Introduction to Manual Hydraulic Sample Making Machine

Components and Functionality

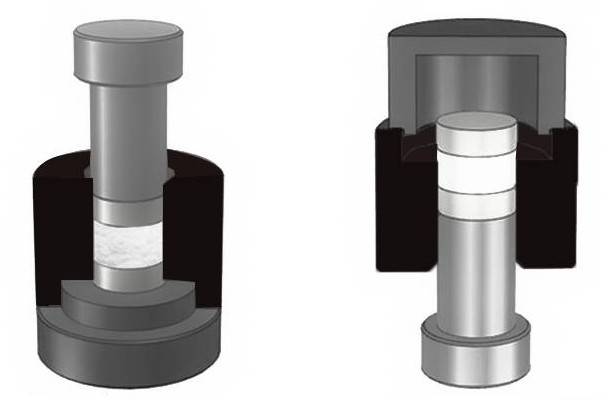

The manual hydraulic sample making machine is a sophisticated piece of equipment designed for precise sample preparation. It comprises several key components, each playing a crucial role in the sample-making process. The core component is the sample-making mold, which is composed of an upper punch, a middle die, a lower punch, and an ejector die. These elements work in unison to form and eject the sample accurately.

In addition to the mold, the machine features a hydraulic gauge that monitors and controls the pressure applied during the sample-making process. This ensures consistency and precision in the final product. The hand-cranked jack is another essential component, providing the mechanical force necessary to operate the hydraulic system. Lastly, the fuselage houses all these components, ensuring their alignment and secure operation.

Each of these components is meticulously designed and manufactured to withstand the rigors of the sample-making process, ensuring that the machine can produce high-quality samples reliably and efficiently.

Types of Molds

Molds in manual hydraulic sample making machines are categorized into different sets based on their design and functionality, primarily focusing on their ejection mechanisms. The most common types are four-piece sets and three-piece sets.

-

Four-Piece Sets: These molds consist of an upper punch, middle die, lower punch, and an ejector die. This comprehensive setup ensures precise control over the tablet-making process, facilitating smooth ejection and reducing the risk of jamming.

-

Three-Piece Sets: These molds are slightly more streamlined, comprising an upper punch, middle die, and lower punch. While they offer a more straightforward design, they are still effective for certain ejection methods, albeit with slightly less control compared to four-piece sets.

The choice between these types often depends on the specific requirements of the ejection process, balancing the need for precision with the simplicity of operation.

Analysis of Demoulding Issues

Powder Factors

Issues related to powder factors significantly influence the molding quality and can lead to mold jamming in manual tablet presses. Among these factors, moisture content plays a pivotal role. Excessive moisture can cause the powder to agglomerate, making it difficult to achieve uniform compaction and leading to inconsistent tablet hardness. Conversely, overly dry powders can result in poor binding properties, causing tablets to crumble or break apart easily.

Fineness of the powder is another critical parameter. Powders that are too coarse may not fill the mold cavities adequately, resulting in incomplete tablet formation or weak tablets. On the other hand, overly fine powders can create excessive friction during the compression process, leading to increased wear on the mold and potential jamming.

Cylinder pressure strength and bulk density are also key determinants of molding quality. Insufficient cylinder pressure can result in tablets that are too soft, while excessive pressure can cause the mold to deform or break. Bulk density, which refers to the mass of the powder per unit volume, influences the uniformity of the tablet. Inconsistent bulk density can lead to variations in tablet weight and hardness.

Lastly, fluidity of the powder affects the ease with which it flows into the mold cavities. Poor fluidity can cause uneven distribution of the powder, leading to non-uniform tablets and increased risk of mold jamming. Ensuring optimal fluidity through proper blending and conditioning is essential for efficient and reliable tablet production.

Mold Factors

The longevity and performance of a mold in a manual tablet press are significantly influenced by several key factors: material, design, processing, and maintenance. Each of these elements plays a crucial role in ensuring the mold's efficiency and durability.

Material Selection

The choice of mold material is paramount. High-quality materials, such as hardened steel, offer superior wear resistance and can withstand the high pressures and frequent use inherent in tablet pressing. Conversely, inferior materials can lead to premature wear and tear, compromising the mold's integrity and performance.

Design Considerations

A well-designed mold is essential for optimal performance. The design should account for the specific requirements of the tablet being produced, including size, shape, and the type of powder being compressed. Advanced design features, such as smooth internal surfaces and precise dimensions, can reduce friction and wear, thereby extending the mold's service life.

Processing Techniques

The manufacturing process of the mold is another critical factor. Precision machining and heat treatment are necessary to ensure the mold can withstand the mechanical stresses of the tablet pressing process. Any deviations in these processes can result in substandard molds that are prone to failure.

Maintenance Practices

Regular maintenance is indispensable for maintaining the mold's performance and longevity. This includes cleaning the mold after each use, inspecting for signs of wear, and promptly addressing any issues. Proper lubrication and storage practices can also prevent unnecessary wear and ensure the mold remains in optimal condition.

Machine Body Factors

Column alignment, beam processing, and installation quality are critical components that significantly influence the operational accuracy of manual tablet presses. These factors, often overlooked, can lead to a cascade of issues if not meticulously managed.

Column Alignment

Proper column alignment is essential for ensuring that the machine operates smoothly and accurately. Misaligned columns can cause uneven pressure distribution, leading to poor tablet quality and frequent mold jamming. The alignment process involves precise adjustments to ensure that all columns are perfectly parallel, which is crucial for maintaining consistent pressure across the mold.

Beam Processing

Beam processing quality directly impacts the machine's ability to apply uniform pressure. A poorly processed beam can result in uneven compression, causing tablets to vary in density and hardness. This variability not only affects the quality of the tablets but also increases the likelihood of mold damage due to uneven stress distribution. High-quality beam processing ensures that the beam is both strong and flexible, capable of withstanding the pressures required for effective tablet compression.

Installation Quality

Installation quality is another pivotal factor that determines the machine's operational accuracy. A poorly installed machine can lead to misalignment of components, causing operational inefficiencies and potential safety hazards. Proper installation involves not only the physical placement of the machine but also the calibration of all components to ensure they function optimally. This includes checking for any potential interferences and ensuring that all moving parts are properly lubricated and adjusted.

Operator Factors

Proper operation, maintenance, and handling are pivotal in preventing mold jamming and ensuring safety during the operation of manual tablet presses. Operators must be thoroughly trained in the correct procedures to handle the equipment effectively. This includes understanding the specific requirements for loading and unloading molds, as well as the appropriate settings for hydraulic pressure and other operational parameters.

Maintenance routines are equally critical. Regular checks and timely replacements of worn-out components can significantly extend the lifespan of the machine and reduce the likelihood of unexpected failures. Operators should be familiar with the maintenance schedule and capable of performing basic upkeep tasks, such as lubricating moving parts and inspecting for signs of wear.

Handling techniques also play a vital role. Improper handling of the molds, such as dropping or exposing them to extreme temperatures, can lead to damage and subsequent jamming issues. Operators must be trained to handle the molds with care, ensuring they are stored and transported properly.

By adhering to these guidelines, operators can contribute to a safer and more efficient operation of manual tablet presses, minimizing the risk of mold jamming and other related issues.

Related Products

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Multi-Punch Rotary Tablet Press Mold Ring for Rotating Oval and Square Molds

- Single Punch Manual Tablet Press Machine TDP Tablet Punching Machine

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Ring Press Mold for Lab Applications

Related Articles

- How to choose a laboratory hot press

- Automatic flat plate heat press operating steps

- Automatic Hydraulic Press: The Ultimate Guide for Efficient Sample Preparation and Industrial Processes

- Operating of Automatic Lab xrf Pellet Press

- Fully automatic tablet press operating steps and replacement accessories