Customer-made Press

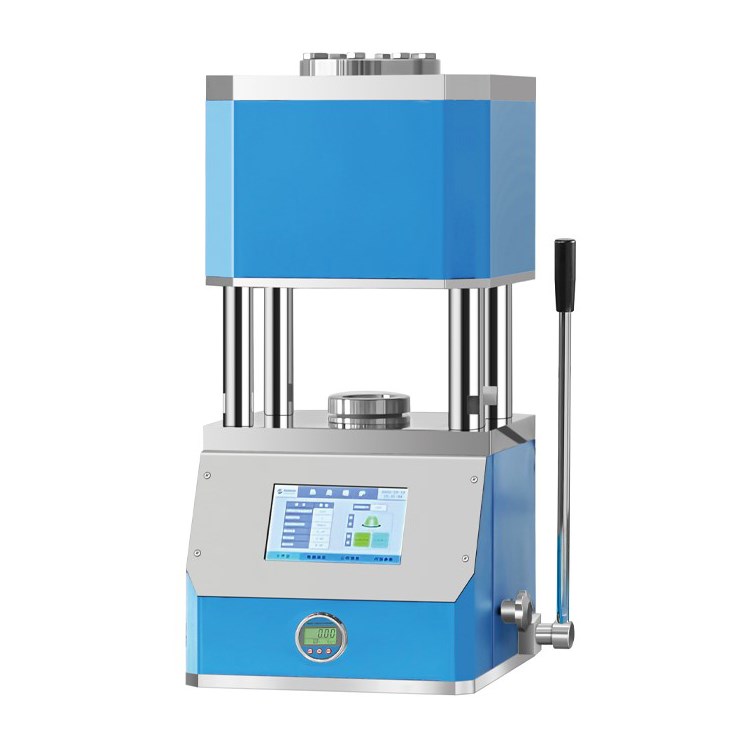

Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

Item Number : PCHT

Price varies based on specs and customizations

- Pressure process

- Manual pressurization

- Pressure holding time

- 1 second ~ ∞ seconds

- Cylinder stroke

- 80mm

- Heating temperature

- Maximum 1000℃

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Introduction

The High Temperature Hot Press is a machine specifically designed for pressing, sintering and processing materials in a high temperature environment. It is capable of operating in the range of hundreds of degrees Celsius to thousands of degrees Celsius for a variety of high temperature process requirements. Manual intervention is required to regulate and control pressure, temperature and other parameters during operation.

Applications

High temperature hot presses are widely used in the following areas:

High-temperature alloy manufacturing: used to manufacture aero-engine components, spacecraft materials, etc.

Powder metallurgy: used for manufacturing precision parts and metal products with complex structure.

Ceramic materials: used for sintering and processing of high temperature ceramics.

Electronic materials: for manufacturing semiconductor materials and magnetic materials.

Detail&part

- Step 1: Select the data screen and enter the setting interface

- Step 2: Select "Programmable segment setting"

- Step 3: There are 20 temperature rise control programs in the program, select the first segment

- Step 4: According to the experimental requirements, set the temperature and heating speed of the first segment

- Step 5: If multiple temperature rise programs are required, you can set the 20 segments

- Step 6: After setting, press the main interface to return to the operation interface

- Step 7: On the main interface, press "Heating Start".

- Step 8: The equipment starts to heat up according to the program.

- Step 9: The equipment stops automatically after heating. If the setting is wrong, such as the set temperature is not reached within the specified time, the equipment will automatically terminate.

Principle

High-temperature hot presses utilize the physical and chemical effects of high-temperature and high-pressure environments to press, sinter, and process materials by applying high pressure and temperature to the materials, prompting the rearrangement or crystallization of the material molecules. Under high temperature conditions, the material atoms can cross the energy barriers more easily, which is conducive to chemical reactions, grain growth and material densification, and thus improve the mechanical properties and heat resistance of the materials, as well as the manufacture of complex structural materials.

Feature

High-temperature operating capability: Capable of stable operation at extremely high temperatures, up to thousands of degrees Celsius.

Precise control: Equipped with precise temperature control and pressure control systems to ensure accurate and repeatable processing.

Adaptation to diverse materials: capable of handling various types of materials, including metals, ceramics, composites, etc.

High performance: equipment design and process optimization allow for high productivity and the ability to produce high quality products in large quantities.

Technical specifications

| Instrument model | PCHT |

|---|---|

| Pressure range | 0-5.0 tons |

| Pressure process | Manual pressurization |

| Pressure holding time | 1 second ~ ∞ seconds |

| Cylinder stroke | 80mm |

| Heating temperature | Maximum 1000℃ |

| Mold material | Nickel-based alloy (high temperature resistant material) |

| Sample size | Medium 10-30mm |

| Mold shape | Medium 50x90mm |

| Furnace diameter | Medium 60mm |

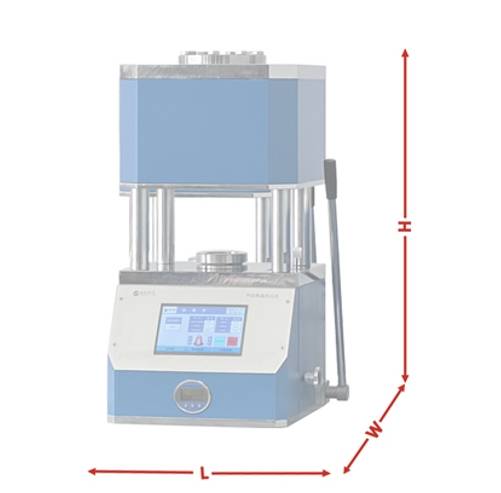

| Complete machine size | 400x380x780 (LxWxH) |

| Power supply | 220V 50Hz |

| Powder tablet press size diagram |  |

Operation steps

1.Place the sample into the mold.

2.Put the mold into the hot press.

3.Pre-press the sample.

4.Click on the data screen to set the heating temperature.

5.In the data screen, up to 20 heating programs can be set, and the heating speed can be adjusted.

6.Return to the main interface and start heating.

7.When the temperature reaches the set temperature, start pressurization.

8.Return to the main interface and start heating.

Trusted by Industry Leaders

FAQ

What Are The Advantages Of Using A Hydraulically Heated Laboratory Press?

What Is Mpcvd?

What Does A Hydraulic Lab Heat Press Do?

What Is Mpcvd Machine?

What Types Of Samples Or Materials Can Be Processed In A Hydraulically Heated Laboratory Press?

What Are The Advantages Of Mpcvd?

How Does A Hydraulically Heated Laboratory Press Work?

Are CVD Diamonds Real Or Fake?

How Can The Performance Of A Hydraulically Heated Laboratory Press Be Optimized?

4.7 / 5

Incredible precision and control, perfect for our lab's needs!

4.8 / 5

Fast delivery and top-notch quality, highly recommend!

4.9 / 5

Durable and reliable, a game-changer for our projects.

4.7 / 5

Value for money, exceptional performance and durability.

4.8 / 5

Technologically advanced, simplifies our complex processes.

4.9 / 5

Ergonomic design and user-friendly, a breeze to operate.

4.7 / 5

Highly satisfied with the speed and efficiency of this press.

4.8 / 5

Excellent build quality, stands up to rigorous lab use.

4.9 / 5

Innovative features make this a must-have for any lab.

4.7 / 5

Quick setup and easy operation, saves us time daily.

4.8 / 5

Robust and efficient, handles high-temp jobs flawlessly.

4.9 / 5

Outstanding customer service and product support.

4.7 / 5

Impressive durability, a key asset for our lab operations.

4.8 / 5

Highly precise, critical for our sensitive material experiments.

4.9 / 5

Exceptional value, enhances our lab's productivity significantly.

4.7 / 5

Reliable and consistent, a staple in our lab equipment.

4.8 / 5

Advanced technology at an affordable price, couldn't be happier.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

The Manual Heat Press is a versatile piece of equipment suitable for a variety of applications, operated by a manual hydraulic system that applies controlled pressure and heat to the material placed on the piston.

Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

The High Temperature Hot Press is a machine specifically designed for pressing, sintering and processing materials in a high temperature environment. It is capable of operating in the range of hundreds of degrees Celsius to thousands of degrees Celsius for a variety of high temperature process requirements.

24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

Looking for a reliable Hydraulic Heated Lab Press? Our 24T / 40T model is perfect for material research labs, pharmacy, ceramics, and more. With a small footprint and the ability to work inside a vacuum glove box, it's the efficient and versatile solution for your sample preparation needs.

Vacuum Hot Press Furnace Machine Heated Vacuum Press

Discover the advantages of Vacuum Hot Press Furnace! Manufacture dense refractory metals & compounds, ceramics, and composites under high temp and pressure.

Square Lab Press Mold for Laboratory Applications

Create uniform samples easily with Square Lab Press Mold - available in various sizes. Ideal for battery, cement, ceramics, and more. Custom sizes available.

Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

Get your exclusive CVD furnace with KT-CTF16 Customer Made Versatile Furnace. Customizable sliding, rotating, and tilting functions for precise reactions. Order now!

Square Bidirectional Pressure Mold for Lab Use

Discover precision in molding with our Square Bidirectional Pressure Mold. Ideal for creating diverse shapes and sizes, from squares to hexagons, under high pressure and uniform heating. Perfect for advanced material processing.

lab cryogenic grinding use liquid-nitrogen for pulverizing plastic raw materials and heat sensitive materials

Discover the KT-CG01 Liquid Nitrogen Cryogenic Pulverizer, Ideal for Plastic and Heat-Sensitive Material Pulverization, Preserving Material Integrity and Delivering Ultra-Fine Results.

Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

KT-PE12 Slide PECVD System: Wide power range, programmable temp control, fast heating/cooling with sliding system, MFC mass flow control & vacuum pump.

Lab Infrared Press Mold

Easily release samples from our lab infrared press mold for accurate testing. Ideal for battery, cement, ceramics, and other sample preparation research. Customizable sizes available.

Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

Learn about Cylindrical Resonator MPCVD Machine, the microwave plasma chemical vapor deposition method used for growing diamond gemstones and films in the jewelry and semi-conductor industries. Discover its cost-effective advantages over traditional HPHT methods.

Polygon Press Mold for Lab

Discover precision polygon press molds for sintering. Ideal for pentagon-shaped parts, our molds ensure uniform pressure and stability. Perfect for repeatable, high-quality production.

Related Articles

The War Against Voids: Mastering Material Density with Heat and Pressure

Hot pressing uses graphite tooling to apply extreme heat and pressure, eliminating microscopic voids to forge ultra-dense, high-performance materials.

High Pressure Tube Furnace: Applications, Safety, and Maintenance

Explore the advanced applications, safety measures, and maintenance tips for high pressure tube furnaces. Learn how these furnaces are used in various high-temperature processes and ensure optimal performance and safety.

Beyond Heat: Why Pressure is the Deciding Factor in Advanced Materials

Explore the critical trade-offs between hot pressing and sintering. Learn how pressure transforms material properties, costs, and project outcomes.

The Physics of Impossible Shapes: Why Hot Stamping Redefined High-Strength Steel

Hot stamping transforms steel at a molecular level, using a heat-and-quench cycle to forge ultra-strong, lightweight parts impossible with cold forming.

Forged Under Pressure: The Unseen Science of High-Durability Lab Surfaces

Discover how hot press lamination forges non-porous, chemical-resistant surfaces, making it the ideal foundation for modern laboratory furniture.

Understanding Hot Presses and Safety Considerations

An overview of hot presses, their applications, advantages, and safety precautions.

Principles and Applications of Vacuum Hot Press Sintering Equipment

Exploring the principles, classification, and applications of vacuum hot press sintering equipment in materials science.

The Pressure Paradox: Why More Isn't Always Better in Hot Press Sintering

Increasing pressure in hot press sintering speeds densification but risks hidden flaws like anisotropy. Mastering this trade-off is key to superior materials.

Operation of Vacuum Hot Press Sintering Furnace

An overview of the operation and components of a vacuum hot press sintering furnace, focusing on its application in the preparation of high-temperature wear-resistant ceramics.

Optimizing Laboratory Analysis with Split Automatic Heated Lab Pellet Press

Explore the advanced features and benefits of split automatic heated lab pellet presses for precise pellet preparation in various analytical applications. Ideal for high-throughput laboratories.

Advanced Ceramics Hot Press Sintering Technology and Equipment

Explores the hot press sintering process for advanced ceramics, its methods, advantages, equipment, and applications.

The Physics of Permanence: How Hot Presses Forge the Modern World

Hot presses use controlled heat and pressure to create permanent bonds. Discover how this transformative technology enables everything from electronics to advanced materials.