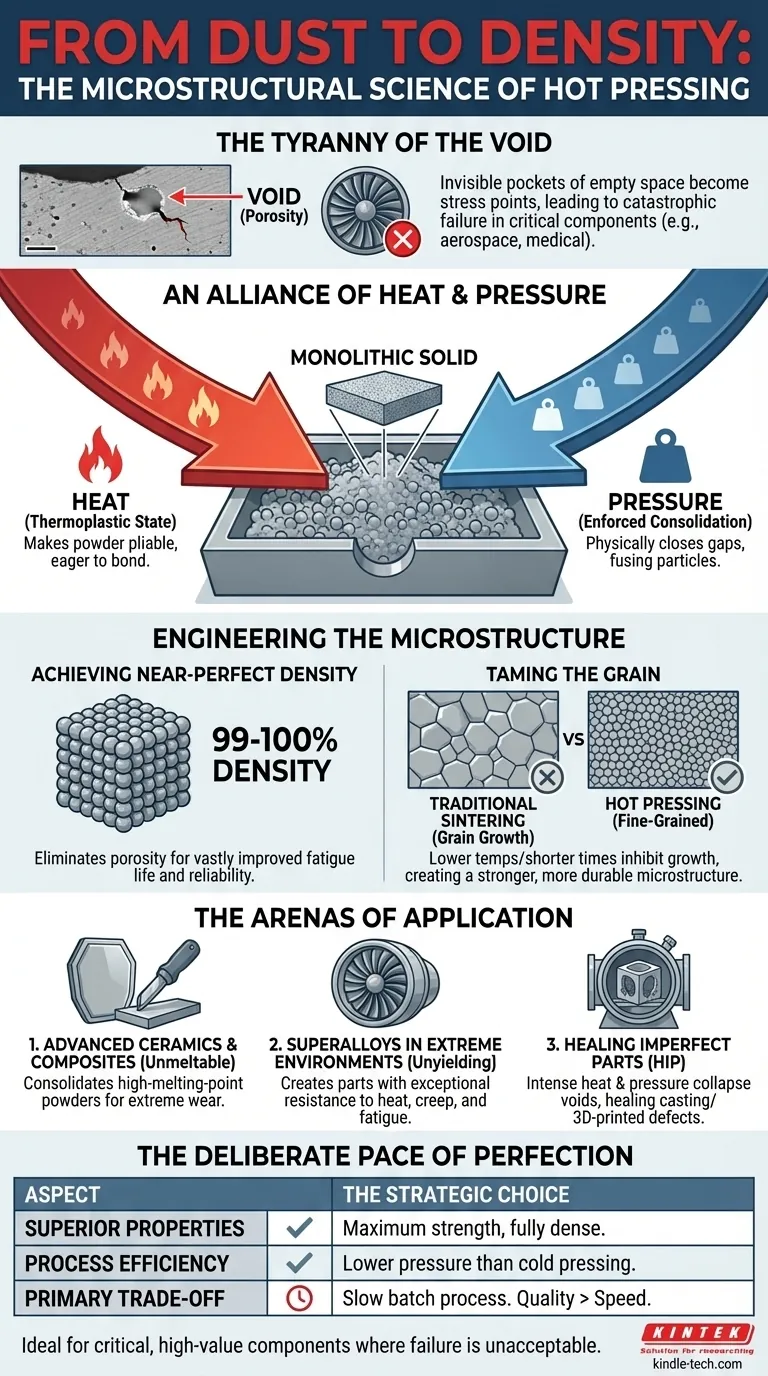

The Tyranny of the Void

Imagine a turbine blade inside a jet engine. It spins thousands of times per minute, enduring temperatures that would melt steel and forces that could tear a car apart. Its greatest enemy is not the visible stress, but the invisible one: a microscopic pocket of empty space, a void no larger than a grain of salt, trapped within the metal during its creation.

This tiny bubble of nothingness becomes a stress concentration point. Under extreme conditions, a crack begins here. The crack grows. The result is catastrophic failure.

This isn't just a problem for aerospace. In armor, cutting tools, and medical implants, the most profound engineering challenge is often the fight against internal voids. Porosity is the enemy of performance, an unpredictable flaw that undermines the integrity of an otherwise perfect design.

An Alliance of Heat and Pressure

How do you eliminate something that is, by definition, empty space? You can't machine it away. You must fundamentally re-engineer the material's internal structure. This is the purpose of hot pressing.

Unlike conventional manufacturing where a part is first pressed cold and then heated (sintered), hot pressing applies thermal and mechanical energy simultaneously.

The logic is simple but profound. Heat puts the material's constituent powders into a thermoplastic state, making them pliable and eager to bond. The pressure then becomes incredibly effective, physically closing the gaps between particles and forcing them to fuse into a single, monolithic solid.

It’s not merely forming a shape; it's a process of enforced consolidation at the granular level.

Engineering the Microstructure

The true elegance of hot pressing lies in the control it offers over the material's final, internal architecture. This control manifests in two critical ways.

Achieving Near-Perfect Density

The primary outcome is the systematic elimination of porosity. By squeezing the material while it's hot and soft, the process can achieve 99-100% of the material's theoretical maximum density.

That "1%" difference is everything. A part that is 99.9% dense doesn't just have 10% more strength than a part that is 90% dense; its fatigue life and resistance to failure can be orders of magnitude greater. It transforms the material from a reliable component into a near-perfect one.

Taming the Grain

Material strength is also dictated by its grain structure. Generally, smaller, more uniform grains lead to higher strength and hardness.

Traditional high-temperature sintering can cause grains to grow, weakening the final part. Because hot pressing is so efficient, it can be performed at lower temperatures and for shorter durations. This inhibits unwanted grain growth, resulting in a fine-grained microstructure that is inherently stronger and more durable.

The Arenas of Application

This pursuit of microstructural perfection means hot pressing is the chosen method when performance is non-negotiable.

1. The Unmeltable: Advanced Ceramics & Composites

Materials like silicon nitride or boron carbide have incredibly high melting points and cannot be cast like metals. Hot pressing is a primary method for consolidating their powders into fully dense forms for extreme applications, such as ceramic armor, high-speed cutting tools, and industrial wear components.

2. The Unyielding: Superalloys in Extreme Environments

The aerospace and energy sectors depend on superalloys for parts that must survive hellish conditions. Hot pressing and its variant, Hot Isostatic Pressing (HIP), consolidate superalloy powders into turbine blades and engine components with exceptional resistance to heat, creep, and fatigue.

3. The Second Chance: Healing Imperfect Parts

Perhaps one of the most powerful uses of the technology is to fix components made by other methods. A metal casting or a 3D-printed part can be subjected to a HIP cycle. The intense heat and pressure collapse any internal voids, healing the part from the inside out and dramatically increasing its reliability and service life.

The Deliberate Pace of Perfection

Choosing a manufacturing process is a psychological decision as much as an engineering one. It's a choice about what you value most. Hot pressing represents a commitment to certainty over speed.

| Aspect | The Strategic Choice |

|---|---|

| Superior Properties | The primary goal. Creates fully dense, fine-grained parts for maximum strength. |

| Process Efficiency | Lower pressure requirements than cold pressing can mean smaller equipment. |

| Primary Trade-Off | A slow batch process. You are trading high-volume output for ultimate quality. |

It is not the right tool for making millions of simple parts. It is the right tool for making a few critical parts perfectly. This makes it ideal for laboratory-scale development and the production of high-value, high-performance components where failure would be unacceptably costly.

The Choice for Certainty

Ultimately, the decision to use hot pressing is a decision to eliminate the hidden variable. It’s an acknowledgment that the greatest risks often lie in the microscopic imperfections we cannot see. By applying heat and pressure in concert, we can transform a loose collection of powder into a solid, void-free component engineered for absolute reliability.

At KINTEK, we provide the specialized lab equipment and hot pressing systems that empower researchers and engineers to achieve this level of material perfection. If your goal is to develop materials that push the boundaries of performance and reliability, you need tools designed for that specific purpose.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- Vacuum Hot Press Furnace Machine for Lamination and Heating

Related Articles

- The Physics of Perfection: Why a Vacuum Is the Material Scientist's Most Powerful Tool

- Beyond Heat: How Pressure Forges Near-Perfect Materials

- Molybdenum Vacuum Furnace: High-Temperature Sintering and Advanced Applications

- Vacuum Hot Press Furnace: A Comprehensive Guide

- Comprehensive Guide to Spark Plasma Sintering Furnaces: Applications, Features, and Benefits