What is tablet press

A tablet press is a machine that presses granular or powdery materials into tablets by a punch in the die hole. Tablet presses come in a variety of sizes and shapes, from small, hand-operated models to large, floor-mounted models.

Working process

Earlier tablet presses consisted of a pair of punching dies, with the punch moving up and down to press granular materials into tablets. This was called a single-punch tablet press. Later, this design was developed into an electric flower basket tablet press.

There are two main types of tablet presses: rotary and single-station. Rotary tablet presses have upper and lower punches that rotate in synchronization, while single-station tablet presses have a fixed lower punch and a moving upper punch. The working principle of these two types of tablet presses is still based on the one-way pressing of tablets by hand, i.e. the lower punch is fixed when pressing tablets, and only the upper punch moves and presses. This way of tablet pressing, due to the inconsistent force on the top and bottom, causes uneven density inside the tablet, and is easy to produce lobes and other problems.

The rotary multi-stroke bi-directional tablet press is a tablet press that is able to press pills in two directions. This allows for a more even distribution of the active ingredient in the pill and a better flow of materials through the machine. This tablet press is also able to handle higher loads and can produce more pills in a shorter amount of time.

This tablet press is ideal for high-density drugs that require a uniform density. The upper and lower strokes are pressed evenly at the same time, so that the air in the drug particles has ample time to escape from the mold holes. This improves the uniformity of the density of the tablets and reduces the phenomenon of lobes.

The rotary tablet press uses a rotating die to compress the powder and force it into the desired shape. The rotary tablet press has many advantages over other tablet pressing machines, including low vibration, low noise, low energy consumption, high efficiency, and accurate tablet weight.

The shape of the tablets

The tablet shape pressed by the tablet press is mostly oblate at first, and later developed into a shallow arc shape and a deep arc shape on the upper and lower sides, which is for the needs of coating.

The development of shaped tablet presses led to the production of oval, triangular, oblong, square, rhombus and circular tablets. These tablet presses allow for more precision in the manufacturing process, and also offer the potential for more interesting and visually appealing tablet shapes. This can be beneficial for both patients and pharmacists, as it can help to make tablets easier to identify and to remember to take.

Tablet presses are special machines that are used to form tablets from powders or granules. In addition to the requirements of compounding and time-release preparations, tablet presses can also be used to make double-layer, three-layer, and core tablets.

The working process of tablet press can be divided into the following steps.

- the punch part of the lower punch (whose working position is facing upward) is extended into the middle die hole from the lower end of the hole to seal the bottom of the hole.

- filling the middle die hole with the drug using the filler.

- the punch part of the upper punch (whose working position is facing downward) falls into the middle die hole from the upper end of the middle die hole and travels downward for a certain stroke to press the drug powder into tablets

- The upper punch lifts out of the hole. The lower punch rises to lift the tablet out of the middle die hole, completing a tablet pressing process.

- The lower punch descends to the original position and prepares for the next filling.

Related Products

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Single Punch Manual Tablet Press Machine TDP Tablet Punching Machine

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

Related Articles

- Detailed Analysis of Tablet Presses: Their Types, Components, and Applications

- Classification of tablet press molds and precautions for use

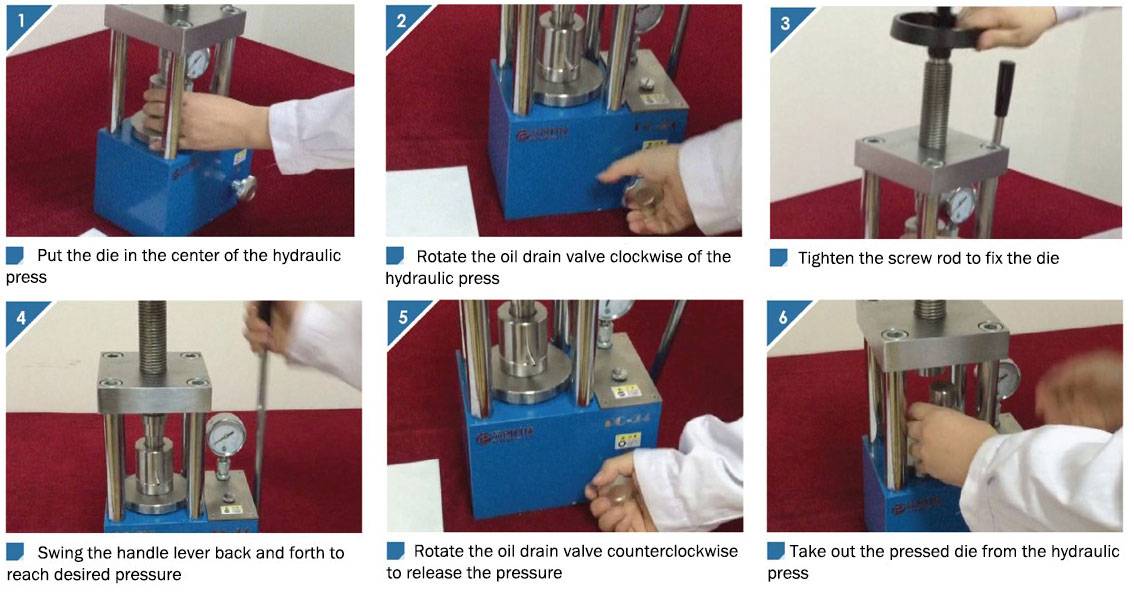

- Tips With ADJUST THE PRESSURE OF THE LAB PRESS

- Manual tablet press operating steps and precautions

- Fully automatic tablet press operating steps and replacement accessories