You’ve meticulously prepared your sample. The procedure is perfect. You place it in the lab press, apply the specified force, and... the resulting pellet cracks, or the material isn't properly consolidated. You run the test again, and the result is different. After weeks of troubleshooting your materials and methods, a frustrating thought creeps in: what if the problem isn’t the sample, but the machine itself?

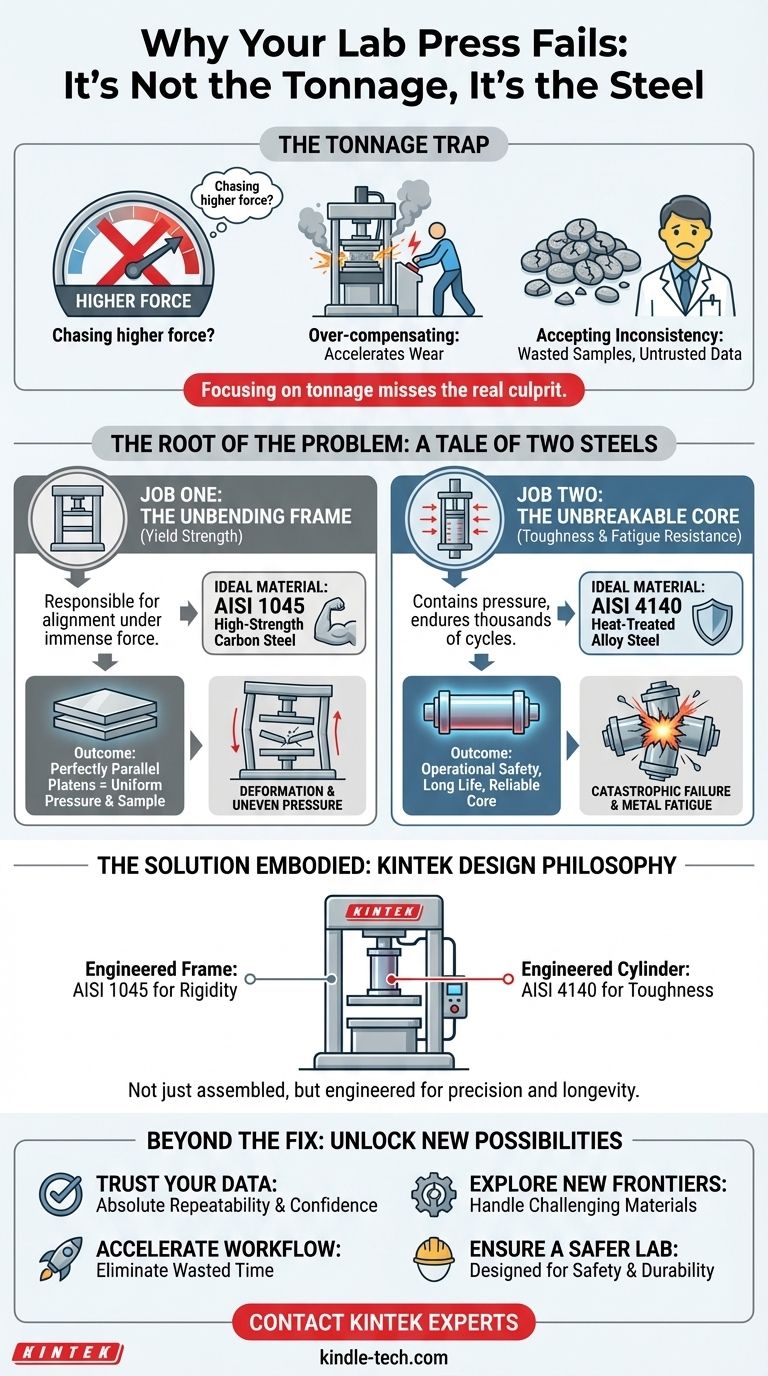

The Tonnage Trap: Why More Force Isn't the Answer

When a lab press delivers inconsistent results or shows early signs of wear, the common reaction is to scrutinize the tonnage rating. The prevailing logic is that a higher-tonnage press must be better, stronger, and more reliable. This leads many labs down a frustrating and costly path:

- Chasing higher force: Believing their current press is "underpowered," they seek a replacement with a higher number on the dial, only to face similar issues of inconsistency down the line.

- Over-compensating: Operators apply more force than necessary, hoping to brute-force a consistent result, which only accelerates wear and tear on the machine's components.

- Accepting inconsistency: The team learns to "work around" the press's quirks, leading to wasted samples, repeated work, and data that is difficult to trust.

The commercial consequences of this trap are severe. Valuable research hours are lost, expensive sample materials are ruined, and project timelines are delayed. Most critically, it introduces a fundamental variable into your experiments, undermining the integrity of your results. This happens because focusing on tonnage misses the real culprit.

The Root of the Problem: A Tale of Two Steels

A hydraulic press is not one single piece of metal; it’s a system of components, each facing a different kind of physical stress. The secret to a reliable press isn’t just its maximum force, but whether it is engineered with the right material for each specific job. The failure to do so is the root cause of inconsistency and premature failure.

A press has two primary jobs that require two fundamentally different material properties.

Job One: The Unbending Frame (Yield Strength)

The frame (whether an H-frame or C-frame) is responsible for holding everything in perfect alignment under immense force. Its primary enemy is deformation. If the frame bends, even microscopically, the platens will no longer be perfectly parallel. This leads directly to uneven pressure on your sample, causing cracks and inconsistent density.

The solution is a material with extremely high yield strength—the ability to resist permanent bending. For this, high-strength carbon steels like AISI 1045 are ideal. They provide the absolute rigidity necessary for precision work, ensuring the force you dial in is the force your sample actually receives, uniformly and repeatably.

Job Two: The Unbreakable Core (Toughness & Fatigue Resistance)

The hydraulic cylinder is the heart of the press. It doesn't just need to be rigid; it needs to contain enormous internal hydraulic pressure without bursting. Furthermore, it must endure thousands of pressure cycles over its lifetime. Its primary enemy is catastrophic failure and metal fatigue.

Here, yield strength alone is not enough. The material must also have exceptional toughness—the ability to absorb energy and resist shattering. This is why critical components like cylinders demand superior, heat-treated alloy steels like Chromium-Molybdenum (AISI 4140). This material is engineered to handle extreme, cyclical pressure safely, providing a crucial margin of safety and ensuring long-term operational integrity.

The "common solutions" fail because a press built from a single, inadequate type of steel cannot perform both of these jobs correctly. A frame made from a soft steel will bend, and a cylinder made from a brittle one is a safety hazard waiting to happen.

The Solution Embodied: Engineered, Not Just Assembled

To permanently solve the problem of inconsistency and unreliability, you need a tool built on a deep understanding of these dueling physical demands. A press should not be a commodity judged by a single number, but an engineered instrument where every component's material is precisely chosen for its specific task.

This is the KINTEK design philosophy. Our hydraulic presses are not just assembled to meet a tonnage rating; they are engineered for precision and longevity from the ground up.

- For the Frame: We utilize high-yield-strength carbon steel to ensure your press remains perfectly rigid, delivering consistent and parallel force application every single time. This directly eliminates the root cause of uneven sample preparation.

- For the Cylinder: We insist on heat-treated alloy steels for the hydraulic core. This addresses the fundamental need for toughness and fatigue resistance, guaranteeing operational safety and a long service life even under heavy use.

Our presses are the embodiment of this two-steel solution. They are designed to master force, not just exert it, providing you with a stable, reliable platform for your most important work.

Beyond the Fix: What a Truly Dependable Press Unlocks

When your hydraulic press ceases to be a variable and becomes a reliable constant, it fundamentally changes what’s possible in your lab. You are no longer just avoiding problems; you are opening the door to new opportunities.

With a press engineered for material integrity, you can:

- Trust Your Data: Achieve a level of repeatability that gives you absolute confidence in your results, whether for quality control or foundational research.

- Explore New Frontiers: Work with more challenging, high-strength materials and advanced composites, knowing your equipment can handle the pressure with precision.

- Accelerate Your Workflow: Eliminate the time and resources wasted on failed tests and inconsistent sample prep, moving your projects forward faster.

- Ensure a Safer Lab: Operate with the peace of mind that comes from using equipment designed with safety and durability as its core principles.

This isn't just about avoiding equipment failure; it's about building a foundation of reliability for your most critical work. If you're tired of questioning your equipment and want to discuss how an engineered press can solve your specific sample preparation challenges, our team is here to help. Contact Our Experts.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Laboratory Heat Press Machine

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

Related Articles

- Sample preparation and unloading method of electric tablet press

- Why Your Lab Pellets Crack: The Hidden Physics of a Perfect Press

- Operating of Automatic Lab xrf Pellet Press

- The Benchtop KBr Pellet Press: An Efficient Tool for Laboratory Use

- Operating steps and precautions for electric tablet press