When designing a pressure test, the required pressure is generally determined based on the material being tested. For example, softer materials may require less pressure than harder materials. The amount of pressure required will also depend on the specific test being performed.

When storing and transporting tablets, it is important to preserve them and maintain a certain disintegration time limit. The pressure of the dose during tableting will also affect the actual thickness and appearance of the tablet. If the tablet is not stored or transported properly, it may disintegrate and become ineffective.

Pressure regulation

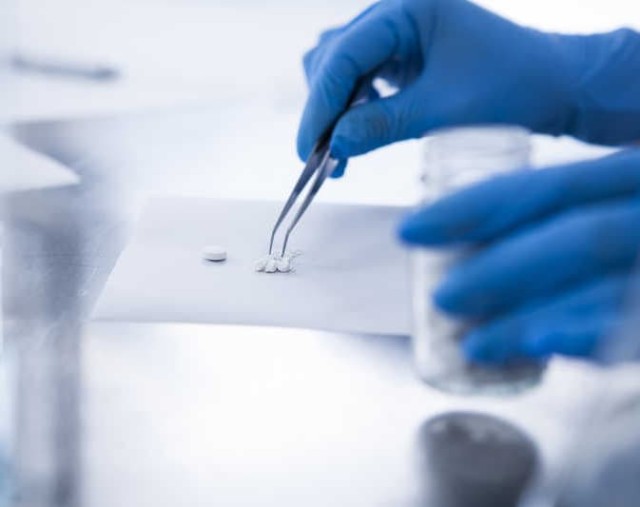

Pressure regulation is essential when compressing tablets in a laboratory press.

The pressure adjustment is achieved by adjusting the downward amount of the punch in the die hole. This is done by turning the pressure knob at the side of the machine. It is important to note that the die must be removed from the machine before the pressure can be adjusted.

Lab tablet presses are a specialized type of tablet press that not only have the upward and downward movements of the upper and lower punches during the tableting process, but also have the upper and lower movements of the lower punches, and the relative movement of the upper and lower punches completes the tableting process. These presses are designed for use in a laboratory setting and are often used to test the viability of a tablet formulation before it is scaled up for production.

The pressure adjustment method and pressure adjustment of the test tablet may affect the hardness of the tablet, which is also a reference for whether the tablet press can provide normal pressure for this product. It is necessary to measure the rms value of the pressure.

The lubrication of the machine is also a very important aspect that affects the pressure of lab press. In the initial operation stage, detect and observe whether there is insufficient lubrication and lack of grease and mechanical oil during the operation of the machine. If you find that there is no oil or less grease, you should stop the machine and add the appropriate amount of grease or oil. Lubrication plays an important role in machine operation because it can help to protect the machine from wear and tear, and it can also help to keep the machine running smoothly.

In the tablet press, the filling amount is an important factor to determine the accuracy of the unit amount of fill. It is necessary to accurately determine the amount of fill, otherwise it will affect the calculation of the amount of tableting. The amount of fill can be affected by the type of powder, the compressibility of the powder, and how much the powder is tamped.

Related Products

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T