Vacuum Heat Treatment Processes

Vacuum Annealing and Normalizing

Vacuum annealing and normalizing are crucial processes in the treatment of hot-worked carbon steel blanks, each tailored to specific carbon content requirements. Vacuum annealing is primarily applied to steels with a carbon content exceeding 0.5%, aiming to reduce their hardness, thereby facilitating easier cutting operations. This process is conducted under vacuum conditions, which not only minimizes oxidation but also produces a high-quality surface finish, often referred to as "bright annealing." The controlled heating and slow cooling enhance the grain structure, making the material more uniform and better prepared for subsequent vacuum heat treatments.

In contrast, normalizing is utilized for steels with carbon content below 0.5%. This method involves heating the material to a higher temperature than annealing, followed by air cooling. The elevated temperature significantly affects the crystal structure, evening out the carbon distribution within the steel. This process is particularly beneficial for shaping and cold-forming operations, where the crystal structure can become distorted. By normalizing, the material's structure is refined, ensuring it remains sufficiently hard to avoid issues like low hardness and sticky cutting, which can complicate further machining processes.

Both vacuum annealing and normalizing play pivotal roles in refining the grain structure and achieving a uniform material composition, thereby preparing the steel for advanced vacuum heat treatments. These processes are not merely preparatory steps but integral to ensuring the final product's mechanical properties meet stringent quality standards.

Aging

Aging is a crucial step in the vacuum heat treatment process, primarily employed to mitigate internal stresses that accumulate during the manufacturing and machining of blanks. These stresses can compromise the precision and integrity of the final parts, making stress relief an essential pre-finishing procedure for components that demand high accuracy.

By subjecting the material to controlled thermal conditions, aging allows for the redistribution of these internal stresses, thereby enhancing dimensional stability and reducing the likelihood of future deformation. This process is often repeated to achieve optimal stress relief, ensuring that the material is in the best possible condition before undergoing further precision machining or assembly.

In essence, aging not only prepares the material for subsequent vacuum heat treatments but also plays a vital role in maintaining the structural integrity and performance of high-precision parts.

Tempering

Tempering is a critical step in the vacuum heat treatment process, typically conducted after high-temperature vacuum quenching. This procedure aims to achieve a uniform and fine vacuum tempering Sohnite organization, which significantly reduces the likelihood of deformation during subsequent treatments such as surface vacuum quenching and nitriding. The tempering process not only refines the microstructure but also enhances the mechanical properties of the material, making it more resilient and durable.

For parts that require moderate hardness and abrasion resistance, tempering can serve as the final vacuum heat treatment. This final step ensures that the material meets the necessary performance criteria without the need for additional treatments. By carefully controlling the tempering parameters, manufacturers can optimize the balance between hardness and toughness, ensuring that the parts are both strong and flexible, capable of withstanding various operational stresses.

In summary, tempering plays a pivotal role in the vacuum heat treatment sequence, offering a versatile solution for materials that need to strike a balance between hardness and durability.

Vacuum Heat Treatment Techniques

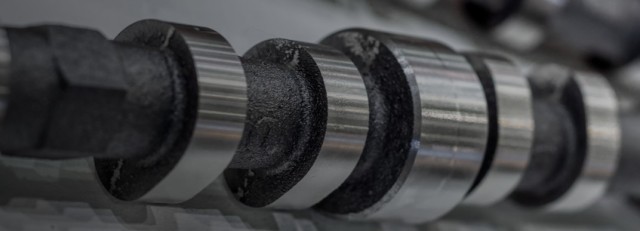

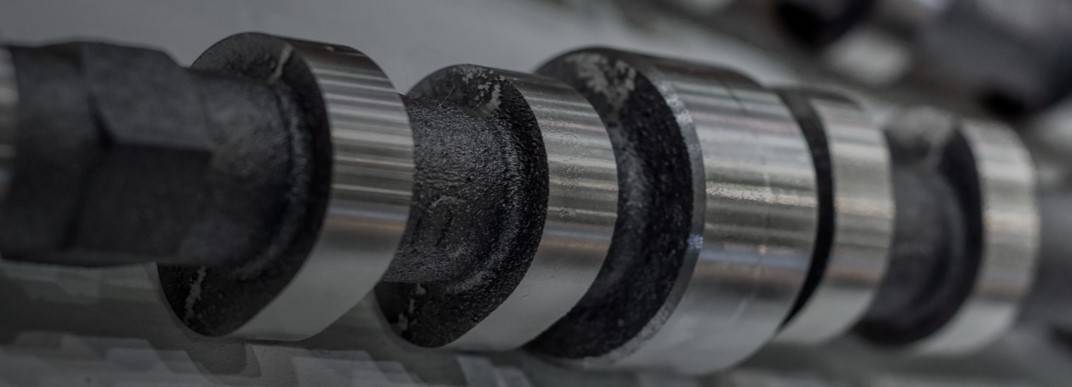

Vacuum Quenching

Vacuum quenching encompasses both surface and overall quenching methods, with surface vacuum quenching being the more prevalent due to its advantages in minimizing deformation and oxidation. This technique involves heating the material in a vacuum purge furnace, where the controlled atmosphere, typically a mixture of hydrogenated nitrogen and pure nitrogen, ensures that the part remains free from atmospheric interactions. The material is heated to a critical phase change temperature, which varies depending on the desired outcome of the quenching process. After reaching the required temperature, the material is held for a period sufficient to allow the transformation of the entire heated mass.

Following this, the material is rapidly cooled at a rate that effectively traps the chemical elements that have diffused at high temperatures. This rapid cooling induces stresses within the crystalline structure, which in turn enhances certain mechanical properties of the hardened part. One of the most significant benefits of vacuum quenching is that the treated parts do not oxidize, maintaining their original shiny appearance. This process not only improves the external strength and wear resistance of the material but also preserves its internal toughness and impact resistance, making it an ideal choice for applications where both durability and aesthetic appeal are critical.

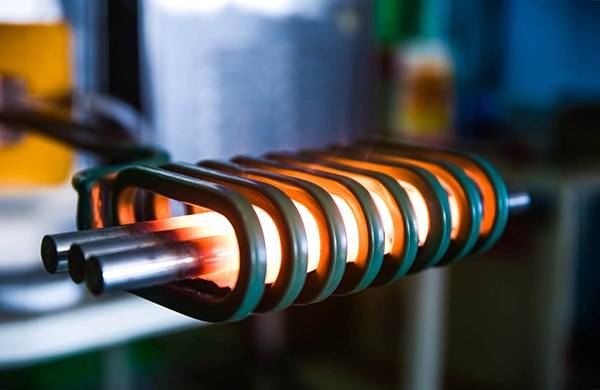

Vacuum Carburizing Quenching

Vacuum carburizing quenching is an advanced thermo-chemical treatment designed for low carbon and low alloy steels, offering a superior alternative to traditional atmospheric carburizing methods. This process involves heating steel parts to temperatures typically ranging from 900-1000°C within a vacuum environment, where carbon is introduced to penetrate the surface layer. This enrichment of carbon significantly increases the surface hardness, providing enhanced abrasion resistance, while simultaneously preserving the core's strength and toughness.

One of the key advantages of vacuum carburizing is its precision and control. The process allows for full automation, utilizing computer simulations to fine-tune heat treatment cycles, ensuring consistent results. This level of control is particularly beneficial for achieving the necessary dimensional tolerances, as evidenced by the high-pressure gas quenching method used in vacuum carburizing, which is showcased in Fig 4.

Moreover, vacuum carburizing is environmentally friendly, emitting no CO2, and operates without the risks associated with open flames or atmospheric gas chemistry. This makes it a clean, safe, and efficient process that is easy to integrate into manufacturing workflows. The absence of external influences such as gas chemistry or surface contaminants ensures that the carburizing process is pure, allowing for a uniform and predictable outcome.

In contrast to traditional carburizing, vacuum carburizing offers the flexibility to operate at higher temperatures and with more adaptable cycles, thanks to the unique characteristics of vacuum furnaces. This adaptability is crucial for meeting the diverse requirements of modern manufacturing, where parts often need to balance high surface hardness with core strength and toughness.

Vacuum carburizing quenching is typically applied between semi-finishing and finishing processes, serving as a critical step in the manufacturing pipeline. By enhancing the surface properties of the steel, it prepares the material for subsequent treatments, ensuring that the final product meets the stringent demands of high-performance applications.

Vacuum Nitriding

Vacuum nitriding is a sophisticated surface treatment process where nitrogen atoms are introduced into the metal surface to form a nitride layer. This layer significantly enhances the metal's properties, including surface hardness, wear resistance, fatigue strength, and corrosion resistance. Unlike traditional nitriding methods, vacuum nitriding is conducted at relatively low temperatures, typically ranging from 520 to 560℃, which helps to minimize thermal deformation and ensures that the metal's internal structure remains intact.

The process begins with the workpiece being placed into a vacuum furnace. The furnace is then evacuated to a pressure of approximately 0.1Pa, creating an environment where the temperature can be precisely controlled. Once the desired nitriding temperature is reached, the workpiece is held at this temperature for a duration that varies depending on the number of pieces being treated and the specific requirements of the process. This initial period is crucial for purifying the surface of the workpiece and preparing it for the nitrogen infusion.

Following this, the vacuum is temporarily halted, and nitrogen gas, often in the form of ammonia, is introduced into the furnace. The pressure within the furnace is raised to between 50 and 70Pa, maintaining this pressure for a short interval before reducing it again to between 5 and 10Pa. This cycle of "inflation-extraction" is repeated multiple times to ensure that the nitrogen atoms penetrate the metal surface uniformly, forming a robust nitride layer that meets the desired specifications.

One of the key advantages of vacuum nitriding is its ability to improve the fatigue strength and overall service life of treated parts. By eliminating the need for quenching, which is common in other heat treatment processes, vacuum nitriding significantly reduces the risk of distortion and warping in the treated components. This makes it an ideal choice for applications where maintaining dimensional accuracy is critical, such as in high-precision machinery and aerospace components.

In summary, vacuum nitriding is a highly effective method for enhancing the surface properties of metals without compromising their structural integrity. Its low-temperature operation and precise control over the nitrogen infusion process make it a preferred choice for industries requiring durable, high-performance components.

Related Products

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

Related Articles

- Manual Lab Hydraulic Pellet Press: Comprehensive Guide to High-Quality Pellet Preparation

- Understanding Hot Presses and Safety Considerations

- From Dust to Density: The Microstructural Science of Hot Pressing

- Operation of Vacuum Hot Press Sintering Furnace

- The Physics of Permanence: How Hot Presses Forge the Modern World