For example, they are used in pressing KBr pellets for FTIR (Fourier transform infrared spectroscopy) or general sample pellets for XRF (X-ray fluorescence).

Introduction to Joseph Bramah, the inventor of hydraulic press

Joseph Bramah, the inventor of the hydraulic press, developed this technology in the 18th century. His invention revolutionized the manufacturing industry by providing a powerful and efficient method for compressing and molding materials.

The hydraulic press operates based on Pascal's Law, which states that the pressure in a confined fluid remains constant and is transmitted equally in all directions. This principle allows for the amplification of force through the use of fluid pressure.

Hydraulic presses have since become a vital tool in various industries, including metalworking, plastics processing, and woodworking. They are available in different sizes, capacities, and configurations to suit specific application requirements.

When purchasing a hydraulic press for a laboratory, it is essential to consider factors such as the desired force capacity, precision, and affordability. By understanding the concept and history behind the hydraulic press, you can make an informed decision when selecting the right machine for your laboratory application.

Pascal's Law and Hydraulic Principle

Definition and explanation of Pascal's Law

Pascal's Law states that the pressure exerted on a fluid is transmitted evenly throughout that fluid. In other words, any change in pressure applied to an enclosed fluid is transmitted undiminished to all parts of the fluid. This principle is based on the relationship between force, pressure, and area.

Pressure is defined as the quotient of the force acting perpendicularly on a surface and the area of that surface. It is represented by the equation P = F/A, where P is the pressure, F is the force, and A is the area. The SI unit of pressure is the pascal (Pa).

How hydraulic press applies Pascal's Law

A hydraulic press utilizes Pascal's Law to generate a compressive force. It consists of a cylinder with a piston inside and a pump that applies pressure to the oil or fluid inside the cylinder. When force is applied to a small area on the piston (F1), the hydraulic fluid transmits this force equally throughout, resulting in a larger force (F2) on a larger area.

The force generated by the hydraulic press is directly proportional to the area of the piston and the applied pressure. This allows for the amplification of force, making hydraulic presses capable of exerting tremendous amounts of pressure.

Hydraulic presses find various applications in different industries. In laboratories, they are commonly used to prepare samples for analysis. By compressing materials into pellets or thin films, a hydraulic press creates a homogenous sample suitable for spectroscopic examination.

One example of a hydraulic press is the KINTEK Manual Hydraulic Press, which operates based on the Bramah Press design. With this type of hydraulic press, the user applies pressure by hand, using a handle to pump pressure into the hydraulic fluid system. The resulting force can be as great as 25 tons.

By understanding Pascal's Law and the principles behind hydraulic presses, we can appreciate the power and versatility of these machines in various industries. Whether it's in laboratory settings or industrial applications, hydraulic presses play a crucial role in generating immense force for numerous tasks.

Applications of Hydraulic Press

General uses of hydraulic press

A hydraulic press is a machine that uses fluid pressure to generate a force. It is commonly used in manufacturing and industrial applications due to its ability to exert a large amount of force and its ease of operation. Laboratory hydraulic presses, which offer more precision and control, are used for research and testing purposes. They are commonly used to:

- Test the strength and durability of materials

- Investigate the effects of high pressure on different substances

- Create pellets for sample analysis

Hydraulic systems are efficient transmitters of power and can apply pressures in the region of 10,000 psi, compared to about 100 psi for pneumatic systems. Hydraulic presses have proven useful in a variety of applications, including straightening, bending, stamping, and flattening materials into desired shapes.

Specific application in preparing samples for spectroscopic examination

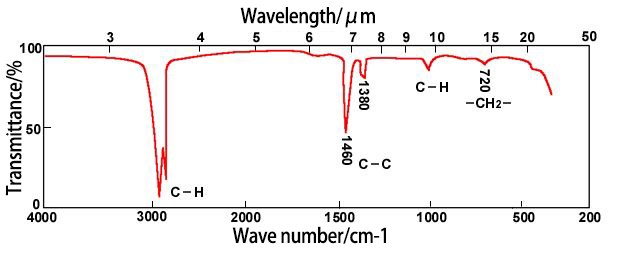

One of the most common uses of a laboratory hydraulic press is in sample preparation for spectroscopic examination. For example, in Fourier transform infrared spectroscopy (FTIR), a hydraulic press is essential for creating potassium bromide (KBr) pellets. These pellets are used to study the molecular structure of a powder sample by diluting it in a transparent material.

In X-ray fluorescence (XRF) spectroscopy, hydraulic presses are used to create general sample pellets for analysis. The process involves grinding the sample to a fine particle size, mixing it with a binder or grinding aid, pouring the mixture into a pressing die, and applying pressure to create a pellet. These pellets are then ready for analysis.

Use of KINTEK Manual Hydraulic Press

KINTEK manufactures manual hydraulic presses that are specifically designed for sample preparation in spectroscopic examinations. These presses are available in 8 and 60-tonne maximum load configurations and are ideal for FTIR, KBr, and XRF sample preparation.

The KINTEK manual hydraulic press features a sturdy frame, a lever arm for applying pressure, and a gauge for measuring force and pressure during sample preparation. It does not have any electronic components, making it a cost-effective option compared to automatic presses. However, it requires more physical effort to operate and may not offer the same level of repeatability as automatic presses.

Use in FTIR spectroscopy

FTIR spectroscopy is a type of spectroscopy that uses infrared light to study the properties of matter. In order to study the molecular structure of a powder sample, it first needs to be diluted in a transparent material. This is where a hydraulic press comes in.

By creating KBr pellets using a hydraulic press, the sample can be accurately and effectively analyzed using FTIR spectroscopy. The hydraulic press allows for the precise compression of the sample and KBr, ensuring a uniform distribution and a flat surface for accurate measurements.

Creating pellets using milled or finely ground samples

In various spectroscopic techniques, such as XRF analysis, creating pellets from milled or finely ground samples is a common practice. Hydraulic presses are used to compress the powdered samples into solid pellets for analysis.

The process involves placing the sample inside a pellet die and then using the hydraulic press to apply pressure and compress the sample into a pellet. This creates a uniform and consistent sample for accurate analysis.

Use in tension testing

Hydraulic presses are also used in tension testing, which involves pulling samples apart to measure their strength and durability. By gradually increasing the pressure from the hydraulic press, the capability of a material to resist shape deformations under pressure can be assessed. This type of testing is important in various industries, such as manufacturing and construction, to ensure the quality and reliability of materials.

Different Types of Hydraulic Presses

Overview of different types of hydraulic presses

Hydraulic presses are industrial machines that use fluid power to generate a compressive force for pressing, forging, and stamping various materials. They consist of a hydraulic cylinder powered by a pump and a bed or frame, which holds the die and the material to be pressed. Hydraulic presses are versatile and efficient machines that play a crucial role in many industrial processes, including metalworking, plastics processing, and woodworking. They can be used to perform operations such as forging, punching, blanking, deep drawing, and forming. Hydraulic presses are available in different sizes, capacities, and configurations, depending on the application's specific requirements. Some hydraulic presses have multiple cylinders and a complex control system, while others are simple, single-cylinder presses.

Details on manual hydraulic presses

A manual hydraulic press is a mechanical device that uses hydraulic pressure to crush or compress various materials. These presses are commonly used in laboratories to prepare samples for analysis, such as KBr pellets for FTIR spectroscopy or general sample pellets for XRF.

Manual hydraulic presses typically consist of a cylinder filled with hydraulic oil that supplies pressure to a moving piston. The pressure is applied using a hand-operated pump. The material to be compressed is placed on the piston, which is then slowly raised to apply a force to the material. Powder materials are usually contained in a pellet die, which causes the compressed powder to form a solid disc of material.

Manual hydraulic presses are available in a variety of sizes and capacities, so they can be used for both small-scale and large-scale testing.

Details on electric hydraulic presses

Electric hydraulic presses, on the other hand, are powered by an electric motor. They offer the advantage of automated operation, making them more convenient and efficient for certain applications.

Electric hydraulic presses can be equipped with LED touchscreens, allowing for easy operation and precise control of the pressing process. The touchscreens provide a user-friendly interface for setting the desired load and monitoring the progress of the press.

These presses can also be custom programmed to perform specific pressing cycles. This feature is particularly useful for ensuring consistency in sample preparation, as it allows for timer capability, auto top-up to maintain the desired load, and step function to gradually increase the load. Additionally, electric hydraulic presses can be designed to accommodate different power supply requirements, such as a standard mains plug/voltage or a 3-phase power supply.

Features of electric presses: with or without LED touchscreens and custom programmable loads

KINTEK offers two types of powered (electric) hydraulic presses: those with LED touchscreens and custom programmable loads, and those without. The presses with LED touchscreens provide a sleek design and an intuitive interface for easy operation. They offer the ability to program specific pressing cycles and monitor the progress of the press. On the other hand, the presses without LED touchscreens still provide the convenience and efficiency of automated operation but do not have the touchscreen interface.

These electric hydraulic presses are suitable for various applications, including industrial XRF applications, hot embossing, laminating, and melting polymers for thin films. They offer precise and consistent force for efficient sample preparation.

In conclusion, hydraulic presses are versatile machines that are widely used in various industries for pressing, forging, and stamping materials. Manual hydraulic presses are commonly used in laboratories for sample preparation, while electric hydraulic presses offer the convenience of automated operation and programmable loads. The availability of LED touchscreens and custom programmable loads further enhances their versatility and efficiency. Whether you need a manual or electric hydraulic press, there are options available to suit your specific requirements and applications.

If you are interested in this product you can browse our company website:https://kindle-tech.com/products/manual-lab-hydraulic-press-12t-15t-24t-30t-40t, we always insist on the principle of quality first. During the production process, we strictly control every step of the process, using high quality materials and advanced production technology to ensure the stability and durability of our products. to ensure that their performance meets the highest standards. We believe that only by providing customers with excellent quality can we win their trust and long-term cooperation.

Related Products

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Manual Lab Heat Press

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

Related Articles

- Manual Hydraulic Presses for Laboratory Use: A Comprehensive Guide

- A Comprehensive Guide on Pressing XRF Pellets Using a KinTek Automatic Hydraulic Press

- Automatic Hydraulic Press: The Ultimate Guide for Efficient Sample Preparation and Industrial Processes

- Comprehensive Guide to Manual Hydraulic Pellet Press

- Understanding the Functioning and Applications of a Hydraulic Pellet Press