Automatic Heated Lab Press

Automatic Laboratory Heat Press Machine

Item Number : PZAH

Price varies based on specs and customizations

- Heating temperature

- 300°C - 800°C

- Pressure range

- 0.01-5.0 tons to 0.01-60 tons

- Tablet size

- 120 x 120 mm to 500 x 500 mm

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Application

Automatic Laboratory Heat Press Machines serve as indispensable tools across diverse industries requiring precision material processing. In the automobile sector, they thermoform critical components like dashboards, door panels, and composite body parts, ensuring structural integrity while reducing weight. Laboratories leverage these machines for rigorous material testing—evaluating strength under extreme pressure, analyzing high-pressure effects on substances, and preparing standardized pellets for spectroscopy (FTIR, XRF). The technology also excels in:

- Composite Manufacturing: Crafting aerospace-grade carbon fiber panels and lightweight structural elements.

- Electronics: Laminating flexible circuits and bonding heat-sensitive components with micron-level accuracy.

- Research & Development: Simulating industrial processes for polymers, ceramics, and nanomaterials at controlled temperatures up to 800°C.

- Medical Device Fabrication: Sterilizing and molding biocompatible implants without compromising material properties.

With customizable workspaces (e.g., 120x120mm to 500x500mm) and programmable multi-step cycles, these machines adapt to prototyping and quality control workflows. Laboratories handling battery electrode compaction, graphene synthesis, or pharmaceutical tablet coating will find unmatched versatility in achieving repeatable results.

Feature

KINTEK’s Automatic Heat Press integrates cutting-edge engineering with user-centric design:

- Precision Control:

- PID-regulated temperature uniformity (±0.5°C deviation) across platen surfaces.

- Hydraulic pressure accuracy of 0.01 tons, scalable from 0.01-60 tons.

- Advanced Interface:

- 7-inch IPS HD touchscreen for real-time monitoring of pressure/temperature graphs.

- USB data export for Excel-based process analytics and compliance documentation.

- Safety & Durability:

- Acrylic doors with auto-shutdown sensors + emergency stop buttons.

- Silver-plated electrical contacts rated for >100,000 cycles.

- Programmable Workflows:

- 18-step sequences with independent pressure/temperature/cooling profiles.

- Adjustable ramp rates for controlled material transitions.

- Thermal Management:

- Dual-zone heating/cooling platens and water-assisted rapid cooling.

- Power options up to 16KW for 500°C operations.

Robust construction features SKD alloy pressing plates and double-laminated guide columns, minimizing deformation during high-load tasks. Remote control via PC enables batch processing and data comparison—ideal for ISO-certified environments.

Advantage

KINTEK’s solution outperforms conventional presses by merging efficiency with scientific rigor:

- Cost Reduction:

- Automation slashes labor by 70%, with energy-efficient heaters lowering power consumption.

- Minimal material waste due to 0.01-ton pressure increments.

- Enhanced Productivity:

- 18-program memory enables unattended batch processing overnight.

- Rapid cooling cuts cycle times by 40% versus passive systems.

- Uncompromised Quality:

- Aerospace-grade platens ensure ±0.5% temperature homogeneity.

- Emergency protocols and dual protection doors eliminate operational hazards.

- Scalability:

- Modular designs support workspace upgrades (120x120mm to 500x500mm).

- 220V/110V compatibility and CE-certified electronics ease global deployment.

Industries gain competitive edges through accelerated prototyping, reduced scrap rates, and digitized process traceability—translating to faster ISO validation and higher ROI. For labs prioritizing precision, safety, and throughput, this machine sets the benchmark.

Ready to elevate your lab’s capabilities? Contact KINTEK for a tailored solution demo!

Technical specifications

| Parameter | 120×120 | 180×180 | 200×200 | 300×300 | 400×400 | 500×500 |

|---|---|---|---|---|---|---|

| Heating temperature/power | Room temperature -300°C/1.6KW Room temperature -500°C/2KW Room temperature -800°C/4.5KW |

Room temperature -300°C/2.2KW Room temperature -500°C/3.4KW Room temperature -800°C/ 6KW |

Room temperature -300°C/2.2KW Room temperature -500°C/3.4KW Room temperature -800°C/ 6KW |

Room temperature -300°C/3KW Room temperature -500°C/4.5KW |

Room temperature -300°C/4KW Room temperature -500°C/ 6KW |

Room temperature -300°C/10KW Room temperature -500°C/ 16KW |

| Heating | (300°C), (500°C), (800°C) | (300°C), (500°C), 6KW (800°C) | 2.2KW (300°C), 3.4KW (500°C), 6KW (800°C) | 3KW (300°C), 4.5KW (500°C) | 4KW (300°C), 6KW (500°C) | 1 |

| Pressure range | 0.01-5.0 tons | 0.01-25 tons | 0.01-25 tons | 0.01-30 tons | 0.01-50 tons | 0.01-60 tons |

| Pressure accuracy | 0.01 tons | |||||

| Display | 7-inch (IPS HD) touch screen | |||||

| Metal buttons | Silver-plated contacts, >100,000 cycles | |||||

| Safety protection | Acrylic door + emergency stop | |||||

| Graphs | Displays operation graph, USB Excel export | |||||

| Program control | Up to 18 steps | |||||

| Water cooling | Manual + automatic rapid cooling | |||||

| Speed adjustment | Adjustable pressure/temperature ramp rates | |||||

| Remote control | Optional computer required | |||||

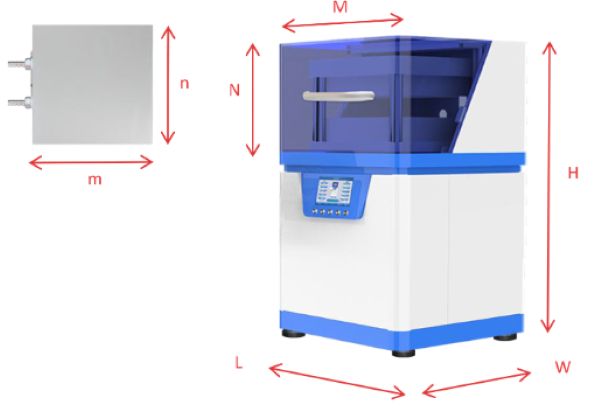

| Tablet size | 120 x 120 (m×n) | 180 x 180 mm(m×n) | 200 x 200 mm(m×n) | 300 x 300 mm(m×n) | 400 x 400 mm(m×n) | 500 x 500 mm(m×n) |

| Workspace | 130 x 55 mm | 210 x 65 mm | 210 x 65 mm | 320 x 70 mm | 420 x 90 mm | 520 x 100 mm |

| Power supply | 220V/110V (customizable) | |||||

| Product dimensions/weight | 350x350x580 mm / 75 kg | 480x480x750 mm / 200 kg | 480x480x750 mm / 200 kg | 580x580x1180 mm / 580 kg | 680x680x1280 mm / 1130 kg | 780x780x1350 mm / 1808 kg |

| Packaging dimensions/weight | 725x620x890 mm / 84 kg | 725x620x890 mm / 236 kg | 725x620x890 mm / 236 kg | 900x800x1400 mm / 650 kg | 900x800x1400 mm / 1200 kg | 900x800x1400 mm / 1920 kg |

Trusted by Industry Leaders

FAQ

What Are The Advantages Of Using A Hydraulically Heated Laboratory Press?

How Do Electric Laboratory Presses Work?

What Does A Hydraulic Lab Heat Press Do?

What Are The Advantages Of Using Electric Laboratory Presses?

What Types Of Samples Or Materials Can Be Processed In A Hydraulically Heated Laboratory Press?

What Are The Applications Of Electric Laboratory Presses?

How Does A Hydraulically Heated Laboratory Press Work?

What Considerations Should Be Taken When Selecting An Electric Laboratory Press?

How Can The Performance Of A Hydraulically Heated Laboratory Press Be Optimized?

4.9 / 5

This machine is a game-changer! The precision and speed are unmatched. Worth every penny!

4.8 / 5

Incredible quality and durability. It’s like having a lab assistant that never tires!

4.7 / 5

Fast delivery and easy setup. The advanced features make our research so much more efficient.

4.9 / 5

The technological advancements in this press are mind-blowing. A must-have for any serious lab.

4.8 / 5

Superb value for money. The programmable workflows save us hours of manual work.

4.7 / 5

The safety features are top-notch. We feel completely secure using it daily.

4.9 / 5

The thermal management is exceptional. Perfect for our high-temperature applications.

4.8 / 5

Robust construction and reliable performance. It’s a cornerstone of our lab now.

4.7 / 5

The interface is so intuitive. Even our newest team members can operate it with ease.

4.9 / 5

The scalability is fantastic. It grows with our needs, making it a long-term investment.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

The Automatic High Temperature Heat Press is a sophisticated hydraulic hot press designed for efficient temperature control and product quality processing.

Manual Lab Heat Press

Manual hydraulic presses are mainly used in laboratories for various applications such as forging, molding, stamping, riveting and other operations. It allows the creation of complex shapes while saving material.

Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

Enhance your lab's precision with our lab press for vacuum box. Press pills and powders with ease and precision in a vacuum environment, reducing oxidation and improving consistency. Compact and easy to use with a digital pressure gauge.

Touchscreen Automatic Vacuum Heat Press

Precision vacuum heat press for labs: 800°C, 5-ton pressure, 0.1MPa vacuum. Ideal for composites, solar cells, aerospace.

30T 40T Split Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

Discover our split automatic heated lab press 30T/40T for precise sample preparation in material research, pharmacy, ceramics, and electronics industries. With a small footprint and heating up to 300°C, it's perfect for processing under vacuum environment.

Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

The High Temperature Hot Press is a machine specifically designed for pressing, sintering and processing materials in a high temperature environment. It is capable of operating in the range of hundreds of degrees Celsius to thousands of degrees Celsius for a variety of high temperature process requirements.

Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

Efficiently prepare samples with our Automatic Lab Cold Isostatic Press. Widely used in material research, pharmacy, and electronic industries. Provides greater flexibility and control compared to electric CIPs.

Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

Produce dense, uniform parts with improved mechanical properties with our Electric Lab Cold Isostatic Press. Widely used in material research, pharmacy, and electronic industries. Efficient, compact, and vacuum-compatible.

Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

Reduce forming pressure & shorten sintering time with Vacuum Tube Hot Press Furnace for high-density, fine-grain materials. Ideal for refractory metals.

Vacuum Hot Press Furnace Machine Heated Vacuum Press

Discover the advantages of Vacuum Hot Press Furnace! Manufacture dense refractory metals & compounds, ceramics, and composites under high temp and pressure.

Small Lab Rubber Calendering Machine

Small lab rubber calendering machine is used for producing thin, continuous sheets of plastic or rubber materials. It is commonly employed in laboratories, small-scale production facilities, and prototyping environments to create films, coatings, and laminates with precise thickness and surface finish.

Small Injection Molding Machine for Lab Use

The small injection molding machinehas fast and stable movements; good controllability and repeatability, super energy saving; the product can be automatically dropped and formed; the machine body is low, convenient for feeding, easy to maintain, and no height restrictions on the installation site.

Laboratory Planetary Ball Mill Cabinet Planetary Ball Milling Machine

The vertical cabinet structure combined with ergonomic design enables users to obtain the best comfortable experience in standing operation. The maximum processing capacity is 2000ml, and the speed is 1200 revolutions per minute.

Laboratory Horizontal Planetary Ball Mill Milling Machine

Improve sample uniformity with our Horizontal Planetary Ball Mills. KT-P400H reduces sample deposition and KT-P400E has multi-directional capabilities. Safe, convenient and efficient with overload protection.

Laboratory Planetary Ball Mill Rotating Ball Milling Machine

KT-P400E is a desktop multi-directional planetary ball mill with unique grinding and mixing capabilities. It offers continuous and intermittent operation, timing, and overload protection, making it ideal for various applications.

Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

KT-VD200 can be used for sieving tasks of dry and wet samples in the laboratory. The screening quality is 20g-3kg. The product is designed with a unique mechanical structure and an electromagnetic vibrating body with a vibration frequency of 3000 times per minute.

Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

The single-punch electric tablet press is a laboratory-scale tablet press suitable for corporate laboratories in pharmaceutical, chemical, food, metallurgical and other industries.

Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

This machine is a single-pressure automatic rotating, continuous tableting machine that compresses granular raw materials into various tablets. It is mainly used for tablet production in the pharmaceutical industry, and is also suitable for chemical, food, electronics and other industrial sectors.

Cold Isostatic Pressing Machine CIP for Small Workpiece Production 400Mpa

Produce uniformly high-density materials with our Cold Isostatic Press. Ideal for compacting small workpieces in production settings. Widely used in powder metallurgy, ceramics, and biopharmaceutical fields for high-pressure sterilization and protein activation.

Electric Split Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

Split cold isostatic presses are capable of providing higher pressures, making them suitable for testing applications that require high pressure levels.

Related Articles

The Physics of Flawless Materials: Deconstructing the Hydraulic Hot Press

Discover how the synergy of Pascal's Law and thermal energy in a hydraulic hot press enables precise, repeatable material bonding and forming.

Why Your Lab-Scale Bonding Fails: The Hidden Physics of Heat and Pressure

Struggling with delamination or voids in your laminates and composites? Discover the root cause and how to finally achieve perfect, repeatable results.

Beyond Brute Force: The Controlled Physics of Perfect Material Bonding

A hot press isn't just a heater and a press. It's a system where controlled heat and force unite for flawless, repeatable material bonding.

Why Your Molded Parts Fail: The Hidden Truth About Heat and Pressure

Struggling with warped or inconsistent parts? Learn why pressure isn't the problem and how precise thermal control in a hydraulic press is the key.

Why Your Hot Press Samples Fail: The Hidden Culprit in Material R&D

Tired of failed composite or laminate samples? Discover the hidden cause of inconsistent results and how the right lab hot press ensures repeatable success.

Pressure and Heat: Forging Certainty into Matter

A hot press doesn't just shape materials; it eliminates hidden flaws and forges atomic-level trust. Learn the physics of material integrity.

Why Your Lab Equipment Suddenly Fails: It’s Not a Quality Issue, It’s a Physics Problem

Frustrated by lab equipment failures? Discover the hidden physics of pressure vs. strength that causes them and learn how precision-engineered solutions prevent delays.

Why Your Composite and Polymer Parts Keep Failing: The Secret Is Simultaneous Heat and Pressure

Struggling with inconsistent composite or polymer bonding? Discover why separate heating and pressing fails and how a hot hydraulic press ensures repeatable, high-quality results.

Why Your Lab Press Fails: It's Not the Tonnage, It's the Steel

Discover the hidden reason your hydraulic press gives inconsistent results. Learn why the choice of steel is more critical than tonnage for safety and accuracy.

The Pressure-Temperature Dialogue: Mastering Material Consolidation

Learn why hot pressing isn't about fixed values, but a precise dialogue between temperature, pressure, and your material's unique properties.

The Hidden Flaw: Why Your High-Performance Metal Parts Fail and How to Achieve True Material Integrity

Your 3D-printed or cast metal parts look perfect but fail unexpectedly? Discover the hidden cause of inconsistency and how Hot Isostatic Pressing (HIP) ensures total reliability.

Beyond Max Pressure: Why Your Hot Isostatic Pressing (HIP) Results Are Inconsistent—And How to Fix Them

Struggling with inconsistent HIP results? Discover why max pressure isn't the answer and how mastering pressure, temperature, and time is the key to perfect material densification.