Tablet punching machine

Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

Item Number : TPM-01

Price varies based on specs and customizations

- Pressure

- 60KN

- Capacity

- 9000pcs/h

- Motor power

- 2.2Kw

- Weight

- 320kg

- Dimension

- 960*660*1230mm

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Application

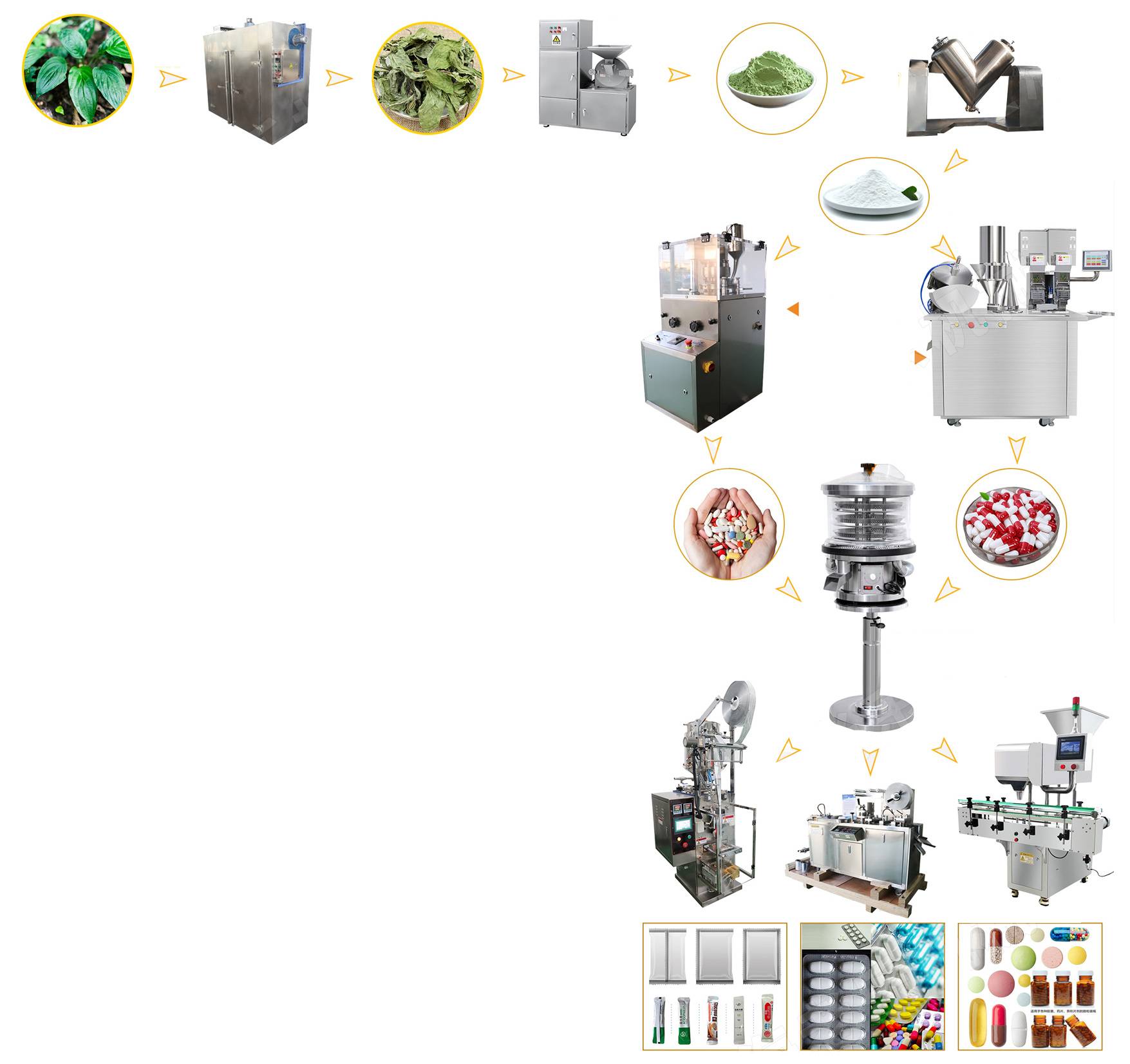

This machine is a single-pressure automatic rotating, continuous tableting machine that compresses granular raw materials into various tablets. It is mainly used for tablet production in the pharmaceutical industry, and is also suitable for chemical, food, electronics and other industrial sectors.

Feature

The outer shell is fully enclosed, made of stainless steel, and the internal table is made of stainless steel. The surface of the turntable has been specially treated to maintain surface gloss and prevent cross-contamination, complying with GMP requirements. The doors and windows equipped with transparent glass can clearly observe the status of the tableting, and can be fully opened, making it easy to clean and maintain the interior. All controls and operating parts are well laid out. The frequency conversion speed regulating device is used for electrical speed regulation, which is easy to operate, stable in rotation, safe and accurate. All transmission devices are arranged inside the machine to keep the machine parts clean. Equipped with an overload protection device, which can automatically shut down when the pressure is overloaded.

Detail & Parts

Technical specifications![Electric tablet punching machine details]()

![Electric tablet punching machine details]()

![Electric tablet punching machine details]()

![Electric tablet punching machine details]()

![Electric tablet punching machine details]()

Technical specifications

| Die quantity | 5 pcs |

| Pressure | 60KN |

| Max. Tablet diameter | 18mm |

| Max. Tablet height | 6mm |

| Max. Filling height | 15mm |

| Disc rotate speed | 30rpm |

| Capacity | 9000pcs/h |

| Motor power | 2.2Kw |

| Dimension | 960*660*1230mm |

| Weight | 320kg |

| 1. Excess powders can be recycled by a vacuum cleaner(Optional) | |

| 2. Tablet die can customized according to specific requirement | |

Trusted by Industry Leaders

FAQ

What Is A Tablet Punching Machine?

What Is A Lab Press?

What Is The Primary Function Of The Electric Tablet Punching Machine?

What Industries Primarily Utilize The Electric Tablet Punching Machine?

What Type Of Speed Regulating Device Does The Punching Machine Utilize, And What Are Its Advantages?

What Are The Main Types Of Tablet Punching Machines?

What Is The Purpose Of A Hydraulic Press In Lab?

What Is A Crushing Machine?

What Is The Principle Of A Tablet Punching Machine?

What Are Different Type Of Lab Presses?

What Factors Should Be Considered When Selecting A Crushing Machine?

What Are The Applications Of Tablet Punching Machines?

What Are The Advantages Of Using A Tablet Punching Machine?

How Does A Manual Tablet Press Work?

What Industries Benefit From Using Tablet Punching Machines?

What Safety Features Are Included In Tablet Punching Machines?

Why Has The Tablet Press Evolved Over Time?

5.0 / 5

The machine is very easy to use and maintain. It is also very durable and has been working flawlessly for over a year now.

4.9 / 5

I am very impressed with the quality of the machine. It is very well-made and has all the features I need.

4.8 / 5

The machine is very efficient and has helped me to increase my productivity significantly.

4.7 / 5

The machine is very affordable and has a great value for money.

4.6 / 5

The machine is very fast and has helped me to reduce my production time.

5.0 / 5

I am very happy with the machine and would definitely recommend it to others.

4.9 / 5

The machine is very easy to operate and has a user-friendly interface.

4.8 / 5

The machine is very durable and has a long lifespan.

4.7 / 5

The machine is very technologically advanced and has all the latest features.

4.6 / 5

I am very satisfied with the machine and would definitely buy it again.

5.0 / 5

The machine is very efficient and has helped me to save a lot of time and money.

4.9 / 5

I am very impressed with the quality of the machine and would definitely recommend it to others.

4.8 / 5

The machine is very easy to use and has a great value for money.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Single Punch Electric Tablet Press Machine TDP Tablet Punching Machine

The electric tablet punching machine is a laboratory equipment designed for pressing various granular and powdery raw materials into discs and other geometric shapes. It is commonly used in pharmaceutical, healthcare products, food, and other industries for small batch production and processing. The machine is compact, lightweight, and easy to operate, making it suitable for use in clinics, schools, laboratories, and research units.

Single Punch Manual Tablet Press Machine TDP Tablet Punching Machine

Single punch manual tablet punching machine can press various granular, crystal or powdery raw materials with good fluidity into disc-shaped, cylindrical, spherical, convex, concave and other various geometric shapes (such as square, triangle, ellipse, capsule shape, etc.), and can also press products with text and patterns.

Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

Controlled environment lab press machine for glove box. Specialized equipment for material pressing and shaping with high precision digital pressure gauge.

Rubber Vulcanizer Vulcanizing Machine Plate Vulcanizing Press for Lab

The Plate vulcanizing press is a kind of equipment used in the production of rubber products, mainly used for the vulcanization of rubber products. Vulcanization is a key step in rubber processing.

Multi-Punch Rotary Tablet Press Mold Ring for Rotating Oval and Square Molds

The multi-punch rotary tablet press mold stands as a pivotal component in pharmaceutical and manufacturing industries, revolutionizing the process of tablet production. This intricate mold system comprises multiple punches and dies arranged in a circular fashion, facilitating rapid and efficient tablet formation.

Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

Hydraulic diaphragm lab press filter is one type lab scale filter press, it takes small footprint, and higher pressing power.

Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

Introducing our inclined rotary PECVD furnace for precise thin film deposition. Enjoy automatic matching source, PID programmable temperature control, and high accuracy MFC mass flowmeter control. Built-in safety features for peace of mind.

Assemble Lab Cylindrical Press Mold

Get reliable and precise molding with Assemble Lab Cylindrical Press Mold. Perfect for ultra-fine powder or delicate samples, widely used in material research and development.

Laboratory Planetary Ball Mill Cabinet Planetary Ball Milling Machine

The vertical cabinet structure combined with ergonomic design enables users to obtain the best comfortable experience in standing operation. The maximum processing capacity is 2000ml, and the speed is 1200 revolutions per minute.

Isostatic Molding Pressing Molds for Lab

Explore high-performance isostatic pressing molds for advanced material processing. Ideal for achieving uniform density and strength in manufacturing.

Infrared Heating Quantitative Flat Plate Press Mold

Discover advanced infrared heating solutions with high-density insulation and precise PID control for uniform thermal performance in various applications.

Lab Vibration Mill

Vibration Mill for Efficient Sample Preparation, Suitable for Crushing and Grinding a Variety of Materials with Analytical Precision. Supports Dry / Wet / Cryogenic Grinding and Vacuum/Inert Gas Protection.

Related Articles

Innovative tableting solutions: a comprehensive analysis of laboratory single punch tablet presses

Discover the working principle of lab single punch tablet press and its advantages. Learn how it operates and its role in research and development. Find out the differences between single punch and rotary tablet presses.

Lab Scale Mini Tablet Press: Applications, Processes, and Features

Laboratory scale small tablet presses are versatile and essential tools for the pharmaceutical and related industries. It plays a vital role in producing simple yet precise tablets from powders, making it an integral part of research and development.

Fully automatic tablet press operating steps and replacement accessories

Relevant introduction to the operating steps and replacement accessories of the fully automatic tablet press

In-depth Analysis of Tablet Press Machine R&D Lab Model (1)

The Tablet Press Machine R&D Model, also known as a single punch tablet press, is designed for the development and small batch production of tablets. It is widely used in industries such as pharmacy, chemical, food, and metallurgy. This machine operates automatically, continuously filling, pressing, and ejecting tablets. Its key features include high precision filling, low noise, low material consumption, and smooth operation. It is particularly useful for research and development in laboratories, hospitals, and plants, catering to small-scale production needs.

Understanding the Tablet Press Machine R&D Lab Model and its Features(2)

The Tablet Press Machine R&D Model, also known as a single punch tablet press, is designed for the development and small batch production of tablets. It is widely used in industries such as pharmacy, chemical, food, and metallurgy. This machine operates automatically, continuously filling, pressing, and ejecting tablets. Its key features include high precision filling, low noise, low material consumption, and smooth operation. It is particularly useful for research and development in laboratories, hospitals, and plants, catering to small-scale production needs.

The working process of the tablet press you should know

What is tablet press and the working process of tablet press.

Tips With ADJUST THE PRESSURE OF THE LAB PRESS

When designing a pressure test, the required pressure is generally determined based on the material being tested. For example, softer materials may require less pressure than harder materials. The amount of pressure required will also depend on the specific test being performed.

Classification of tablet press molds and precautions for use

During the stamping process.A stamping die is a tablet press die that compresses a sample or tablet during the stamping process. The stamping die is placed on top of the tablet press and the sample is placed on top of the die. The die is then compression molded to the desired shape and size. here are some classification of tablet press molds and precautions for use.

Detailed Analysis of Tablet Presses: Their Types, Components, and Applications

Tablet presses are machines designed to compress pharmaceutical powders and granules into tablets. They play a crucial role in the pharmaceutical industry by ensuring the uniformity of each dosage unit, which is essential for patient safety. The precision capabilities offered by modern tablet presses are invaluable for pharmaceutical companies, as they help create tablets that contain the same amount of active pharmaceutical ingredients and excipients.

Manual tablet press operating steps and precautions

Details on the operation of manual tablet presses, replacement of rubber rings, and steps for replacement of parts.

Hydraulic Tablet Press: Comprehensive Guide to Design, Operation, and Applications

Explore the advanced features, operational principles, and diverse applications of hydraulic tablet presses in various industries. Learn how these machines ensure high-quality tablet production with detailed insights.

Sample preparation and unloading method of electric tablet press

How to prepare and unloading the sample? When tablet pressing, the operator must set the parameters of pressure, speed, and time according to the process requirements, so that the formed tablets meet the requirements for strength, hardness, and weight.