An aerospace engineer stares at a design for a new turbine blade. It must withstand hellish temperatures and unimaginable stress. A biomedical researcher holds a blueprint for a ceramic hip implant; it needs to be flawlessly smooth and biocompatible, with zero chance of failure.

In both worlds, the goal is the same: to transform a simple powder into a solid object of near-perfect density.

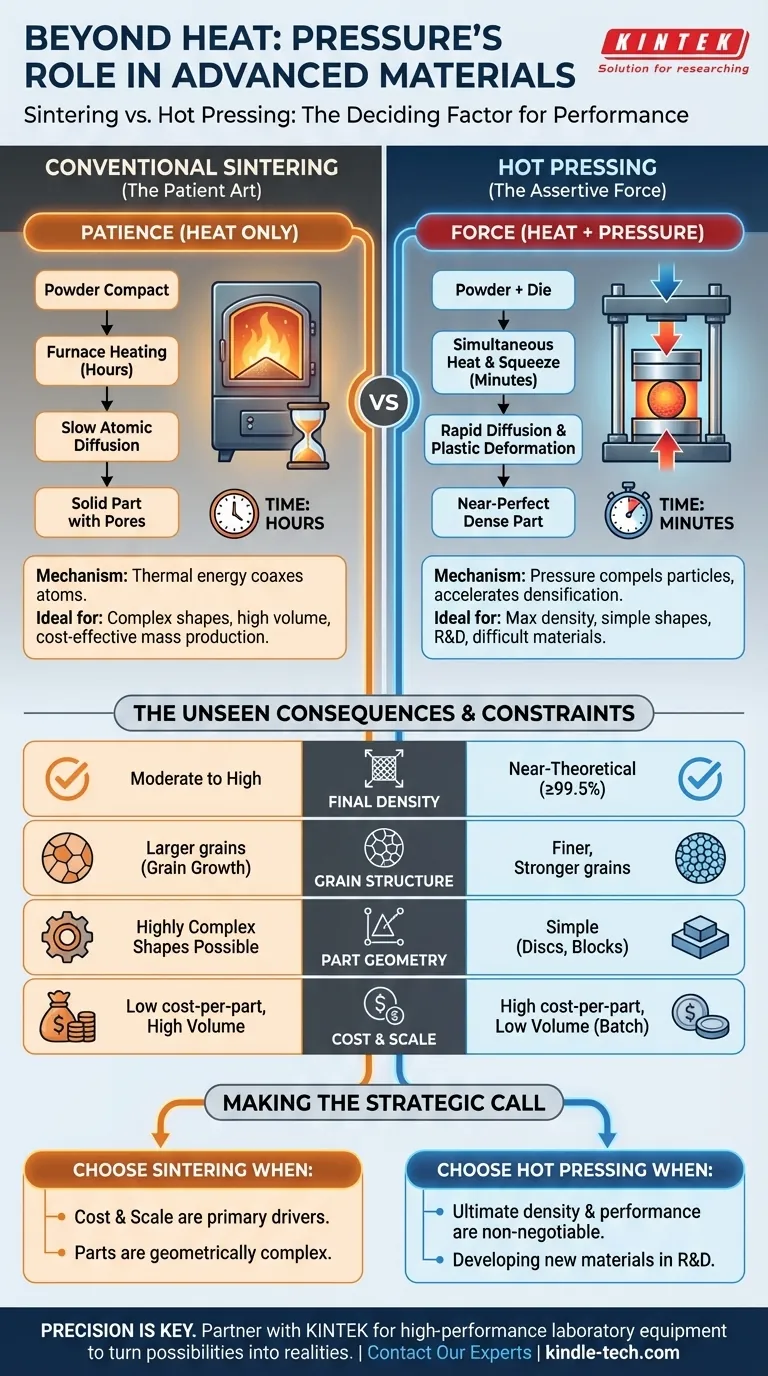

The path to that perfection, however, forces a fundamental choice. It's a decision that pits patience against force, cost against performance, and complexity against scale. This is the choice between conventional sintering and hot pressing.

The Core Conflict: Patience vs. Force

At their heart, both processes use heat to convince individual grains of powder to join together, forming a solid mass. The philosophical and practical difference lies in a single variable: external pressure.

Conventional sintering is an act of patience. You gently compact a powder into a "green" part, place it in a furnace, and wait. Over hours, thermal energy coaxes atoms to migrate across grain boundaries, slowly closing the gaps between them. It’s an elegant process driven entirely by heat and time.

Hot pressing is an act of force. It takes that same powder, but instead of coaxing it, it compels it. The powder is heated and squeezed simultaneously under immense pressure. This combination doesn't just accelerate atomic diffusion; it physically deforms the particles, forcing them into any available void. It’s an activated, assertive process that achieves in minutes what sintering takes hours to do.

The Physics of Creation: Two Paths to a Solid

This fundamental difference—heat alone versus heat and pressure—creates two distinct pathways to densification, each with its own signature on the final material.

The Patient Art of Sintering

Sintering is the established workhorse of powder metallurgy and ceramics.

- Process: A pre-formed part is heated below its melting point.

- Mechanism: Atoms diffuse across particle boundaries, driven by thermal energy.

- Timeline: The process is slow, often requiring furnace cycles of several hours.

It relies on the material's innate willingness to bond when heated. Its effectiveness is a function of temperature, time, and the initial packing of the powder.

The Assertive Force of Hot Pressing

Hot pressing is the specialist's tool, used when the absolute best properties are required.

- Process: Powder is heated and compacted in a single step inside a die.

- Mechanism: A combination of accelerated atomic diffusion and physical plastic deformation.

- Timeline: Exceptionally fast, with densification often complete in 3-10 minutes.

The applied pressure is a catalyst, dramatically lowering the time and sometimes even the temperature needed to achieve a fully dense state.

The Unseen Consequences of a Choice

The decision to use pressure is not merely about speed. It fundamentally alters the microstructure and performance of the final component.

The Pursuit of Perfection: Density

Hot pressing consistently achieves higher final densities—often approaching 100% of the material's theoretical density. The pressure is ruthlessly efficient at eliminating the final, stubborn pores that can remain after conventional sintering. This translates directly to superior mechanical properties like strength and hardness.

The Architecture of Strength: Grain Growth

Because hot pressing works at lower temperatures and for much shorter durations, it limits grain growth. A finer grain structure is often a stronger, tougher one. This makes it indispensable for high-performance ceramics like silicon carbide and silicon nitride, which are notoriously difficult to densify without their grains growing uncontrollably.

The Reality of Constraints: Cost, Scale, and Shape

If hot pressing yields superior results, why isn't it used for everything? Because performance exists in a world of practical and economic constraints. The choice is often less about what is technically best and more about what is practically feasible.

| Feature | Hot Pressing | Conventional Sintering |

|---|---|---|

| Primary Driver | Heat & High Pressure | Heat Only |

| Final Density | Near-Theoretical (≥99.5%) | Moderate to High |

| Part Geometry | Simple (discs, blocks) | Highly Complex Shapes Possible |

| Cost & Scale | High cost-per-part, low volume (batch process) | Low cost-per-part, high volume (mass production) |

| Ideal Application | R&D, maximum performance, hard-to-sinter materials | Cost-effective mass production, intricate components |

A Hot Press is a complex, expensive machine. The dies must be made of exotic materials like graphite to survive the punishing conditions. This makes the cost-per-part high. Furthermore, the uniaxial pressure limits production to simple shapes. You can't hot press a gear with intricate teeth.

Conventional sintering, especially when combined with methods like metal injection molding (MIM), excels at producing thousands of geometrically complex parts at a low cost-per-part.

Making the Call: A Framework for Your Goal

Ultimately, the choice is strategic. You must weigh the demands of your application against the realities of your budget and production scale.

- Choose Hot Pressing when: The absolute highest density and mechanical performance are non-negotiable. You are working with difficult-to-sinter materials or developing new ones in a lab setting where speed and quality trump cost.

- Choose Conventional Sintering when: You are manufacturing geometrically complex parts in high volumes, and cost-effectiveness is a primary driver.

Navigating these trade-offs requires not just knowledge, but the right laboratory tools. For researchers and engineers pushing the boundaries of material science, having access to high-performance equipment from a trusted provider like KINTEK is not a luxury—it is a necessity. The ability to control temperature and pressure with precision is what turns theoretical possibilities into physical realities.

If you are facing this critical decision for your material or application, the first step is understanding the capabilities of your equipment. Contact Our Experts

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Warm Isostatic Press for Solid State Battery Research

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

Related Articles

- Vacuum Hot Press Furnace: A Comprehensive Guide

- From Dust to Density: The Microstructural Science of Hot Pressing

- Comprehensive Guide to Vacuum Hot Press Furnace Application

- The Physics of Impossible Shapes: Why Hot Stamping Redefined High-Strength Steel

- The Unseen Physics of Perfection: Mastering Heat, Pressure, and Time