The Unseen Force of Transformation

Most engineered systems fight a constant battle against entropy. Connections loosen, materials delaminate, and components fail. It is the natural tendency of things to fall apart.

To counter this, we don't just need to join materials; we need to fundamentally transform them. We need to create bonds so intimate and robust that they act as a single, unified entity.

This is the quiet, essential work of the hot press. It is not merely a machine, but an instrument for imposing order and permanence, leveraging two of the universe's most fundamental forces: heat and pressure.

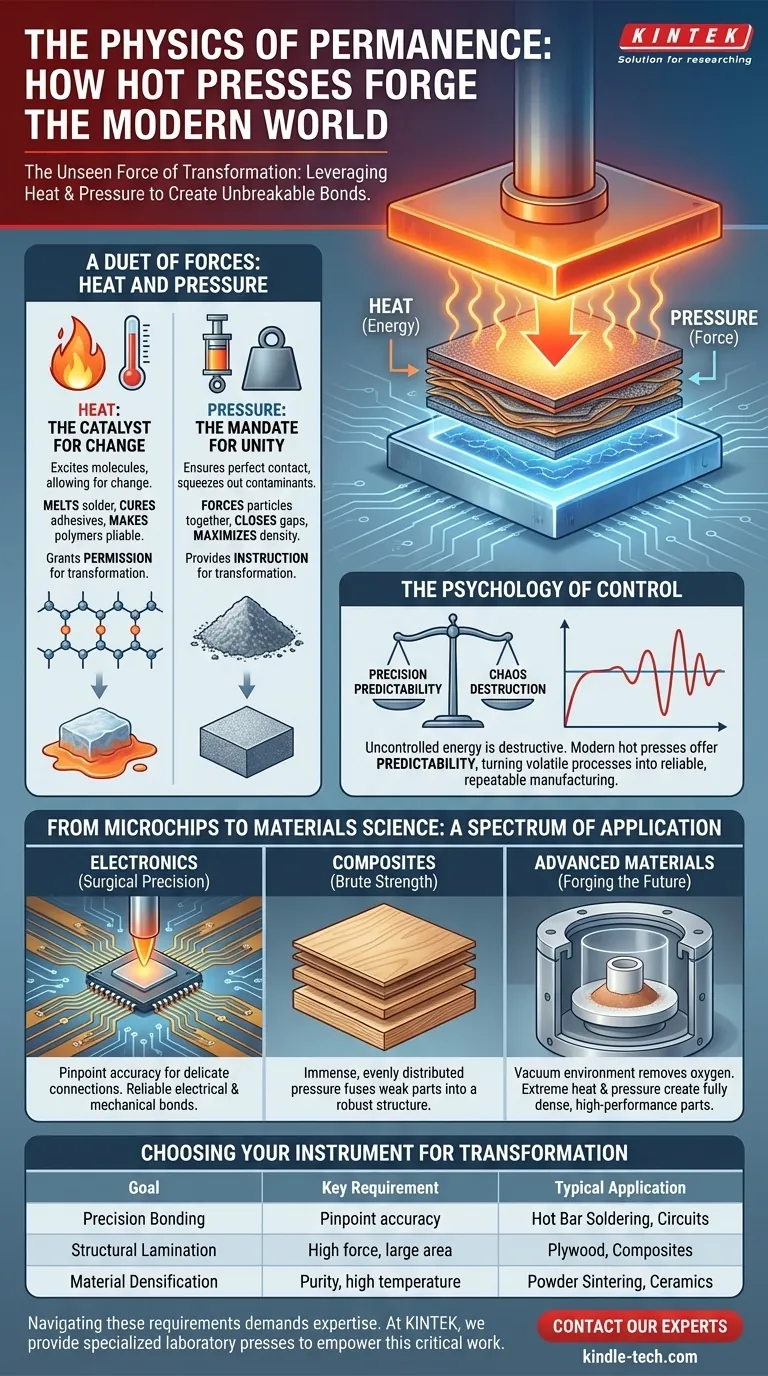

A Duet of Forces: Heat and Pressure

A hot press operates on a principle of elegant simplicity. By precisely orchestrating heat and force, engineers can achieve outcomes that are impossible with either one alone. It's a controlled, physical dialogue that convinces materials to become something new.

Heat: The Catalyst for Change

Heat is energy. When introduced into a material, it excites molecules, allowing for change.

It can melt a solder to an ideal fluid state, cure a thermosetting adhesive to create an unbreakable cross-linked structure, or make a dense polymer pliable enough to be reshaped. Heat grants the permission for transformation.

Pressure: The Mandate for Unity

Pressure is focused intent. It ensures that surfaces make perfect, intimate contact, squeezing out air, moisture, and other contaminants that are the enemies of a strong bond.

In processes like sintering, pressure forces loose powders together, closing the gaps between particles until the material approaches its theoretical maximum density. Pressure provides the instruction for transformation.

The Psychology of Control

Why is precision so critical? Because uncontrolled energy is destructive. Too much heat can degrade a material; too much pressure can crush it. The genius of a modern hot press lies in its predictability.

By removing chance from the equation, it gives engineers and scientists the confidence to build reliable, repeatable systems. It turns a volatile process into a stable, dependable manufacturing method.

From Microchips to Materials Science: A Spectrum of Application

The same core principles are applied across vastly different scales to solve unique engineering challenges.

The Surgical Precision of Electronics

Imagine trying to connect a hair-thin flexible circuit to a dense printed circuit board. A traditional soldering iron is a clumsy, imprecise tool for such a delicate operation.

A hot press, equipped with a perfectly flat titanium indenter, performs this task with surgical precision. It delivers a controlled pulse of heat and a measured force, creating hundreds of reliable electrical and mechanical bonds simultaneously. It is a feat of micro-manufacturing.

The Brute Strength of Composites

A single veneer of wood is fragile. But by stacking dozens of them, each coated in a thermosetting adhesive, and placing them in a large-platen hot press, something new is created.

The machine applies immense, evenly distributed pressure and sustained heat. This cures the adhesive and fuses the layers into a single, incredibly strong sheet of plywood. It transforms a collection of weak parts into a robust, structural whole.

Forging the Future with Advanced Materials

Consider a component for a jet engine or a high-performance ceramic tool. It must be created from a specialized powder and be free of even microscopic voids.

This is the domain of the vacuum hot press. By performing the process in a vacuum, it removes oxygen that would cause oxidation and compromise the material's integrity. The simultaneous application of extreme heat and pressure forces the powder particles to bond, creating a solid, fully dense part with properties unattainable through other means. This is the alchemy of modern materials science.

Choosing Your Instrument for Transformation

Selecting a hot press isn't about buying a piece of equipment; it's about defining the transformation you need to achieve. The goal dictates the design.

| Goal | Key Requirement | Typical Application |

|---|---|---|

| Precision Bonding | Pinpoint accuracy | Hot Bar Soldering, Circuits |

| Structural Lamination | High force, large area | Plywood, Composites |

| Material Densification | Purity, high temperature | Powder Sintering, Ceramics |

Navigating these requirements demands expertise. Whether you're assembling delicate electronics, producing industrial composites, or pioneering new materials in a laboratory setting, the quality of your equipment determines the quality of your results. At KINTEK, we provide the specialized laboratory presses and consumables that empower this critical work.

Creating something that lasts is a fundamental engineering pursuit. The hot press is a powerful tool in this endeavor, providing the controlled environment where simple components are forged into a strong, reliable, and permanent new form.

For help selecting the right equipment to achieve your specific transformation, Contact Our Experts.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

Related Articles

- The Physics of Impossible Shapes: Why Hot Stamping Redefined High-Strength Steel

- Comprehensive Guide to Vacuum Hot Press Furnace Application

- Beyond Heat: Why Pressure is the Deciding Factor in Advanced Materials

- Vacuum Hot Press Furnace: A Comprehensive Guide

- The Physics of Perfection: Why a Vacuum Is the Material Scientist's Most Powerful Tool