Molds & Accessories

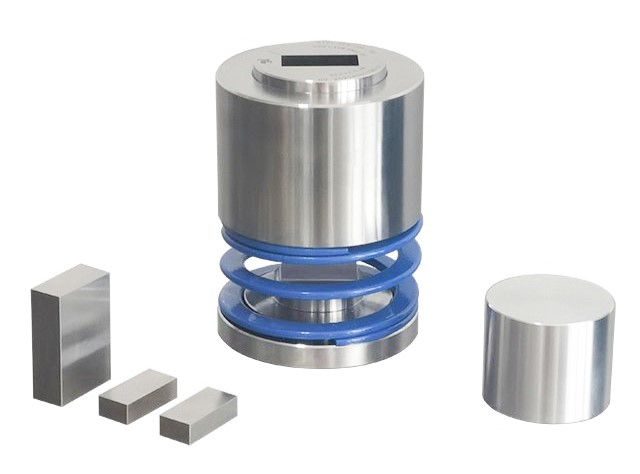

Square Bidirectional Pressure Mold for Lab Use

Item Number : PMS-F

Price varies based on specs and customizations

- Die material

- Alloy tool steel : Cr12MoV

- Indenter hardness

- HRC60-HRC62

- Sample size

- 12*12、15*15、18*18、20*20 mm(M)

- Cavity depth

- 40mm (N)

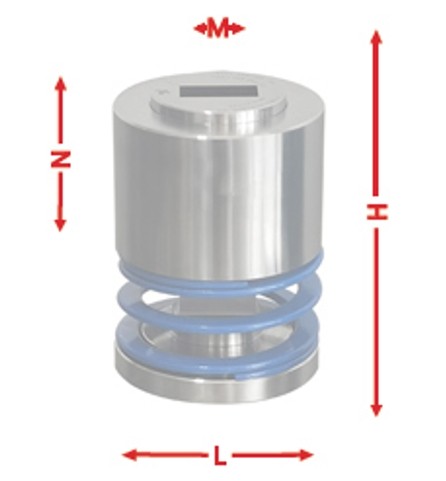

- Dimensions

- Φ88*175mm(L*H)

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Introduction

The Square Bidirectional Pressure Mold is a specialized hydraulic press designed for molding powders into various shapes with high precision and pressure. It accommodates different mold shapes, including round, square, and hexagonal, and features electric heating for controlled temperature during the molding process. This equipment leverages Pascal's principle to uniformly distribute pressure across the mold, ensuring consistent product quality. Ideal for applications requiring large cross-sectional areas or high pressure, it supports the production of diverse sizes and shapes of molded parts.

Applications

Square bidirectional pressure molds are versatile tools used in various industries for creating precise, high-quality molded parts. These molds are particularly beneficial for applications requiring high pressure and uniform distribution of force across the material being molded. Below are some of the main application areas where square bidirectional pressure molds are extensively used:

- Pharmaceutical Industry: Used for pressing tablets with specific shapes and sizes, ensuring uniform distribution of active pharmaceutical ingredients.

- Ceramics Manufacturing: Ideal for shaping ceramic powders into intricate designs under high pressure, leading to durable and precise ceramic products.

- Polymer Processing: Employed in the production of polymer films and sheets with various cross-sectional shapes, enhancing the functionality and aesthetic appeal of the final product.

- Metallurgy: Utilized in the pressing of metal powders into compact shapes, which are then sintered to create complex metal parts.

- Food Industry: Applied in the compression molding of food products like candies and chocolates, ensuring consistent shape and texture.

- Automotive Parts Manufacturing: Used for creating precise and durable automotive components such as gaskets and seals.

These applications highlight the versatility and importance of square bidirectional pressure molds in industries where precision, uniformity, and durability are paramount.

Detail & Parts

Technical specifications

| Instrument model | PMSY |

|---|---|

| Sample shape |  |

| Die material | Alloy tool steel : Cr12MoV |

| Indenter hardness | HRC60-HRC62 |

| Sample size | 12*12、15*15、18*18、20*20 mm(M) |

| Cavity depth | 40mm (N) |

| Dimensions | Φ88*175mm(L*H) |

| Weight | 3.0Kg |

| Diagram of hydraulic powder press size |  |

Operation steps

Two way pressurized cylindrical open mold is suitable for samples with high density requirements for powder pressing.

1.Assemble the die according to the operation diagram and install the sample in the cavity.

2.Assemble the die according to the operation diagram and install the sample in the cavity.

3.Assemble the die according to the release diagram ,eject the sample out of the die bushing with the screw rod.

4.Take out the die from the hydraulic press ,and remove the sample gently.

Trusted by Industry Leaders

FAQ

What Is A Press Mold?

What Is Press Mould In Ceramics?

How Are Pellet Molds Used?

What Types Of Materials Can Be Pelletized Using Pellet Molds?

How Can One Select The Appropriate Pellet Mold For Their Specific Application?

4.7 / 5

Incredible precision and durability. A game-changer for our lab!

4.8 / 5

Fast delivery and excellent value for money. Highly recommend!

4.9 / 5

Technologically advanced and user-friendly. Perfect for our needs!

4.7 / 5

Outstanding quality and performance. Best investment for our lab!

4.8 / 5

Efficient and reliable. Makes our work so much easier!

4.9 / 5

Top-notch technology and support. Couldn't be happier!

4.7 / 5

Superb durability and functionality. A must-have for any lab!

4.8 / 5

Quick setup and easy operation. Great value for the price!

4.9 / 5

Exceptional product quality. Streamlined our processes significantly!

4.7 / 5

Highly advanced and efficient. Boosted our lab's productivity!

4.8 / 5

Reliable and sturdy. Perfect for high-pressure applications!

4.9 / 5

Outstanding customer service and product support. Very satisfied!

4.7 / 5

Excellent build quality. Handles high pressures with ease!

4.8 / 5

Fast and efficient. Great for our pharmaceutical applications!

4.9 / 5

Highly precise and durable. A key asset for our lab!

4.7 / 5

Superb technology. Enhances our ceramic molding process!

4.8 / 5

Reliable and user-friendly. A great addition to our setup!

4.9 / 5

Exceptional performance. Highly recommend for any lab!

4.7 / 5

High-quality and efficient. Streamlined our polymer processing!

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Square Lab Press Mold for Laboratory Applications

Create uniform samples easily with Square Lab Press Mold - available in various sizes. Ideal for battery, cement, ceramics, and more. Custom sizes available.

XRF & KBR steel ring lab Powder Pellet Pressing Mold for FTIR

Produce perfect XRF samples with our steel ring lab powder pellet pressing mold. Fast tableting speed and customizable sizes for accurate molding every time.

XRF & KBR plastic ring lab Powder Pellet Pressing Mold for FTIR

Get precise XRF samples with our plastic ring lab powder pellet pressing mold. Fast tableting speed and customizable sizes for perfect molding every time.

Polygon Press Mold for Lab

Discover precision polygon press molds for sintering. Ideal for pentagon-shaped parts, our molds ensure uniform pressure and stability. Perfect for repeatable, high-quality production.

Lab Infrared Press Mold

Easily release samples from our lab infrared press mold for accurate testing. Ideal for battery, cement, ceramics, and other sample preparation research. Customizable sizes available.

Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

Get your exclusive CVD furnace with KT-CTF16 Customer Made Versatile Furnace. Customizable sliding, rotating, and tilting functions for precise reactions. Order now!

1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

Discover our KT-12A Pro Controlled atmosphere furnace - high precision, heavy duty vacuum chamber, versatile smart touch screen controller, and excellent temperature uniformity up to 1200C. Ideal for both laboratory and industrial application.

Glassy Carbon Electrochemical Electrode

Upgrade your experiments with our Glassy Carbon Electrode. Safe, durable, and customizable to fit your specific needs. Discover our complete models today.

Glassy Carbon Sheet RVC for Electrochemical Experiments

Discover our Glassy Carbon Sheet - RVC. Perfect for your experiments, this high-quality material will elevate your research to the next level.

Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

The High Temperature Hot Press is a machine specifically designed for pressing, sintering and processing materials in a high temperature environment. It is capable of operating in the range of hundreds of degrees Celsius to thousands of degrees Celsius for a variety of high temperature process requirements.

Related Articles

Comprehensive Guide to Metal Mold Pressing: Techniques, Equipment, and Applications

Explore the detailed process of metal mold pressing, including equipment, techniques, and applications. Learn how hydraulic presses shape materials like metal and rubber efficiently.

Comprehensive Guide to Cylindrical Lab Electric Heating Press Mold: Technology and Applications

Explore the advanced features and applications of cylindrical lab electric heating press molds. Learn about their working principles, types of heating technologies, and key benefits for precise sample preparation.

Nine Precision Molding Processes of Zirconia Ceramics

An overview of nine advanced molding processes for zirconia ceramics, including dry and wet methods.

Issues with Poor Demoulding in Manual Tablet Presses

Analyzes the causes of poor demoulding in manual tablet presses, focusing on powder, mold, machine body, and operator factors.

Precision Ceramic Injection Molding: Key Processes

An in-depth look at the stages of precision ceramic injection molding, focusing on grouting, holding pressure, cooling, and demolding.

Advanced Ceramics Hot Press Sintering Technology and Equipment

Explores the hot press sintering process for advanced ceramics, its methods, advantages, equipment, and applications.

Vacuum Hot Press Sintering Furnace Structure and Classification

An in-depth look at the structure, types, and components of vacuum hot press sintering furnaces, focusing on their applications and benefits in material densification.

Advanced Alumina Ceramics: Applications and Manufacturing Techniques

This article discusses the applications and manufacturing techniques of advanced alumina ceramics, including molds, isostatic pressing, and green bodies.

Defects and Solutions for Isostatically Pressed Ceramic Balls

This article discusses various defects in isostatically pressed ceramic balls and provides solution strategies for each type of defect.

Vacuum Heat Treatment: Principles and Processes

An overview of vacuum heat treatment methods to improve material properties.

The Architecture of Silence: Purity in the Five-Port Cell

Preventing contamination is not just about cleaning; it is about system management. Master the protocols for glass and PTFE to ensure electrochemical precision.

The Architecture of Control: Why Thermal Stability Defines Electrolysis Success

Discover how double-layer water-bath electrolytic cells eliminate thermal variables, ensuring accuracy and reproducibility in electrochemical research.